Adhesive layer slurry preparation material, preparation method and gas sensor

A bonding layer, slurry technology, applied in the analysis of materials, material analysis by electromagnetic means, conductive materials dispersed in non-conductive inorganic materials, etc., can solve the problem of poor bonding strength, ceramic core cracking, gas The problem of poor tightness, etc., can improve the air tightness, reduce the sintering temperature, and match the shrinkage rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

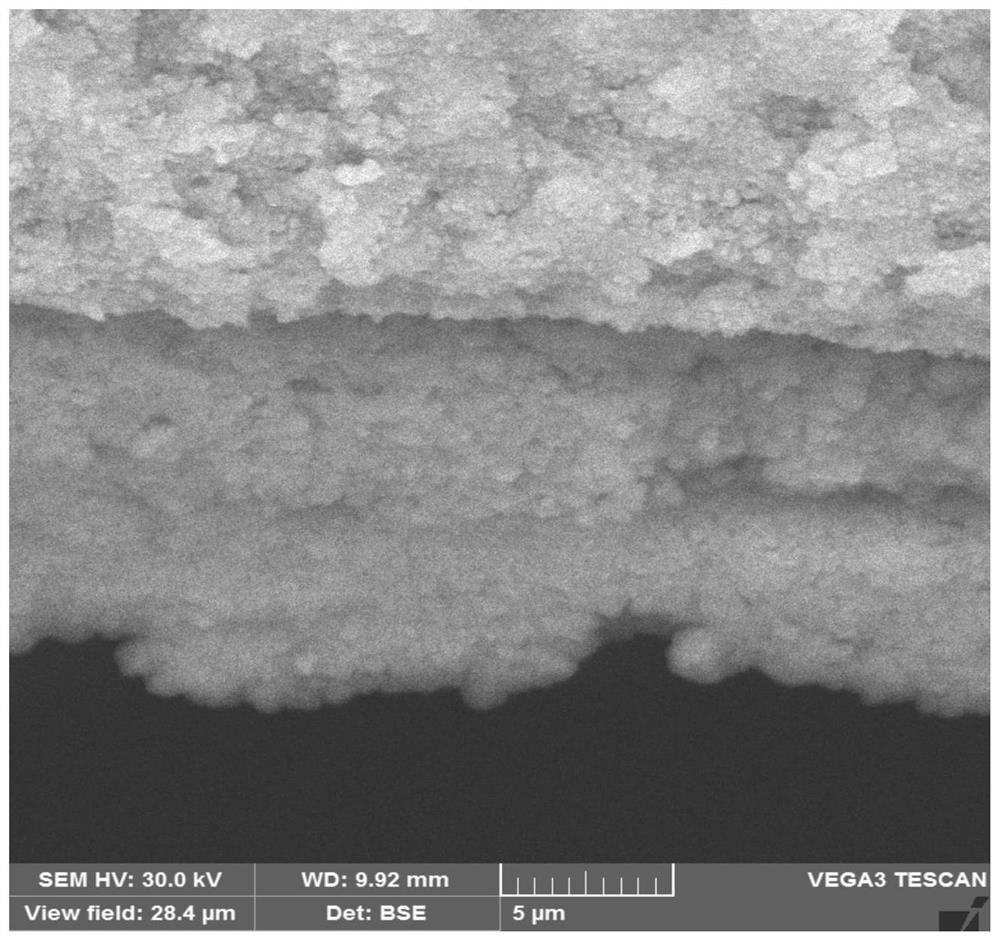

Image

Examples

preparation example Construction

[0053] The embodiment of the present invention also provides a method for preparing adhesive layer slurry using the adhesive layer slurry preparation material, comprising the following steps:

[0054] ball milling the zirconia powder, the yttrium oxide powder, the inorganic additive, the organic solvent, and the organic additive for 12 to 36 hours to obtain a mixture;

[0055] Adding the organic vehicle and the organic additive to the mixture, and continuing ball milling for 12 to 36 hours to obtain a pre-slurry;

[0056] Filter the pre-slurry through a 100-400-mesh filter, adjust the viscosity and let it stand for at least 1 hour to obtain the adhesive layer slurry.

Embodiment 1

[0063] In this embodiment, the preparation material of the adhesive layer slurry contains the following components in mass percent:

[0064] Zirconia powder: 56.51%, D50: 0.5987μm;

[0065] Yttrium oxide powder: 2.77%, D50: 0.1624μm;

[0066] Inorganic additives: 1.52% Al 2 o 3 ~SiO2 2 , where the mass ratio of Al 2 o 3 : SiO 2 :=2:1;

[0067] Organic solvent: 32.39% mixture of terpineol, butyl glycol ether and dimethylacetamide, wherein the mass ratio of terpineol: butyl glycol ether: dimethylacetamide = 3:1:2;

[0068] Organic vehicle: 3.62% ethyl cellulose;

[0069] Organic additives: 0.64% dispersant (silane coupling agent), 1.55% plasticizer (a mixture of dibutyl phthalate and triethylene glycol diisocaprylate), 0.5% defoamer ( foam breaking polymer and polysiloxane solution), 0.5% thixotropic agent (modified urea solution).

[0070] The method steps for preparing the adhesive layer slurry and the adhesive layer by using the above materials are as follows:

[0...

Embodiment 2

[0076] In this embodiment, the preparation material of the adhesive layer slurry contains the following components in mass percent:

[0077] Zirconia powder: 53.37%, D50: 0.6491μm;

[0078] Yttrium oxide powder: 4.1%, D50: 0.1624μm;

[0079] Inorganic additives: 2.72% Al 2 o 3 ~SiO2 2 ~MgO~CaO, the mass ratio of Al 2 o 3 : SiO 2 :MgO:CaO=29:21:2:1;

[0080] Organic solvent: 29.57% mixture of terpineol, isobutanol and propyl acetate, wherein the mass ratio of terpineol:isobutanol:propyl acetate=5:1:1;

[0081] Organic carrier: 5.37% mixture of polyvinyl butyral and ethyl cellulose, wherein the mass ratio of polyvinyl butyral: ethyl cellulose = 1:1;

[0082] Organic additives: 0.92% dispersant (polyester copolymer), 2.15% plasticizer (a mixture of dibutyl phthalate and triethylene glycol diisocaprylate), 0.6% thixotropic agent ( modified urea solution), 0.8% leveling agent (polyether modified methyl alkyl polysiloxane copolymer), 0.4% lubricant (polyethylene glycol).

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com