Nanometer fluorination catalyst for preparing R152a and preparation method of nanometer fluorination catalyst

A fluorination catalyst, nano technology, applied in the field of nano fluorination catalyst and its preparation, can solve the problem of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

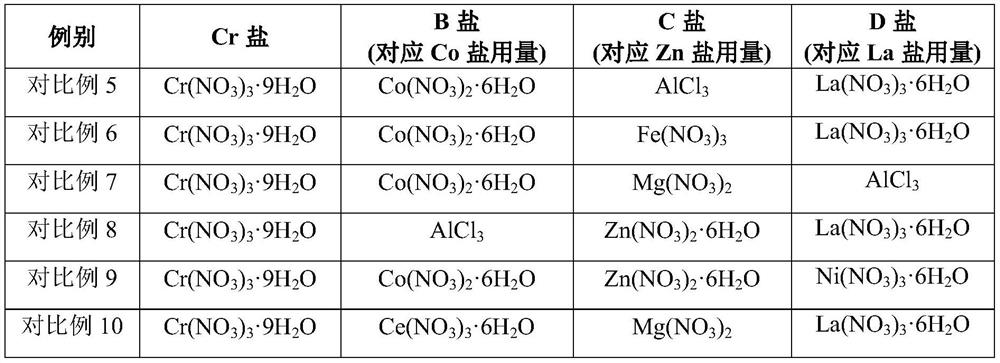

Examples

Embodiment 1

[0046] Add 0.1mol Cr(NO 3 ) 3 9H 2 O, 0.012mol Co(NO 3 ) 2 ·6H 2 O, 0.008mol Zn(NO 3 ) 2 ·6H 2 O and 0.030mol La(NO 3 ) 3 ·6H 2 O, and add 0.0008mol of PEG4000 and 0.0002mol of cetyltrimethylammonium bromide, stir and dissolve to obtain a mixed salt solution.

[0047] Add 100g of 0.5mol / L EDTA aqueous solution and 4.5g of 25% ammonia water dropwise while stirring at 40°C to form a gel, age at room temperature for 4 hours, filter to remove the clear liquid, wash with water twice, and spray dry. Set the inlet temperature to 200°C, the outlet temperature to 100°C, and the air flow to 5m 3 / h.

[0048] Calcining the spray-dried mixture at 550° C. for 2 hours to obtain a mixed nano-powder, adding 1% graphite, mixing evenly, and pressing into tablets to obtain a nano-fluorination catalyst precursor.

[0049] According to the transmission electron microscope photos, the crystal grain size of the obtained mixed nano powder is 25-40nm, with less agglomeration and good disp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com