Batch detection tool and method for fuel cell bipolar plate leakage

A fuel cell and batch detection technology, which is applied to fuel cell parts, detects the appearance of fluid at the leakage point, and uses liquid/vacuum to measure the liquid tightness, etc., which can solve the problem of inability to visually determine the leakage on the plate The severity of point leakage, the inability to locate the leakage position of the plate, and the inadvisability of mass production have achieved the effects of shortening the detection cycle, ensuring the one-time pass rate, and improving screening efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

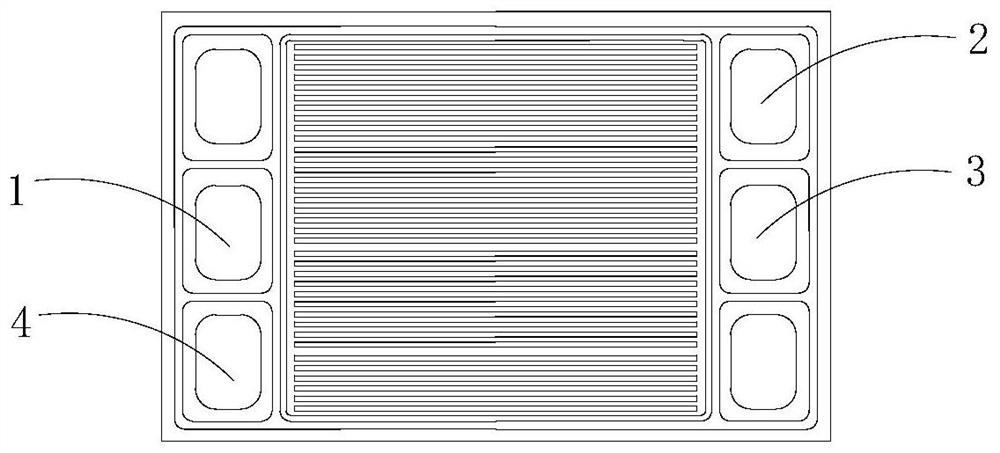

[0032] A batch detection tool for fuel cell bipolar plate leakage, the structure of the bipolar plate is as follows figure 1 As shown, it includes three inlets and three outlets and various fluid channels. The cooling fluid inlet 1, the air inlet 2, the cooling fluid outlet 3 and the air outlet 4 and the cooling fluid inlet 1 and the cooling fluid outlet 3 are used in the detection of this application. Cooling fluid channel, the air flow channel connecting the air inlet 2 and the air outlet 4.

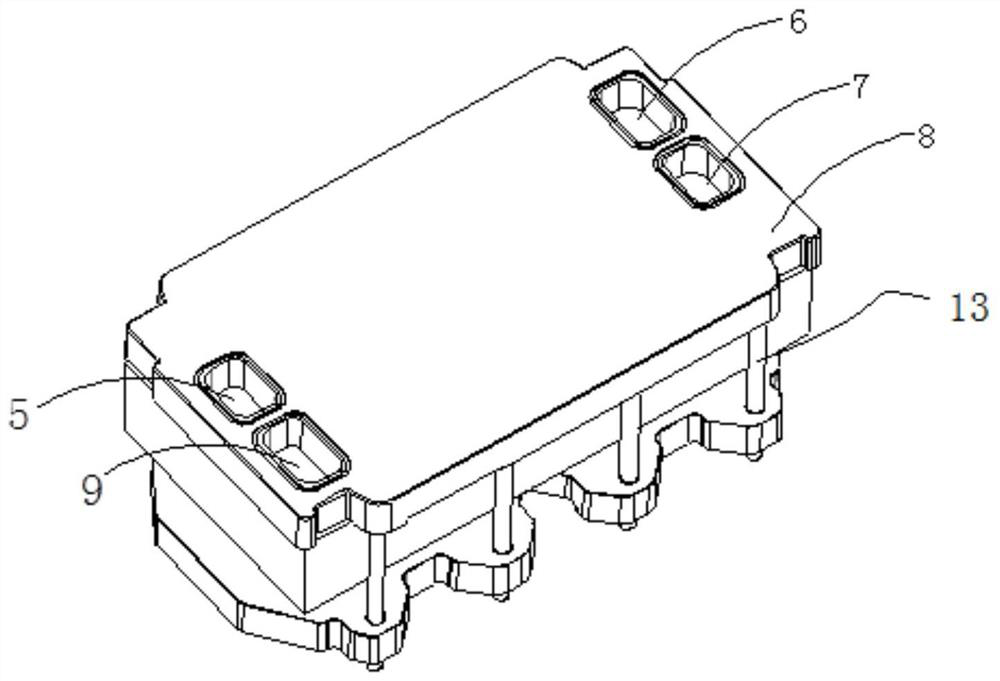

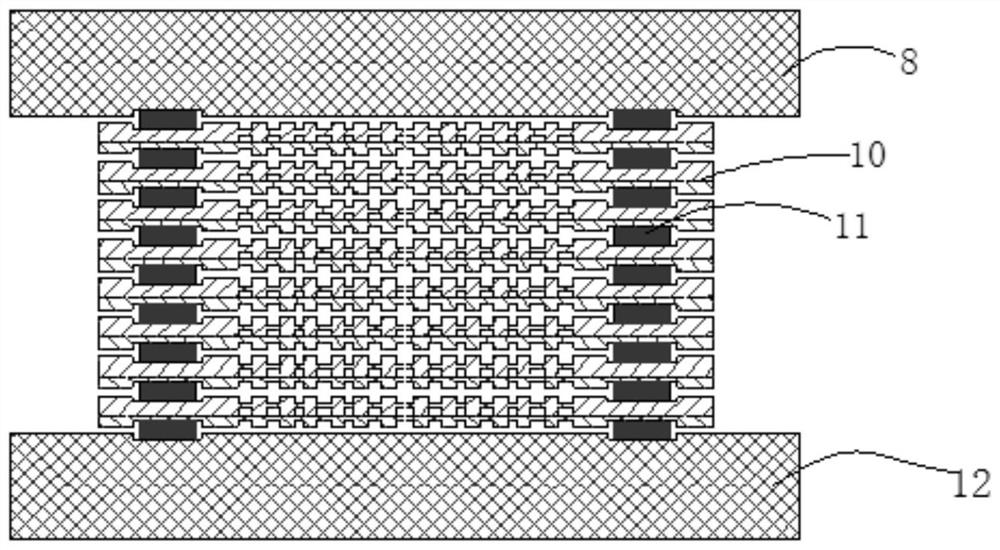

[0033] Such as Figure 2-3 As shown, the tooling includes an upper end plate 8, a lower end plate 12, and a tie rod 13. A plurality of bipolar plates 10 are stacked between the upper end plate 8 and the lower end plate 12, and are fixed by the tie rod 13. Adjacent bipolar plates 10 and The bipolar plate 10 and the upper end plate 8 and the lower end plate 12 are sealed by a seal 11, and the upper end plate 8 and the lower end plate 12 are provided with a fluorescent developer solution...

Embodiment 2

[0043]The water-soluble fluorescent agent used in this embodiment is a commercially available phenylpyrazoline derivative containing 200 ppm.

[0044] There are two bipolar plates 10 stacked between the upper end plate 8 and the lower end plate 12, the temperature of the fluorescent developer solution and the hot air pumped into the tooling are both 40°C, and the fluid pressure in the cooling fluid channel is kept at 100kPa. Flow velocity is 0.4m / s, leaves standstill 7 days, all the other are with embodiment 1.

Embodiment 3

[0046] The water-soluble fluorescent agent used in this example is a commercially available coumarin derivative containing 2000 ppm.

[0047] There are 200 bipolar plates 10 stacked between the upper end plate 8 and the lower end plate 12, the temperature of the fluorescent developer solution and the hot air pumped into the tooling are both 60°C, and the fluid pressure in the cooling fluid channel is maintained at 200kPa, Flow velocity is 1m / s, leaves standstill 1 day, all the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com