A method for connecting skutterudite thermoelectric materials and electrodes using a high thermal stability alloy composite interlayer

A composite intermediate layer and thermoelectric material technology, which is applied in the manufacture/processing of thermoelectric devices, thermoelectric device parts, welding equipment, etc., can solve the problems of poor thermal stability of connection joints and large contact resistance, and achieve low contact resistivity, The effect of high thermal stability and simple process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

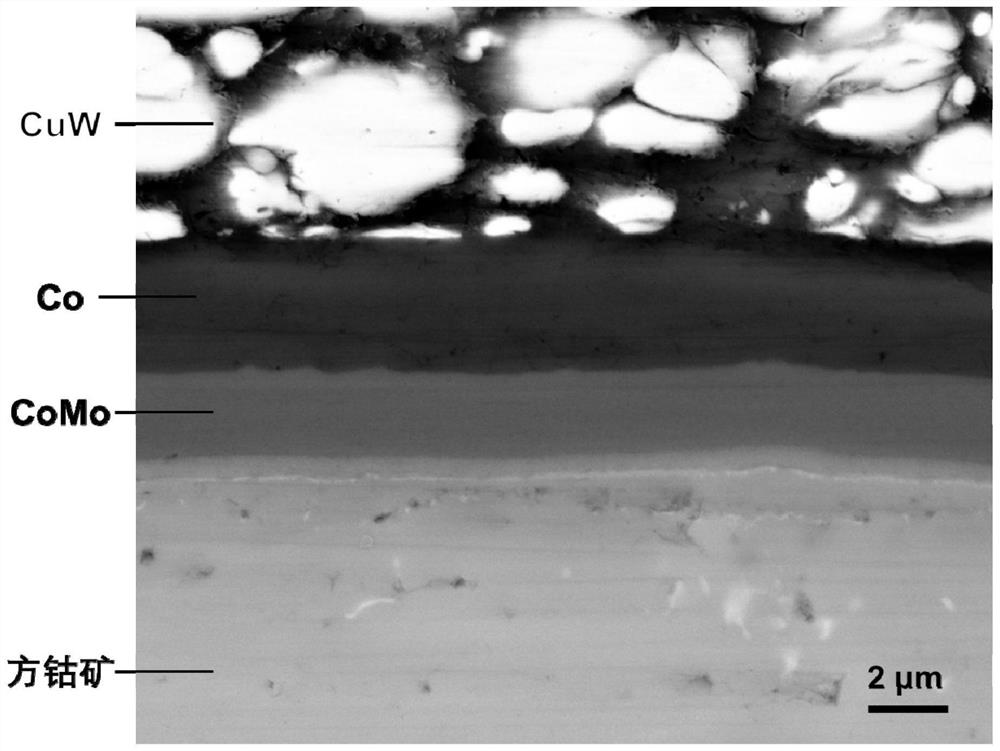

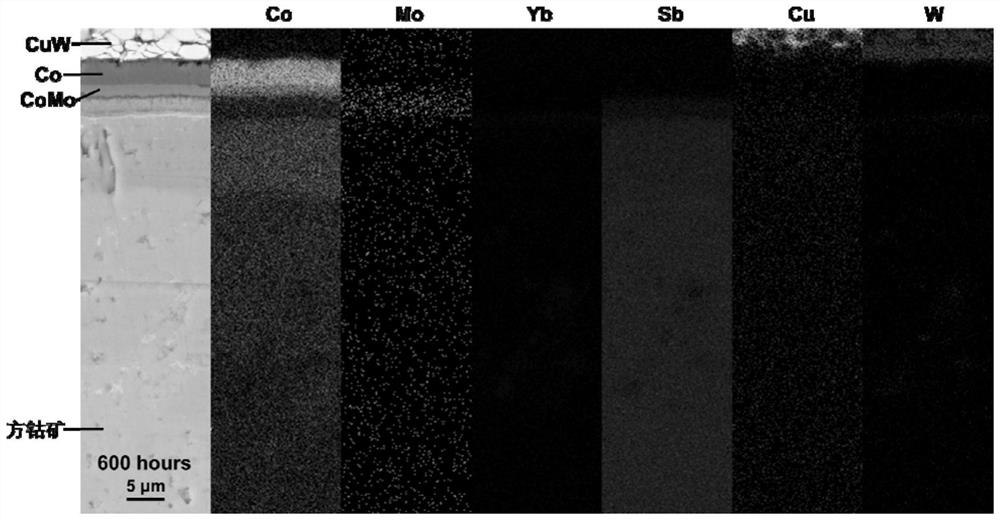

[0019] Embodiment 1: In this embodiment, the method for connecting the skutterudite thermoelectric material and the electrode using the high thermal stability alloy composite intermediate layer is carried out according to the following steps:

[0020] 1. Clean the surfaces to be welded of the cobalt ore thermoelectric materials and electrodes;

[0021] 2. Use electroplating or physical vapor deposition to prepare an intermediate connecting layer on the surface of the electrode, and prepare a diffusion barrier layer on the surface of the intermediate connecting layer; or prepare an intermediate connecting layer on the surface of the electrode, and prepare a diffusion barrier layer on the surface of the skutterudite thermoelectric material Or prepare a diffusion barrier layer on the surface of the skutterudite thermoelectric material, and prepare an intermediate connection layer on the surface of the diffusion barrier layer; then stack the obtained electrode and the skutterudite ...

specific Embodiment approach 2

[0029] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the cleaning process in step 1 is: firstly rinse with absolute ethanol, then place in acetone for ultrasonic cleaning for 5-30 minutes, and finally air dry.

specific Embodiment approach 3

[0030] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the electrodes in step 1 are metal electrodes or alloy electrodes;

[0031] The metal electrode material is Cu, Ni, Fe, Co or Cr;

[0032]The alloy electrode material is Cu-based alloy, Ni-based alloy, Fe-based alloy, Co-based alloy or Cr-based alloy;

[0033] The Cu-based alloy is CuW or CuMo; the Ni-based alloy is NiW, NiMo or NiCr; the Fe-based alloy is FeW, FeMo, FeCr or FeCoNi; the Co-based alloy is CoW, CoMo, CoCr, CoNi or CoFe; the Cr-based alloy is CrW, CrMo, CrCoNi or CrFeNi.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com