Processing technology of dried noni fruits

A processing technology and dried fruit technology, which is applied in food processing, preservation of fruits/vegetables by dehydration, climate change adaptation, etc., can solve the problems of rotten flesh of sliced fruit, weak flesh of dried fruit, prolonged drying time, etc. It can shorten the drying time, improve the taste and taste, and prolong the shelf life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

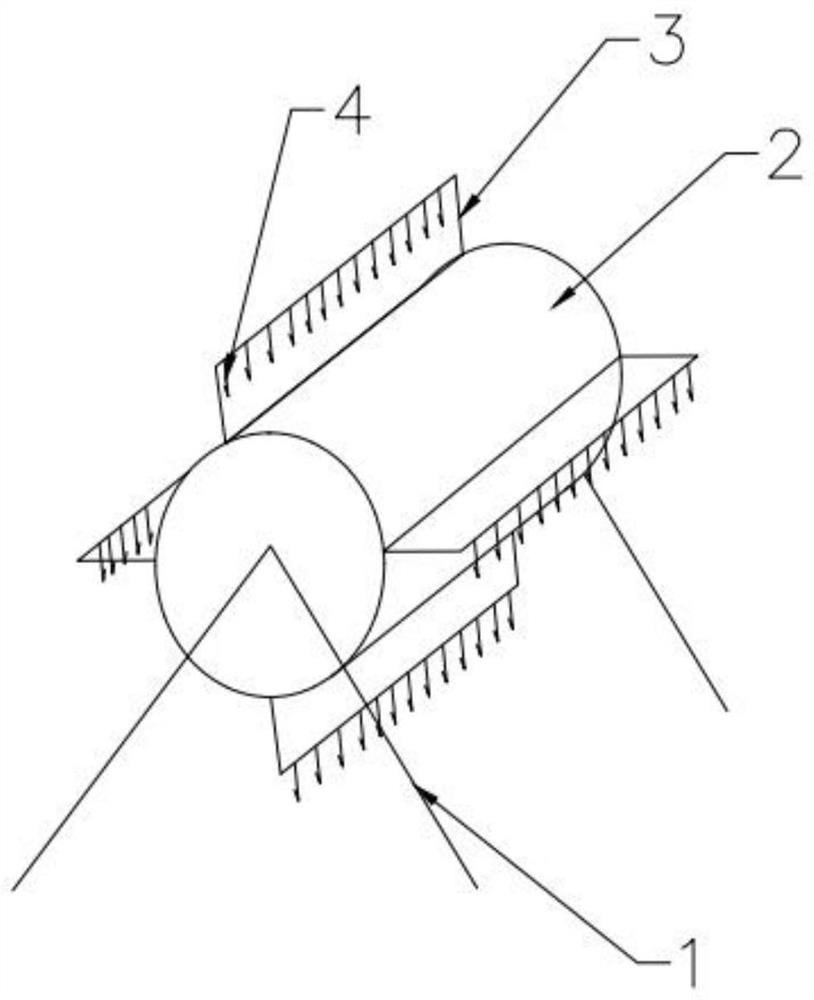

[0031] The present embodiment provides a kind of Noni dried fruit processing technology, comprises the following steps:

[0032] 101. Select ripe, mold-free, and pest-free noni fruits for cleaning, and pick noni fruits with a maturity of more than 90% from the orchard for picking, and avoid picking noni fruits with a maturity of less than 90% that taste bitter. The post-processing of the dried fruit will have a certain impact on the taste of the dried fruit. After picking, the Noni fruit with a suitable size, good appearance, no damage, and no pests is selected;

[0033] 102. Slice the cleaned Noni fruit between 5:00-8:00 p.m., preferably at 6:00 p.m., and take it out to dry at 6:00 or 7:00 the next morning after slicing at 6:00 p.m. The drying time is shortened, and the drying speed is accelerated. The thickness of the slice is 2mm-4mm, preferably 3mm. If it is too thick, it will affect the drying time. If it is too thin, it will not be easy to cut. Place the sliced Noni f...

Embodiment 2

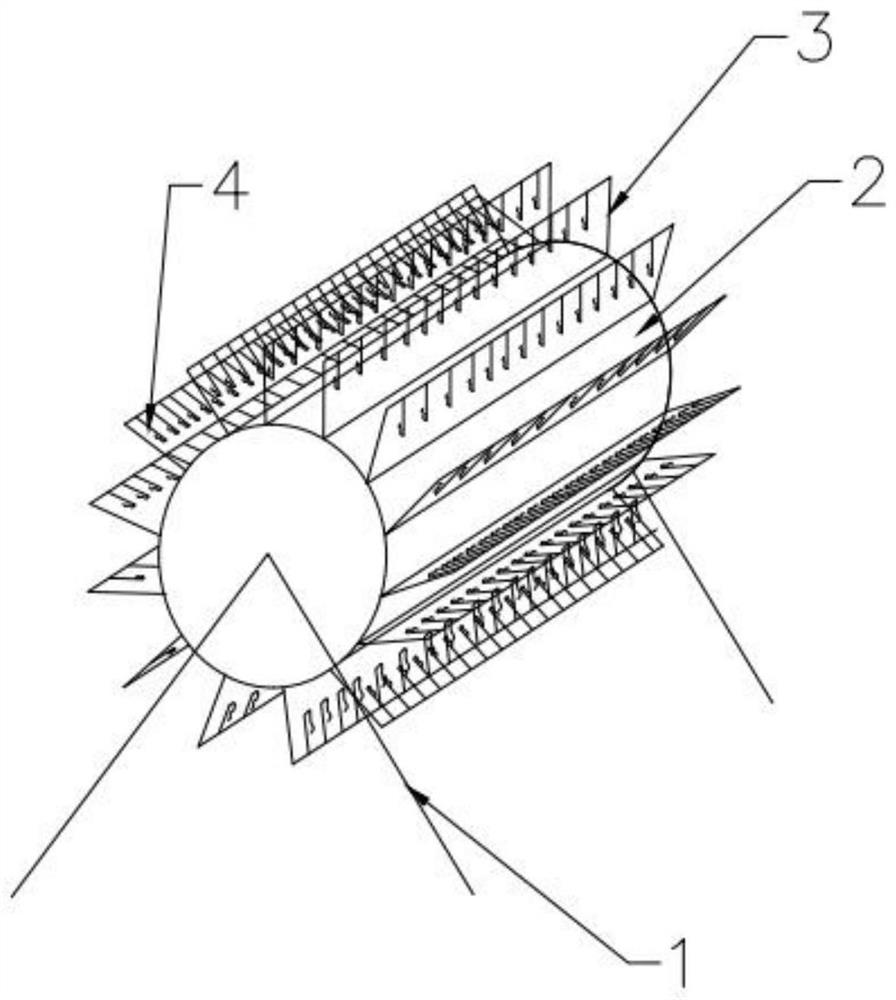

[0041] A kind of dried noni fruit processing technology provided by the present embodiment, as a further improvement to embodiment 1, comprises the following steps:

[0042] 101. Select ripe, mold-free, and pest-free noni fruits for cleaning, and pick noni fruits with a maturity of more than 90% from the orchard for picking, and avoid picking noni fruits with a maturity of less than 90% that taste bitter. The post-processing of the dried fruit will have a certain impact on the taste of the dried fruit. After picking, the Noni fruit with a suitable size, good appearance, no damage, and no pests is selected;

[0043] 102. Slice the cleaned Noni fruit between 5:00-8:00 p.m., preferably at 6:00 p.m., and take it out to dry at 6:00 or 7:00 the next morning after slicing at 6:00 p.m. The drying time is shortened, and the drying speed is accelerated. The thickness of the slice is 2mm-4mm, preferably 3mm. If it is too thick, it will affect the drying time. If it is too thin, it will no...

Embodiment 3

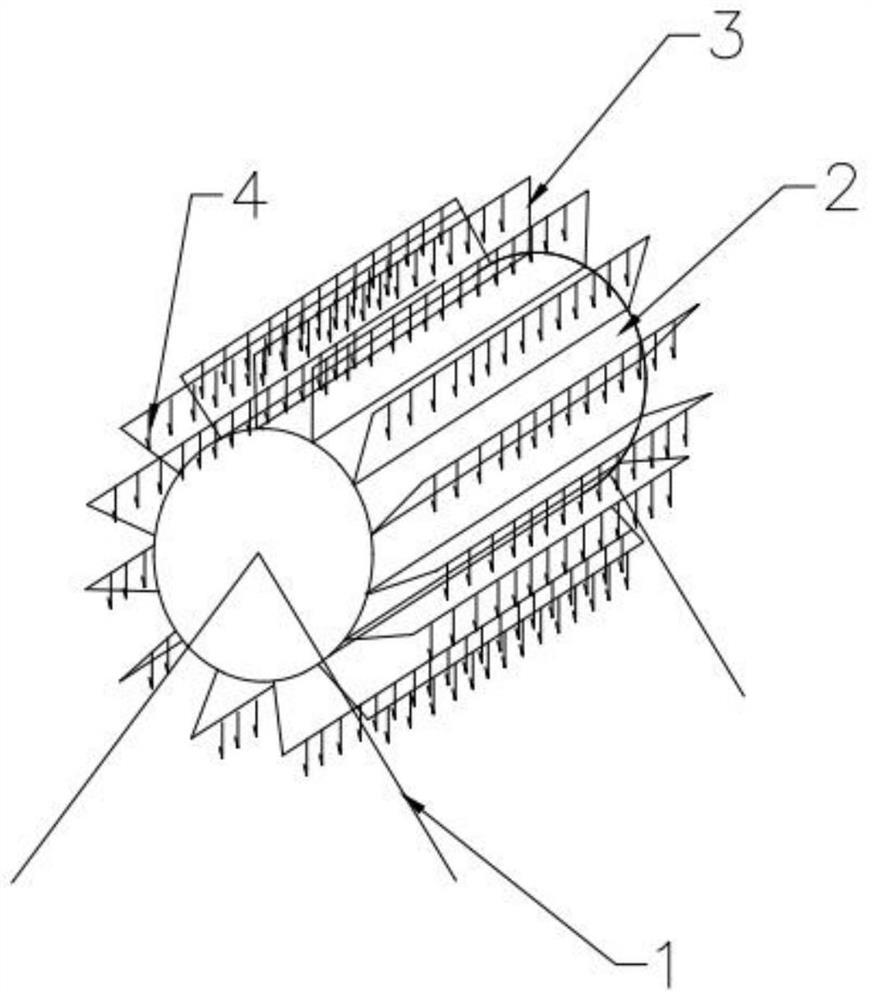

[0051] A kind of noni dried fruit processing technology provided by the present embodiment, as a further improvement to the drying device in embodiment 2, comprises the following steps:

[0052] 101. Select ripe, mold-free, and pest-free noni fruits for cleaning, and pick noni fruits with a maturity of more than 90% from the orchard for picking, and avoid picking noni fruits with a maturity of less than 90% that taste bitter. The post-processing of the dried fruit will have a certain impact on the taste of the dried fruit. After picking, the Noni fruit with a suitable size, good appearance, no damage, and no pests is selected;

[0053] 102. Slice the cleaned Noni fruit between 5:00-8:00 p.m., preferably at 6:00 p.m., and take it out to dry at 6:00 or 7:00 the next morning after slicing at 6:00 p.m. The drying time is shortened, and the drying speed is accelerated. The thickness of the slice is 2mm-4mm, preferably 3mm. If it is too thick, it will affect the drying time. If it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com