Anti-cracking asphalt and preparation method thereof

An anti-cracking and asphalt technology, used in building components, building thermal insulation materials, buildings, etc., can solve the problems of insufficient asphalt toughness, fracture, asphalt pavement deformation, etc., to improve compatibility, improve connection strength, and improve service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

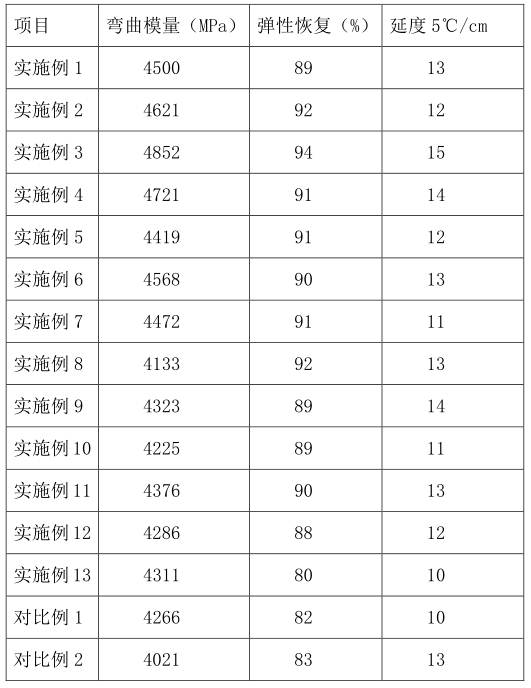

[0043] Embodiment 1-Example 6 all adopt the same preparation method to prepare anti-cracking asphalt, the only difference is that the dosage of each raw material component is different, see Table 2 for details:

[0044] The dosage of each raw material component in the embodiment 1-embodiment 6 of table 2

[0045]

[0046] In Example 1-Example 6, the modifiers are all mixed with o-diallyl bisphenol A and bisphenol A epoxy resin in a weight ratio of 40:60.

[0047] All above-mentioned embodiments all adopt following preparation method to make:

[0048] S1. According to the ratio, dissolve the antioxidant into the organic solvent ethyl acetate to prepare an antioxidant solution, mix the base asphalt with the antioxidant solution, heat and stir at a speed of 60r / min for 60min, and the stirring temperature is 75°C to obtain a grade mixture;

[0049] S2. According to the proportion, add a modifier to the primary mixture, heat and stir at a speed of 120r / min for 40min, and the s...

Embodiment 7

[0052] The difference between this embodiment and embodiment 3 is that the modifier is formed by mixing o-diallyl bisphenol A and bisphenol A type epoxy resin with a weight ratio of 35:70.

Embodiment 8

[0054]The only difference between this embodiment and embodiment 3 is that the modifier is formed by mixing o-diallyl bisphenol A and bisphenol A type epoxy resin with a weight ratio of 35:60.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com