Vegetable meat sausage and preparation method thereof

A production method and plant technology, applied in the fields of food science, vegetarian ingredients (meat-free), food ingredients as emulsifiers, etc., can solve the problems of not moisturizing the mouth, dry and hard product texture, and great differences.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

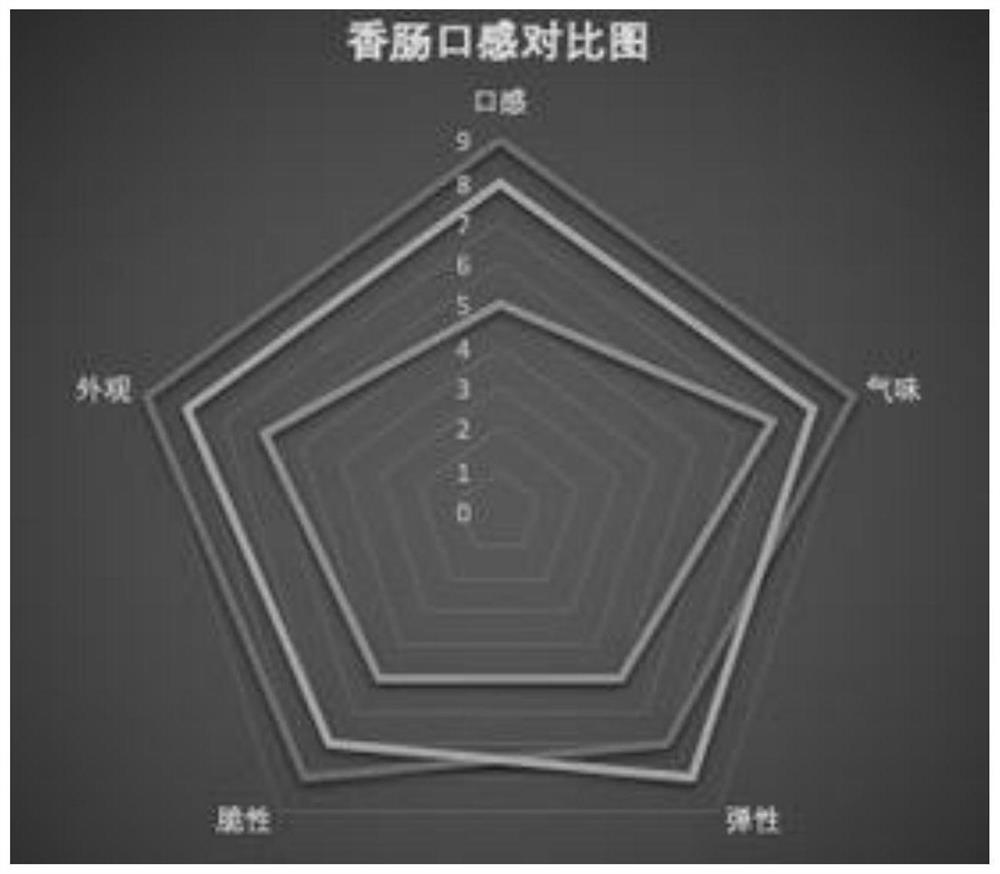

Image

Examples

Embodiment 1

[0029] A plant meat sausage, the raw materials include 15-40% of vegetable protein, 10-20% of vegetable oil, 1-5% of water-soluble colloid, 1-10% of starch, 0.2-5% of emulsifier, and flour products in parts by weight. Improver 0.1-1%, seasoning and essence 1-10%, and the rest is ice water.

[0030] The invention makes full use of the unique characteristics of wheat protein, such as elasticity, extensibility and ability to form a network structure. At the same time, colloids and emulsifiers are used to supplement the problems of insufficient emulsification of wheat protein and poor oil retention effect. Use the improver to stabilize and improve the formed system to obtain a controllable and suitable taste, and then use seasonings and essences to improve the aroma and taste of the product, so as to obtain a perfect vegetable meat product.

[0031] Wherein said vegetable protein is wheat protein;

[0032] The vegetable oil mentioned therein is soybean oil, salad oil, sunflower ...

Embodiment 2

[0047] Example 2 Original Vegetarian Sausage

[0048] raw material:

[0049] Wheat protein 25%, salad oil 15%, ice water 46.6%, sodium caseinate 0.8%, acetylated distarch phosphate 3%, sodium alginate 2%, ascorbic acid 0.1%

[0050] seasoning:

[0051] Salt 1.2%, Sugar 2%, Original Sausage Seasoning 4.3%

[0052] Process:

[0053] 1 Add the emulsified salad oil and ice water to the chopping machine, turn on the chopping and mixing to high speed, slowly add wheat protein, soybean protein, sodium caseinate, acetylated distarch phosphate, sodium alginate and sodium ascorbate, and chop until After the filling is thick, turn to low speed and mix;

[0054] Then add the seasoning, chop and mix at a low speed for about 5 minutes, until the filling no longer sticks to the chopping pot, stop;

[0055] 2 Refrigerate and let the stuffing transfer to a 4-10 degree refrigerator for 2 hours;

[0056] 3 Filling Use a vacuum sausage filling machine and plastic casings for filling.

[00...

Embodiment 3

[0061] raw material:

[0062]Wheat protein 35%, salad oil 20%, ice water 36.7%, sodium caseinate 2%, potato starch 5%, sodium alginate 1%, L-cysteine hydrochloride 0.2%, ascorbic acid 0.1%

[0063] seasoning:

[0064] Salt 1.4%, Sugar 4%, Plain Sausage Seasoning 4.3%

[0065] Process:

[0066] 1 Add the emulsified salad oil and ice water to the chopping machine, turn on the chopping to high speed, slowly add wheat protein, sodium caseinate, starch, sodium alginate, ascorbic acid, L-cysteine hydrochloride, and chop When the filling is thick, turn to low speed and mix;

[0067] Then add the seasoning, chop and mix at a low speed for about 5 minutes, until the filling no longer sticks to the chopping pot, stop;

[0068] 2 Refrigerate and let the stuffing transfer to a 4-10 degree refrigerator for 2 hours;

[0069] 3 Filling Use a vacuum sausage filling machine and plastic casings for filling.

[0070] 4. The matured and filled sausages are directly sterilized in a high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com