Method for removing sulfide corrosion layer on surface of blade by arc spot plasmas

A sulfide corrosion and plasma technology, used in design optimization/simulation, special data processing applications, etc., can solve the problems of non-reusable parameters, lack of data support, difficult operation, etc., to achieve strong practicability, large workload, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following implementation process will further illustrate the present invention in order to better illustrate the advantages and characteristics of the present invention.

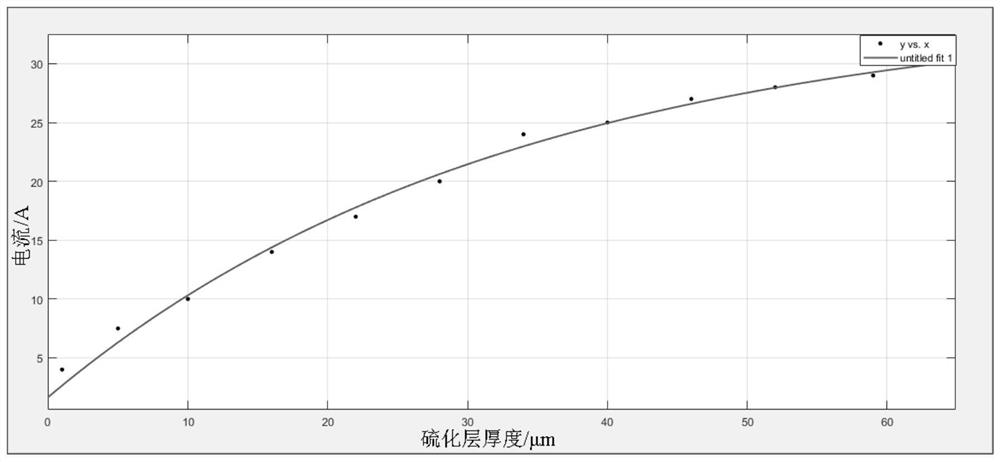

[0028] The purpose of the present invention is to provide a clean, efficient and practical method for removing the sulfide corrosion layer on the surface of the compressor blade of the helicopter engine. In order to achieve the above goals, the method for determining the removal parameters of the arc spot plasma device is as follows:

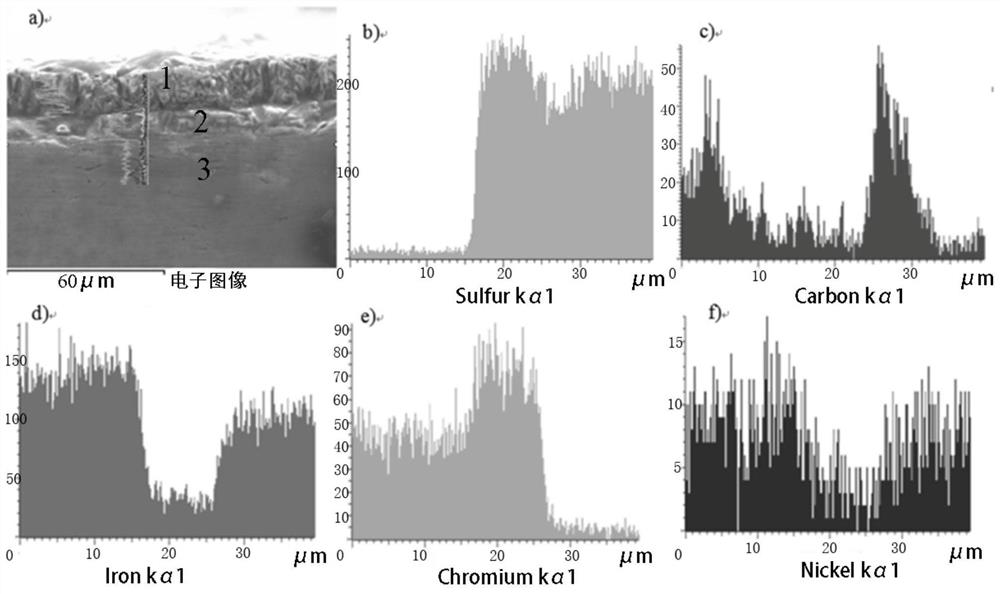

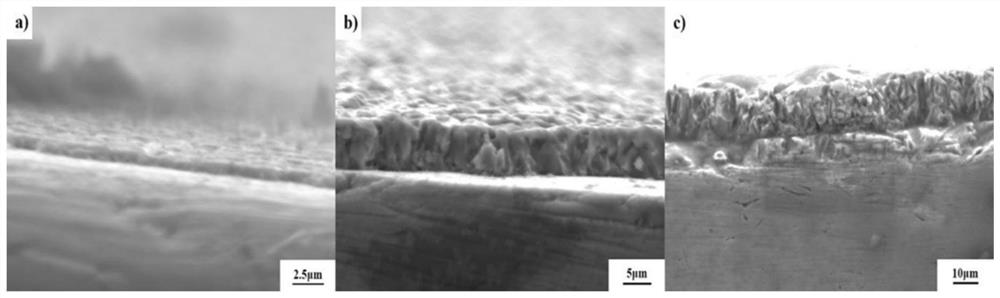

[0029] 1. Measure the surface vulcanized layer thickness d from the helicopter engine compressor blade containing the sulfide corrosion layer; the measurement method of the vulcanized layer thickness d can be adopted: take the section perpendicular to the vulcanized layer as the detection surface, use scanning electron microscope or metallographic The microscope measures the thickness of the cross-section of the sulfide corrosion layer through the calibrated scale; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com