Heat exchanger capable of automatically defrosting or deicing

A heat exchanger, automatic technology, applied in the direction of heat exchanger shell, heat exchange equipment, lighting and heating equipment, etc., can solve the problems of long liquefaction time, large loss of cooling capacity during transmission, etc., to improve heat exchange efficiency and improve refrigeration Efficiency, the effect of improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

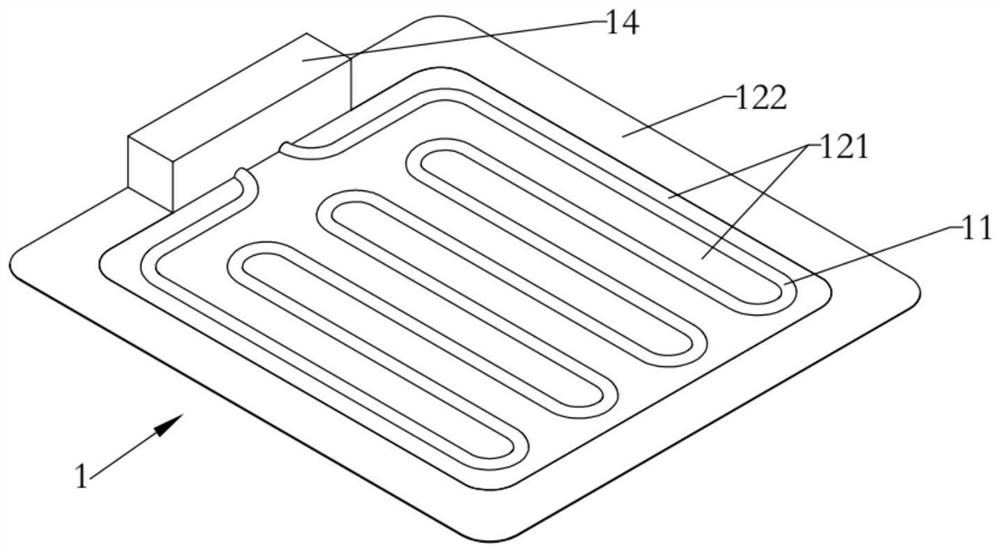

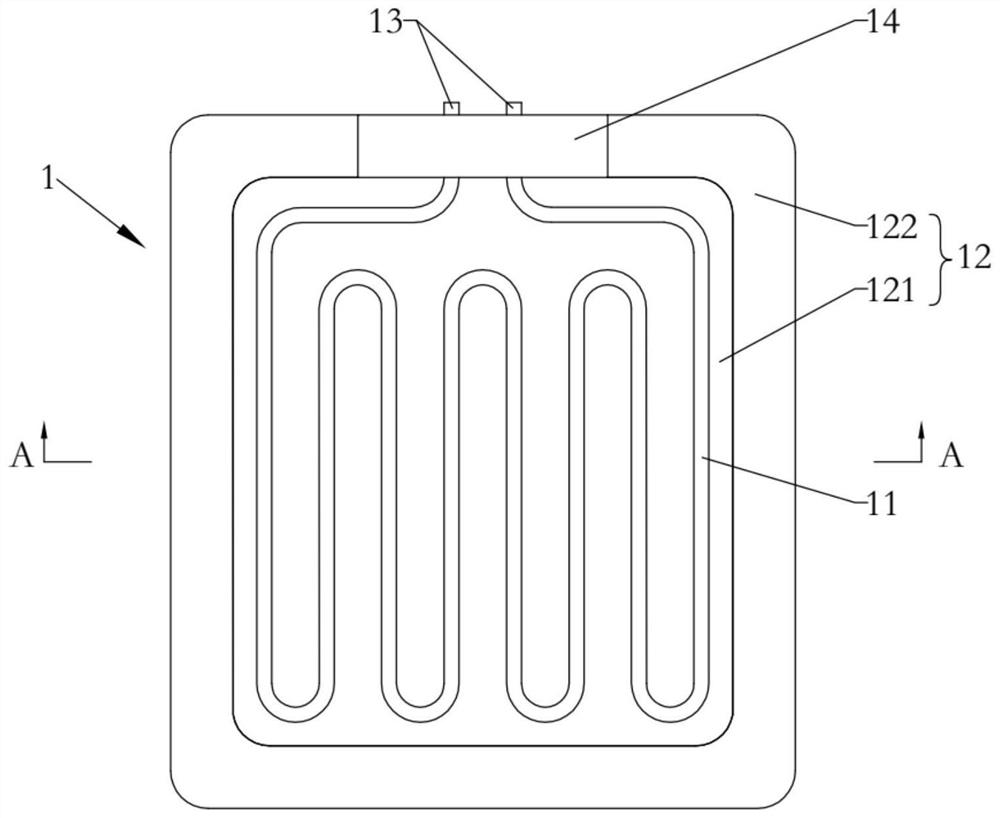

[0039] Such as Figure 1-Figure 4 As shown, this embodiment provides a heat exchanger 1 capable of automatic defrosting or deicing, including coiled tubes 11 and finned plates 12 . Wherein, the brine can be passed into the coil tube 11, and the coil tube 11 is coiled in the same plane. The finned plate 12 includes a first finned plate 121 and a second finned plate 122, the first finned plate 121 is connected to the coiled tube 11 and surrounds the coiled tube 11, the first finned plate 121 and the coiled tube 11 are on the same plane Inside, the second finned plate 122 surrounds the first finned plate 121 and is spliced with the first finned plate 121 in the same plane. The thermal conductivity of the second finned plate 122 is smaller than the thermal conductivity of the first finned plate 121 and the thermal conductivity of the coil 11 . Both the surface of the first fin plate 121 and the surface of the coiled pipe 11 are coated with a micron or nanoscale hydrophobic lay...

Embodiment 2

[0058] Such as Figure 5 As shown, this embodiment provides another heat exchanger 1 , the difference between the heat exchanger 1 provided by this embodiment and the first embodiment is that an upper insulation layer 16 is added on the basis of the first embodiment. Specifically, the heat exchanger 1 also includes an upper thermal insulation layer 16, which covers the upper surface of the coil tube 11 and the finned plate 12, and the thermal conductivity of the upper thermal insulation layer 16 is smaller than that of the coiled tube 11 and the first finned plate. 121 thermal conductivity. It should be pointed out that since the upper thermal insulation layer 16 covers the upper surface of the coiled tube 11 and the finned plate 12, it is only necessary to cover the lower surface of the coiled tube 11 and the first finned plate 121 with the hydrophobic layer 15 at this time.

[0059] When the heat exchanger 1 is placed vertically, that is, when the plate surface of the heat ...

Embodiment 3

[0061] For more controllable and easier removal of ice or frost layers from heat exchanger surfaces, it can be done in conjunction with a heat source. Such as Figure 6 As shown, this embodiment provides a controllable automatic defrosting or deicing heat exchanger system, based on the heat exchanger 1 provided in Embodiment 2, this system can be applied in refrigeration equipment such as refrigerators or freezers. The controllable automatic defrosting or deicing heat exchanger system provided in this embodiment includes a heat exchanger 1 , a switching valve 2 , and a low-temperature cold source and a high-temperature heat source 3 . The low-temperature cold source and the high-temperature heat source 3 are connected to the coil pipe 11 through the switch valve 2, so as to feed the brine or heat transfer agent into the coil pipe 11. Specifically, in this embodiment, the switching valve 2 is a four-way valve. In the deicing working condition, the low-temperature cooling sour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com