U-shaped clamp for installing light partition wall

A U-shaped, lightweight technology, applied in the field of U-shaped cards, can solve problems such as inappropriate rush projects, and achieve the effects of saving construction time, enhancing safety, and increasing connectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

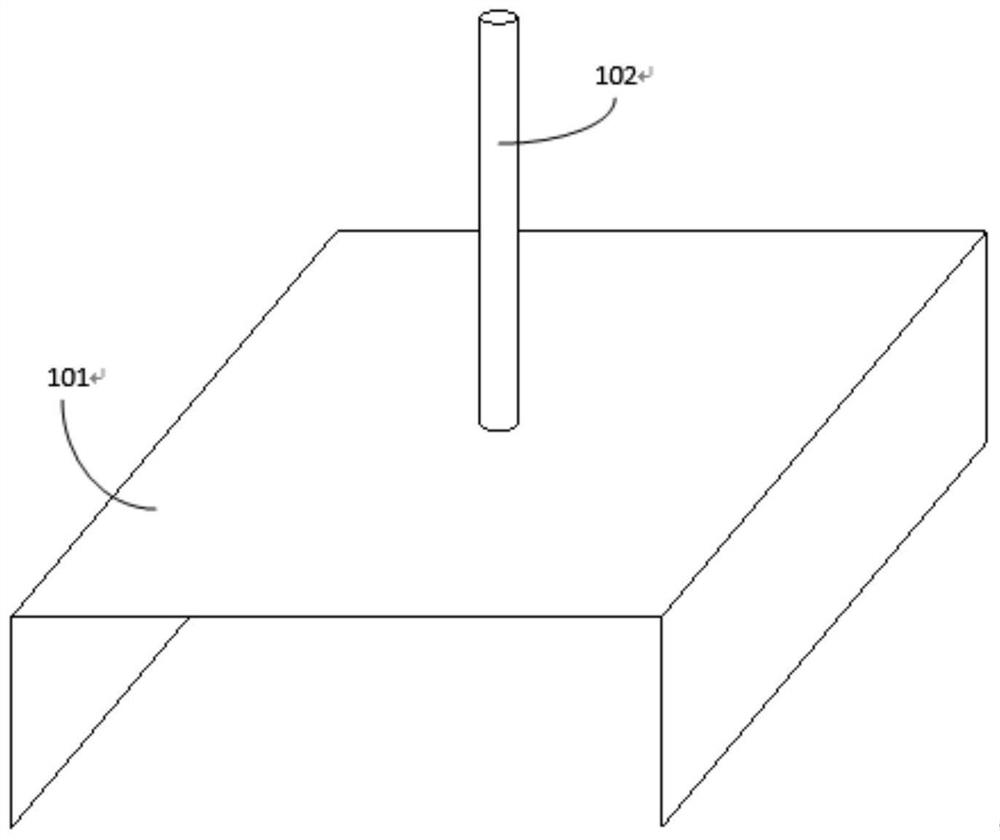

[0023] refer to figure 1 As shown, the present invention discloses a U-shaped card for installing a lightweight partition wall. The U-shaped card includes a buckle 101 and a plurality of limit pins 102 disposed on the back of the buckle 101 .

[0024] Preferably, the buckle 101 has a U-shaped structure. When installing the lightweight partition wall, a lightweight partition wall is clipped into the U-shaped groove of the buckle 101 , and the limiting nail 102 is located at the position to be poured. Construct the column's template cavity. In the process of pouring the structural column in the later stage, the limit nail can be poured into the concrete of the structural column. Since the post-construction column is poured, the concrete and the limit nail 102 are more closely connected during the forming process, which enhances the safety of the stability of the entire lightweight wall.

[0025] In addition, through the structural design of the U-shaped card of the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com