Nitrogen-doped carbon-coated Ru nano-catalyst and application thereof in electrochemical deuterium evolution reaction

A nano-catalyst, nitrogen-doped carbon technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc. The effect of improving reaction performance and large current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1 The preparation method of a nitrogen-doped carbon-coated Ru nanocatalyst (loading capacity 2.5%) is as follows:

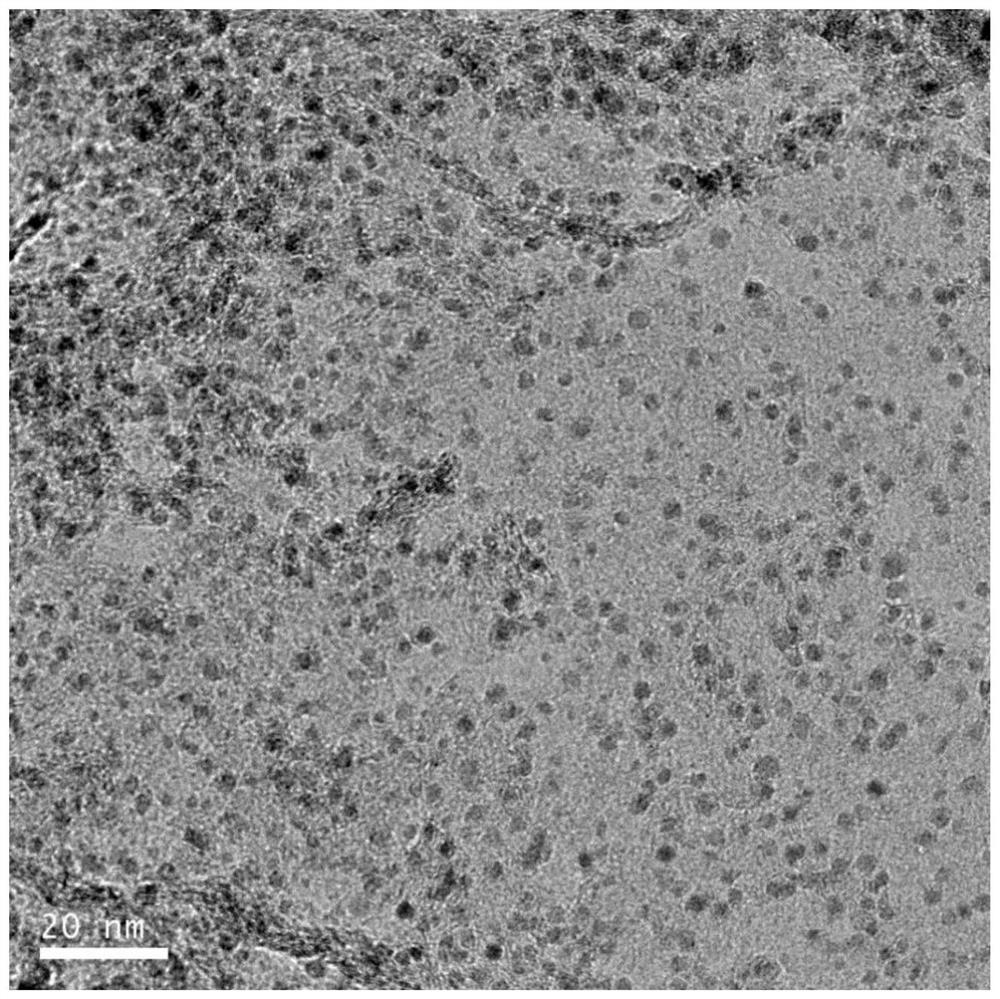

[0027] Accurately weigh 40 mg of ammonium sulfate, 40 mg of glucose and 1.6 g of dicyandiamide in a mortar, mix them uniformly first, then add 4.5 mg of ruthenium trichloride into it, grind for 30 min with a grinding rod to obtain a uniformly mixed mixture, pour the mixture into the crucible, and then the crucible was placed in a tube furnace, under N 2 Atmosphere with 3 o C / min heating rate from room temperature to 800 o C, then calcine at constant temperature for 1 h and then cool down to room temperature naturally. The nitrogen-doped carbon-coated Ru nanocatalyst can be prepared by taking out the calcined product and grinding it evenly. Carry out TEM characterization of the nitrogen-doped carbon-coated Ru nanocatalyst prepared in this example, the characterization results are as follows figure 2 shown, from figure 2 It can be seen that th...

Embodiment 2

[0028] Example 2 The preparation method of a nitrogen-doped carbon-coated Ru nanocatalyst (loading capacity 5%) is as follows:

[0029] Accurately weigh 40 mg of ammonium sulfate, 40 mg of glucose and 1.6 g of dicyandiamide in a mortar, mix them uniformly first, then add 9.0 mg of ruthenium trichloride into it, and grind with a grinding rod for 30 minutes to obtain a uniformly mixed mixture, pour the mixture into the crucible, and then the crucible was placed in a tube furnace, under N 2 Atmosphere with 3 o C / min heating rate from room temperature to 800 o C, then calcine at constant temperature for 1 h and then cool down to room temperature naturally. The nitrogen-doped carbon-coated Ru nanocatalyst can be prepared by taking out the calcined product and grinding it evenly.

Embodiment 3

[0030] Example 3 The preparation method of a nitrogen-doped carbon-coated Ru nanocatalyst (loading capacity 7.5%) is as follows:

[0031]Accurately weigh 40 mg of ammonium sulfate, 40 mg of glucose and 1.6 g of dicyandiamide in a mortar, mix them uniformly first, then weigh 13.5 mg of ruthenium trichloride and add them, grind for 30 min with a grinding rod to obtain a uniformly mixed mixture, pour the mixture into the crucible, and then the crucible was placed in a tube furnace, under N 2 Atmosphere with 3 o C / min heating rate from room temperature to 800 o C, then calcine at constant temperature for 1 h and then cool down to room temperature naturally. The nitrogen-doped carbon-coated Ru nanocatalyst can be prepared by taking out the calcined product and grinding it evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com