Automatic punching machine for radial hole of thin-wall annular part

A technology of circular parts and radial holes, which is applied in the field of automatic punching machines for radial holes of thin-walled circular parts, can solve the problems of low production efficiency, stamping radial holes, and high labor intensity, and achieve high production efficiency and good processing quality , the effect of low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

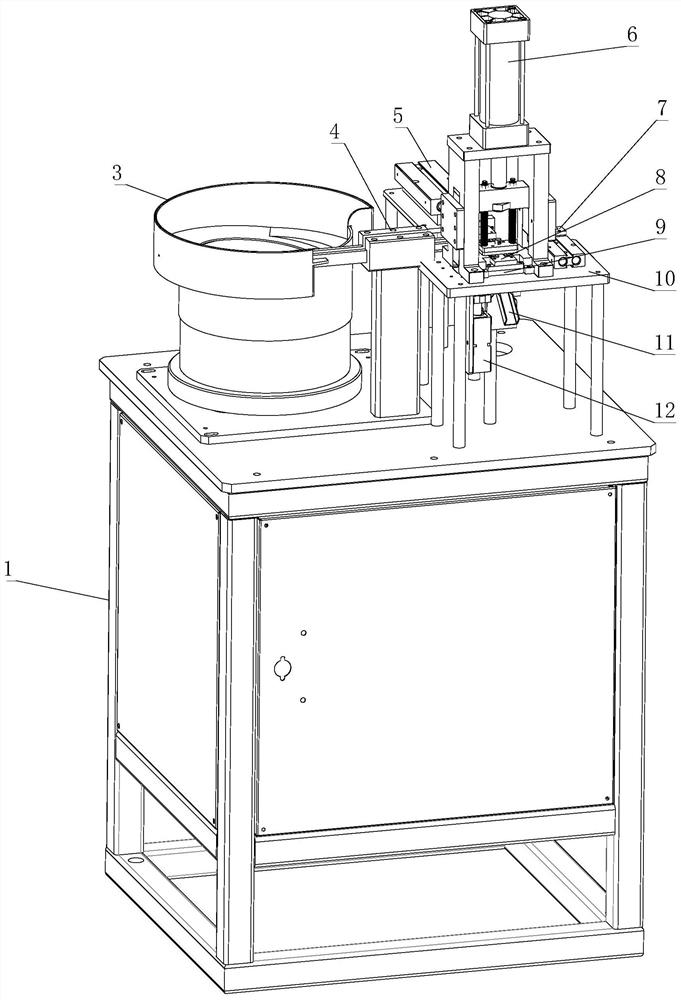

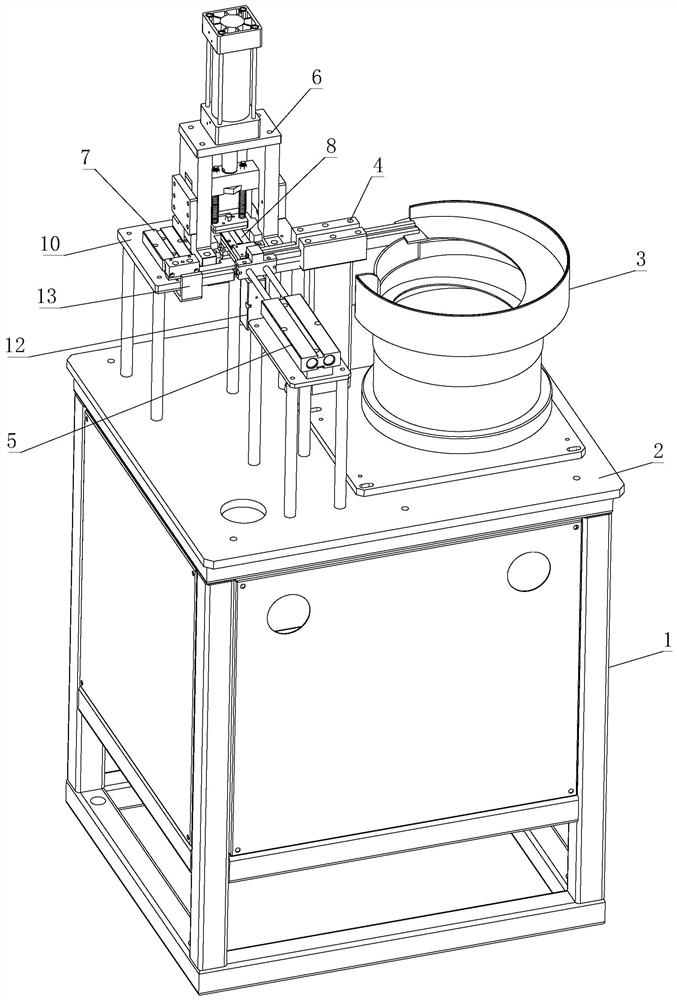

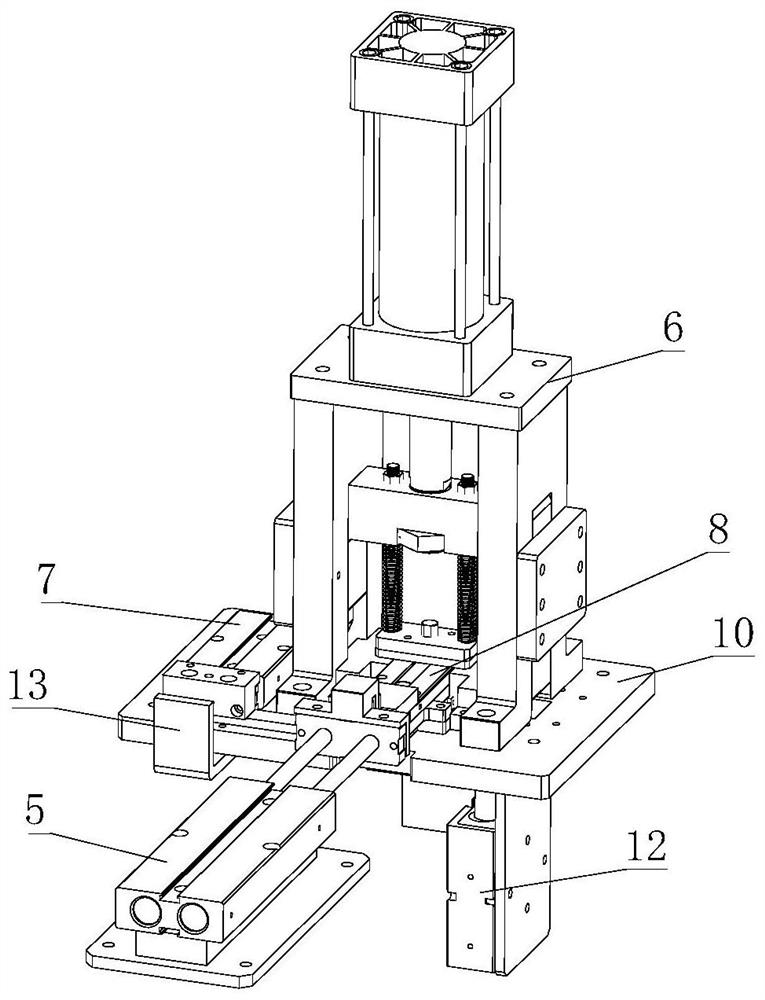

[0038] Such as Figure 1 to Figure 15 As shown, an automatic punching machine for radial holes of thin-walled annular parts according to the present invention includes a workbench 1 and a fixed plate 10, and a feeding assembly and a pusher assembly 5 are installed on the workbench 1, and the fixed plate 10 is located above the workbench 1, the drive part 6 is installed on the fixed plate 10, the backing plate 9 is installed on the inner side of the drive part 6 on the fixed plate 10, and the material guide assembly is installed on the backing plate 9 8. The feed port of the material guide assembly 8 is connected to the discharge port of the feed assembly, the material return assembly 7 and the punch assembly 15 are installed on the fixed plate 10, and the bottom of the fixed plate 10 is equipped with a concave Die assembly 12 . I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com