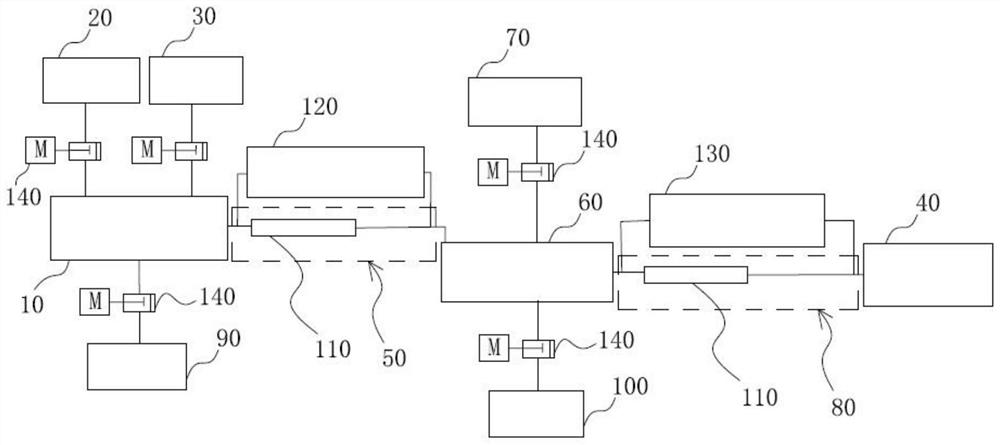

Ternary rare earth catalyst continuous aging device

A rare earth catalyst and aging device technology, applied in the field of rare earth butadiene rubber preparation, can solve the problems of inability to age continuously, large difference in catalyst activity between tanks, unsuitable for continuous production of rare earth butadiene rubber, etc., and achieve consistent activity and precision high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

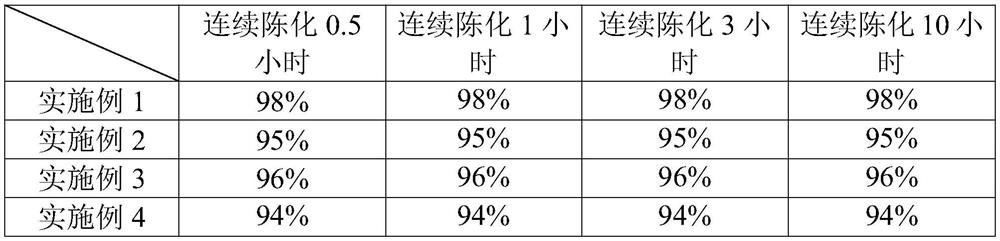

Examples

Embodiment 1

[0062] Carry out preparatory work before driving the device. Introduce public works (water, electricity, gas, etc.), and then carry out pressure air tightness test on equipment and pipelines, and purge with nitrogen to ensure that the device does not leak and is in an oxygen-free state.

[0063] Start the first pipeline homogeneous pump, and start the metering pump of the first catalyst feeding unit, the metering pump of the second catalyst feeding unit and the metering pump of the first solvent feeding unit, neodymium neodecanoate, diethylhydrogen Aluminum and normal hexane are transported to the first pipeline homogeneous pump, wherein, the mol ratio of neodymium neodecanoate and diethylaluminum hydride is 1:30, and the feeding flow rate of controlling neodymium neodecanoate is 0.77L / h, and diethylaluminum hydride The feed flow rate of ethylaluminum was 1.67 L / h, and the feed flow rate of n-hexane was 9.34 L / h. Neodymium neodecanoate, diethylaluminum hydride and n-hexane wer...

Embodiment 2

[0067] The difference between embodiment 2 and embodiment 1 is that the mol ratio of neodymium neodecanoate and diethylaluminum hydride is 1:20, and the mol ratio of neodymium neodecanoate and diethylaluminum chloride is 1:2, and the new The feed flow rate of neodymium caprate is 0.77 / h, the feed flow rate of diethylaluminum hydride is 1.11L / h, the feed flow rate of n-hexane in the first solvent feed unit is 9.9L / h, diethyl chloride The feeding amount of base aluminum is 0.8L / h, and the flow rate of n-hexane in the second solvent feeding unit is 5.08L / h.

Embodiment 3

[0069] The only difference between Example 3 and Example 1 is that the feed flow rate of n-hexane in the first solvent feed unit is 21.11 L / h, and the aging time of the first mixed liquid in the binary aging pipeline is 5 minutes ; The normal hexane flow rate in the second solvent feeding unit is 10.78L / h, and the aging time of the second mixed liquid in the three-way aging pipeline is 10 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com