Mn-modified Cu-SSZ-13 catalyst as well as preparation method and application thereof

A cu-ssz-13, catalyst technology, applied in the direction of catalyst activation/preparation, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of insufficient mechanical strength, difficult catalyst molding, etc., to achieve improved dispersion, easy operation, and optimization distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

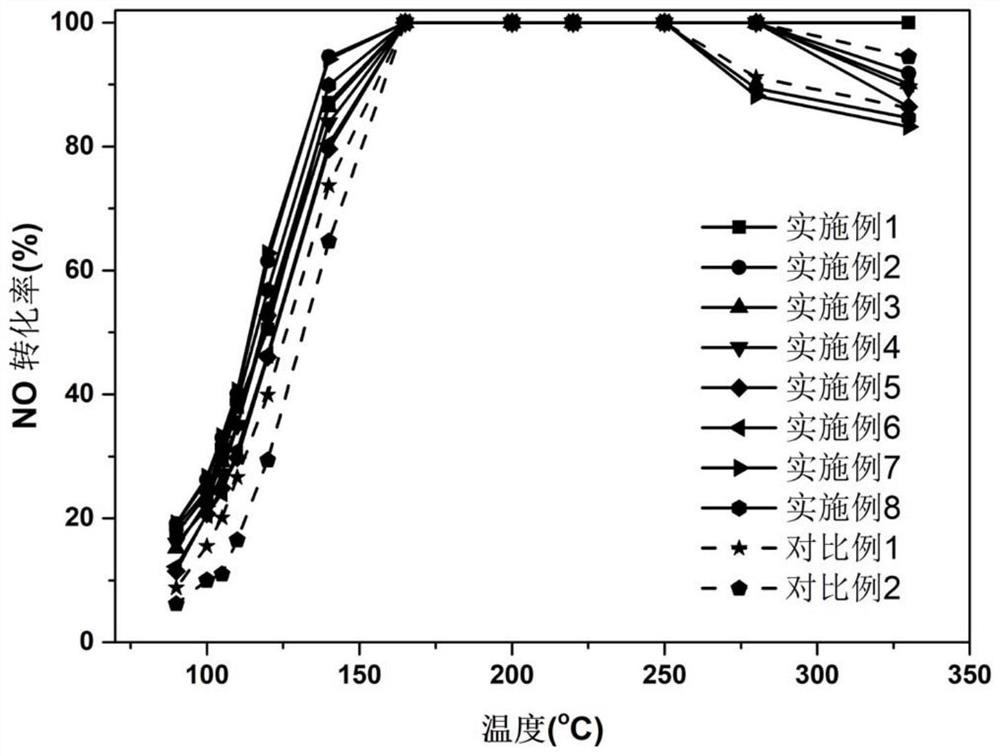

Examples

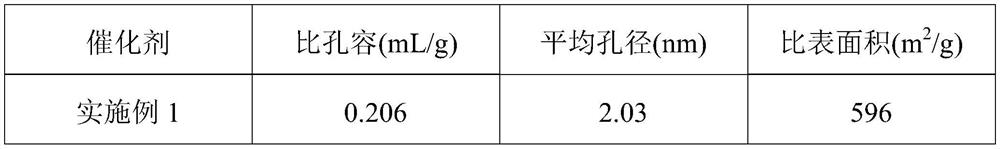

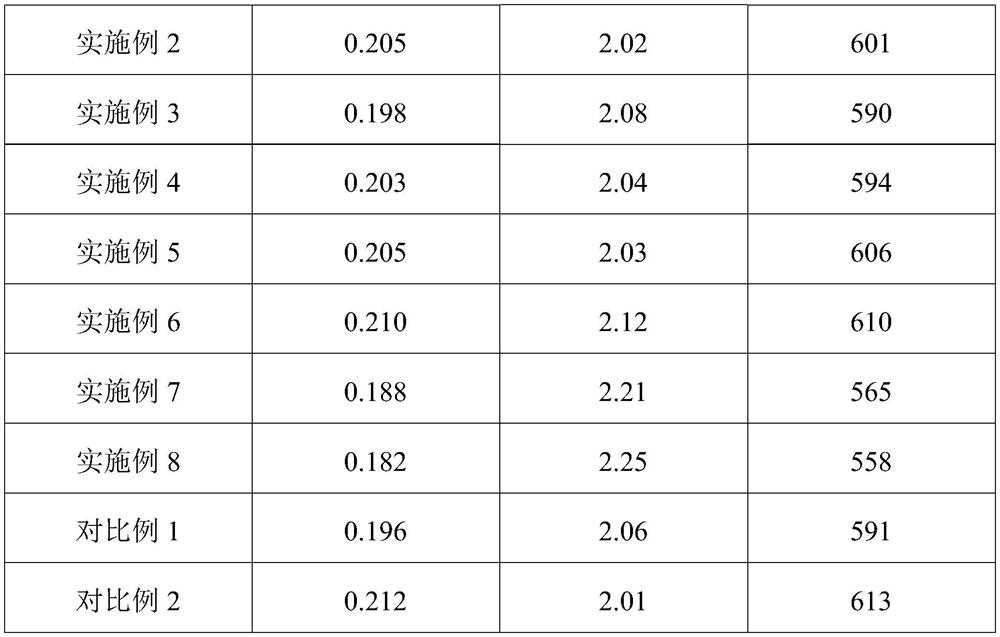

Embodiment 1

[0053] This embodiment provides a kind of Mn modified Cu-SSZ-13 catalyst and its preparation method, and the preparation method comprises the following steps:

[0054] (1) Using H + Concentration is the nitric acid solution pickling Cu-SSZ-13 catalyst of 0.25mol / L, obtains pretreatment Cu-SSZ-13 catalyst after suction filtration, washing, drying, roasting; The liquid-solid ratio of described pickling is 50mL / g , the temperature is 70°C, and the time is 12h; the washing liquid used in the washing is deionized water; the temperature of the drying is 80°C, and the time is 12h; the roasting is carried out under an air atmosphere, and the temperature is 600°C, The heating rate was 8°C / min, and the time was 6h; the Cu-SSZ-13 catalyst was a molecular sieve prepared by the preparation method disclosed in Example 1 of CN 101973562A, and was calcined in a muffle furnace at 600°C for 6h.

[0055] (2) Utilize the manganese acetate solution to vacuum impregnate the Cu-SSZ-13 catalyst obta...

Embodiment 2

[0058] This embodiment provides a kind of Mn modified Cu-SSZ-13 catalyst and its preparation method, and the preparation method comprises the following steps:

[0059] (1) Using H + Concentration is the sulfuric acid solution acid leaching Cu-SSZ-13 catalyst of 0.15mol / L, obtains pretreatment Cu-SSZ-13 catalyst after filtering, washing, drying, roasting; The liquid-solid ratio of described acid leaching is 30mL / g, The temperature is 60°C, and the time is 14h; the washing liquid used in the washing is absolute ethanol; the temperature of the drying is 70°C, and the time is 14h; the roasting is carried out under the air atmosphere, the temperature is 550°C, The rate is 6°C / min, and the time is 7h; the Cu-SSZ-13 catalyst is a molecular sieve prepared by the preparation method disclosed in Example 1 of CN 101973562A, and is calcined in a muffle furnace at 600°C for 6h.

[0060] (2) Utilize the manganese nitrate solution to vacuum impregnate the Cu-SSZ-13 catalyst obtained in step...

Embodiment 3

[0063] This embodiment provides a kind of Mn modified Cu-SSZ-13 catalyst and its preparation method, and the preparation method comprises the following steps:

[0064] (1) Using H +Concentration is the hydrochloric acid solution acid leaching Cu-SSZ-13 catalyst of 0.38mol / L, obtains pretreatment Cu-SSZ-13 catalyst after centrifugation, washing, drying, roasting; The liquid-solid ratio of described acid leaching is 75mL / g, The temperature is 80°C, and the time is 10h; the washing liquid used in the washing is deionized water; the temperature of the drying is 90°C, and the time is 10h; The rate was 12°C / min, and the time was 5h; the Cu-SSZ-13 catalyst was a molecular sieve prepared by the preparation method disclosed in Example 1 of CN 101973562A, and was calcined in a muffle furnace at 600°C for 6h.

[0065] (2) Utilize the manganese chloride solution to vacuum impregnate the Cu-SSZ-13 catalyst obtained in step (1) in a rotary evaporator until the catalyst is completely dry, d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com