Tail gas treater of storage battery car

A tail gas treatment and battery car technology, applied in electrical components, electrochemical generators, circuits, etc., can solve the problems of inflexible use, slow exhaust gas discharge speed, low purification efficiency, etc., achieve flexible use, improve rotation effect, and enhance cleaning effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be described clearly and completely in conjunction with the accompanying drawings in the embodiments of the present invention.

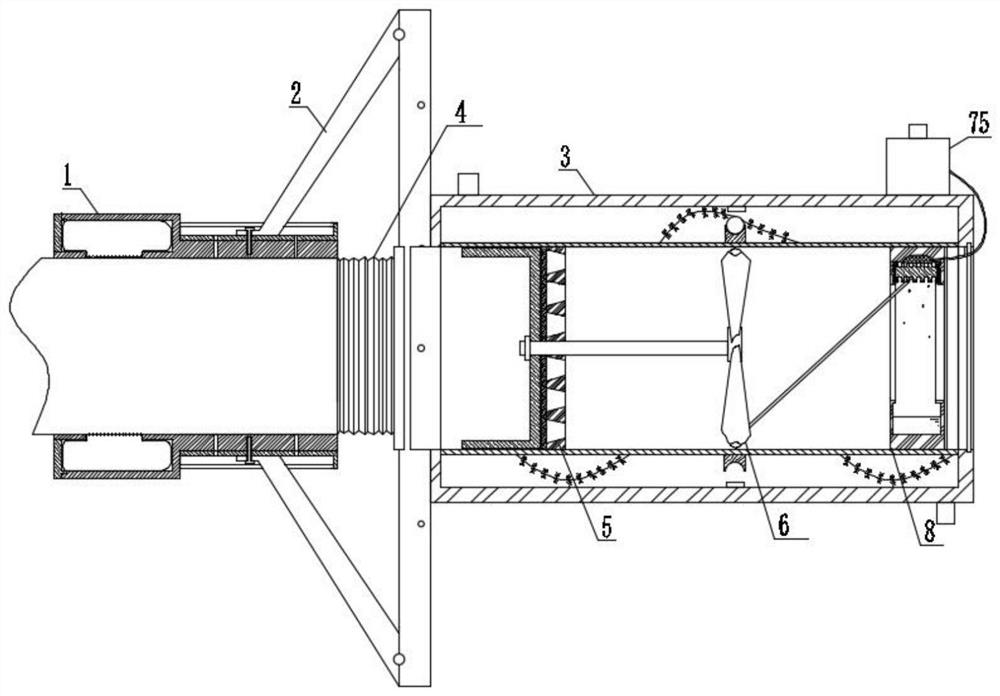

[0032]Such asFigure 1-10 As shown, an exhaust gas processor for a battery car includes a fixing device 1, a height adjustment device 2 and an exhaust gas processing device 3. Wherein, the fixing device 1 is connected to the air outlet end 100 of the exhaust pipe of the battery car, and the exhaust pipe of the battery car has an existing structure and will not be repeated here. The height adjustment device 2 is connected to the fixing device 1, and the exhaust gas treatment device 3 is connected to the height adjustment device 2 by lifting.

[0033]Specifically, the exhaust gas treatment device 3 has an air inlet and an air outlet, wherein the air inlet is connected to the outlet en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com