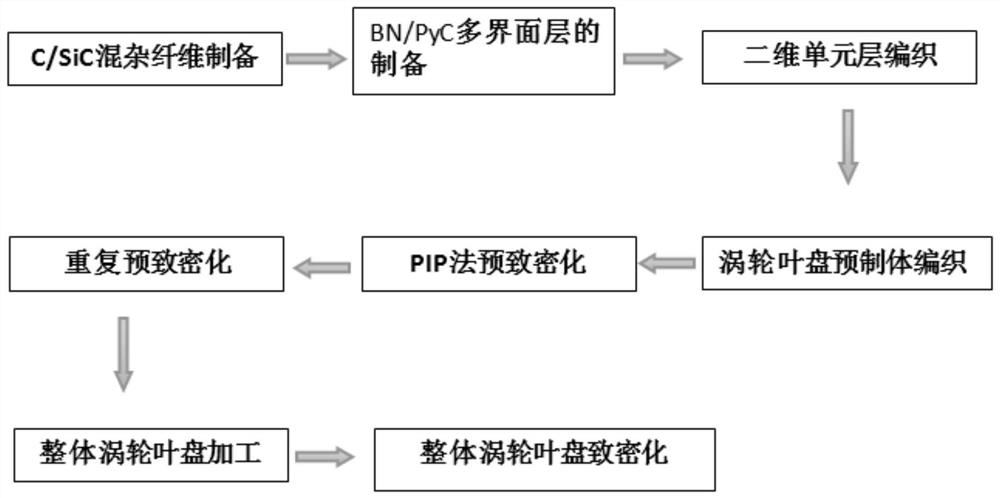

Preparation method of monolithic turbine blade disc based on continuous carbon/silicon carbide fiber hybrid reinforced ceramic matrix composite material

A technology of silicon carbide fiber and turbine blisk, which is applied to the supporting elements of blades, mechanical equipment, machines/engines, etc., can solve problems such as poor practicability, achieve high-density preparation, improve low-temperature and high-temperature bearing performance, and shorten the preparation period. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Step 1. Preparation of continuous C / SiC hybrid fibers mixed between bundles

[0034] First, install a bunch of 1K T300 carbon fiber and 1K silicon carbide fiber on the spinning frame respectively, the ratio of carbon fiber to silicon carbide is 20:80; they pass through the high temperature furnace at the same time, and the high temperature furnace adopts flowing inert gas (such as N 2 Gas, etc.) protection, the gas flow rate is 70L / min, the temperature in the furnace is 400°C,

[0035] Secondly, two bundles of C / SiC fibers are jointed at the furnace mouth of the high-temperature furnace, and then sizing is sequentially passed through the sizing tank. The sizing agent is 2% polyvinyl alcohol aqueous solution, and the water is deionized water;

[0036] Thirdly, the continuous C / SiC hybrid fiber after ply sizing is dried through a dryer in sequence, and the temperature of the dryer is 110°C;

[0037] Finally, a fiber winding machine is used to wind up the fibers to obtain...

Embodiment 2

[0058] Step 1. Preparation of continuous C / SiC hybrid fibers mixed between bundles

[0059] First, install a bunch of 3K T300 carbon fiber and 0.5K silicon carbide fiber on the spinning frame respectively, the ratio of carbon fiber to silicon carbide is 50:50; they pass through the high temperature furnace at the same time, and the high temperature furnace adopts flowing inert gas (such as N2 gas, etc.) protection, the gas flow rate is 70L / min, and the furnace temperature is 500°C.

[0060] Secondly, two bundles of C / SiC fibers are jointed at the furnace mouth of the high-temperature furnace, and then sizing through the sizing tank in turn. The sizing agent is 4% polyvinyl alcohol aqueous solution, and the water is deionized water;

[0061] Thirdly, the continuous C / SiC hybrid fiber after ply sizing is dried through the dryer in sequence, and the dryer adopts flowing high-temperature air to dry, and the temperature of the dryer is 200°C;

[0062] Finally, a fiber winding mach...

Embodiment 3

[0083] Step 1. Preparation of continuous C / SiC hybrid fibers mixed between bundles

[0084] First, install a bundle of 1K T800 carbon fiber and 0.6K silicon carbide fiber on the spinning frame, and pass them through the high-temperature furnace at the same time. The high-temperature furnace adopts flowing inert gas (such as N 2 Gas, etc.) protection, the gas flow rate is 70L / min, the furnace temperature is 600°C; the ratio of carbon fiber to silicon carbide is 40:60.

[0085] Secondly, two bundles of C / SiC fibers are jointed at the furnace mouth of the high-temperature furnace, and then sizing through the sizing tank in turn. The sizing agent is 5% polyvinyl alcohol aqueous solution, and the water is deionized water;

[0086] Thirdly, the continuous C / SiC hybrid fiber after ply sizing is dried through the dryer in sequence, and the dryer adopts flowing high-temperature air to dry, and the temperature of the dryer is 300°C;

[0087] Finally, a fiber winding machine is used to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com