Spherical metal mineral powder, preparation method and application thereof and cement paste composition

A metal ore and cement slurry technology, which is applied to a cement slurry composition, the preparation of spherical metal ore powder, spherical metal ore powder and its application field, can solve the problem of easy aggregation of metal ore particles, reduce the particle size of metal ore powder, Problems such as high production energy consumption can achieve the effect of improving suspension stability, reducing drill pipe torque and low friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The first aspect of the present invention provides a kind of preparation method of spherical metal ore powder, wherein, comprise the following steps:

[0029] (1) In a Venturi mixer, the metal ore powder is mixed with compressed gas to obtain a mixture;

[0030] (2) Transfer the mixture into the burner, spray it out from the nozzle of the burner, contact with the fuel for combustion, and obtain spherical metal ore powder after condensation.

[0031] The inventors of the present invention have found that the D10 of the metal ore powder is 1-4 μm, the D50 is 2-6 μm, and the D90 is 6-10 μm. In particular, the D10 of the metal ore powder is 2-3 μm, the D50 is 3-5 μm, and the D90 When the thickness is 6-10 μm, the comprehensive effect is the most excellent.

[0032] According to the present invention, the particle size of the metal ore powder can be controlled by conventional methods. For example, grinding and / or classifying. The metal ore powder can be prepared from meta...

Embodiment 1

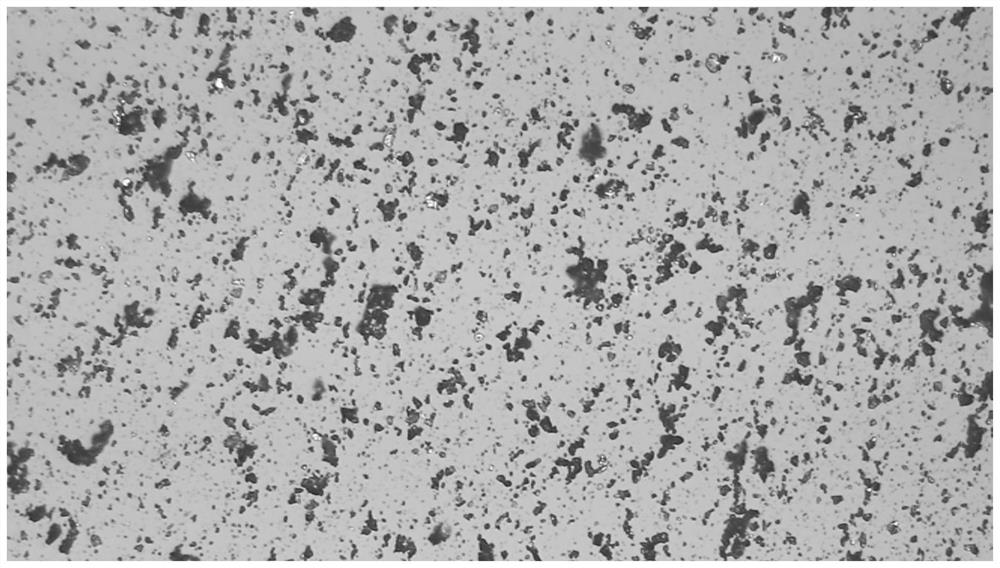

[0091] (1) Grinding and grading the hematite to obtain D10 is 3 μm, D50 is 5 μm, and D90 is 8 μm hematite powder, which is observed under a microscope (100 times magnification), and the result is as follows figure 1 shown;

[0092] (2) In the Venturi mixer, the hematite powder and compressed air are mixed to obtain a mixture; the mass flow ratio of the hematite powder and compressed air is 8g / L, and the pressure of the compressed air is 0.2MPa , the flow velocity is 8m / s, and the compressed air flows in a pulsed manner;

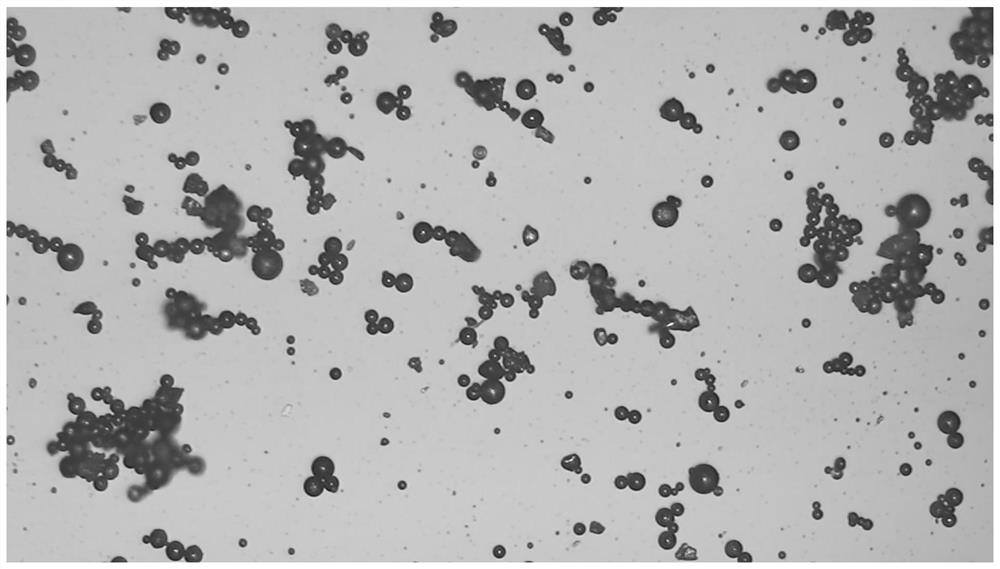

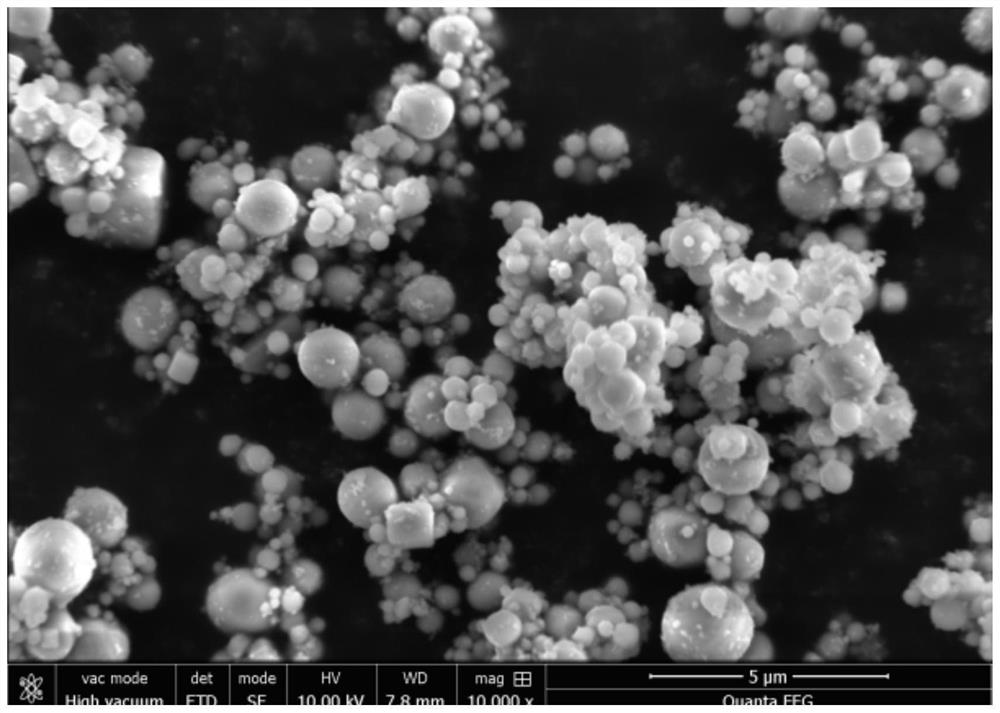

[0093] (3) The mixed material is transferred to the burner through the discharge section, and ejected from the nozzle of the burner, and burns in contact with natural gas (relative to the hematite powder per gram, the consumption of natural gas is 0.4g) , Condensation to obtain spherical metal ore powder, the velocity of the mixed material ejected from the burner nozzle is 6m / s, the flame temperature is 2000°C, and the flame is at an angle of 15°. Spherical...

Embodiment 2

[0097] (1) Grinding and classifying the hematite to obtain hematite powder with a D50 of 10 μm;

[0098] (2) In the Venturi mixer, the hematite powder and compressed air are mixed to obtain a mixture; the mass flow ratio of the hematite powder and compressed air is 14g / L, and the pressure of the compressed air is 0.2MPa , the flow velocity is 15m / s, and the compressed air flows in turbulent flow;

[0099] (3) The mixture is transferred from the burner, and ejected from the nozzle of the burner, with a volume ratio of 2.2:1 of natural gas and oxygen (with respect to every gram of hematite powder, natural gas The dosage is 0.6g) to contact, burn and condense to obtain spherical metal ore powder. The velocity of the mixture ejected from the nozzle is 10m / s, the flame temperature is 1600°C, and the flame is at an angle of 30°. Spherical hematite powder A2 was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com