Rotational flow torch igniter based on 3D printing forming

A torch igniter, 3D printing technology, applied in the direction of combustion method, combustion chamber, combustion equipment, etc., can solve the problems of difficult to realize miniaturization design, easy ablation of spark plug tip, narrow adaptability to variable working conditions, etc. Effects of thermal protection problems, prolonging gas residence time, shortening body length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

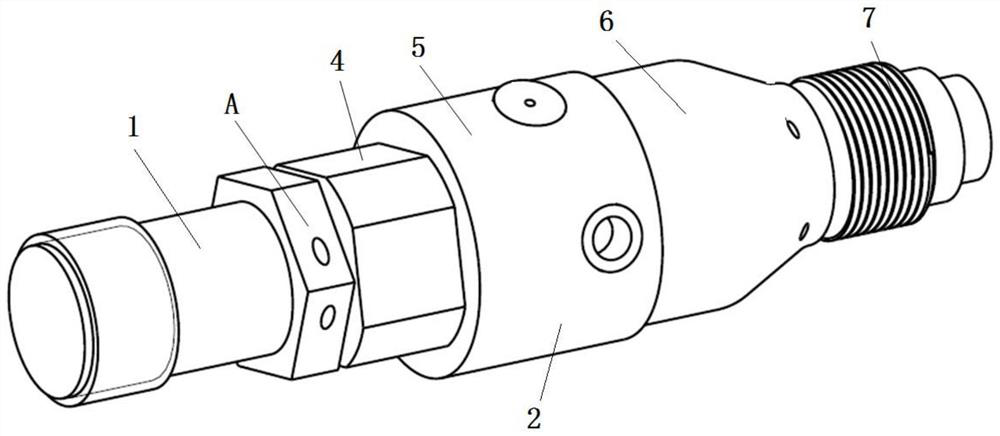

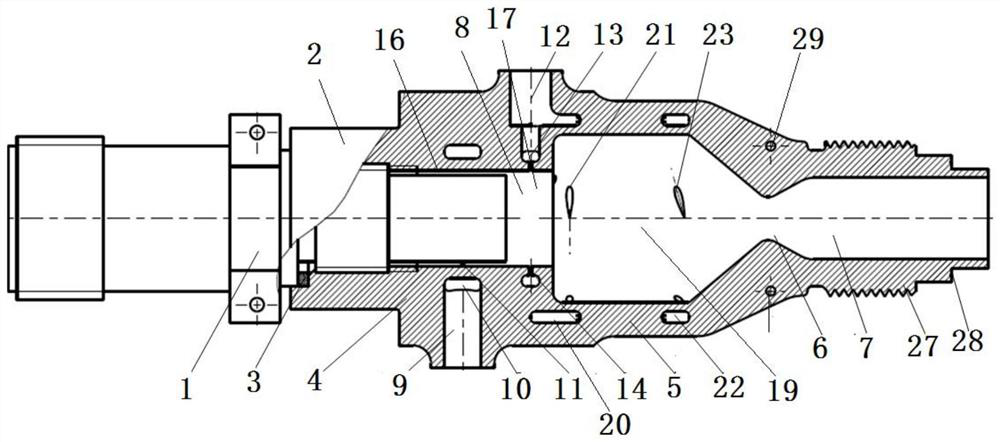

[0049] Such as figure 1 , figure 2 As shown, the basic structure of the 3D printing-based swirl torch igniter of the present invention includes an electric spark plug rod 1, a torch ignition tube 2 and a copper sealing gasket 3;

[0050] The spark plug rod 1 and the torch ignition tube 2 are connected through threads, and rely on the copper sealing gasket 3 to realize high-pressure sealing;

[0051] The torch ignition tube 2 includes a head section 4, a body section 5, a throat nozzle section 6 and a tail section 7 integrally formed by 3D printing;

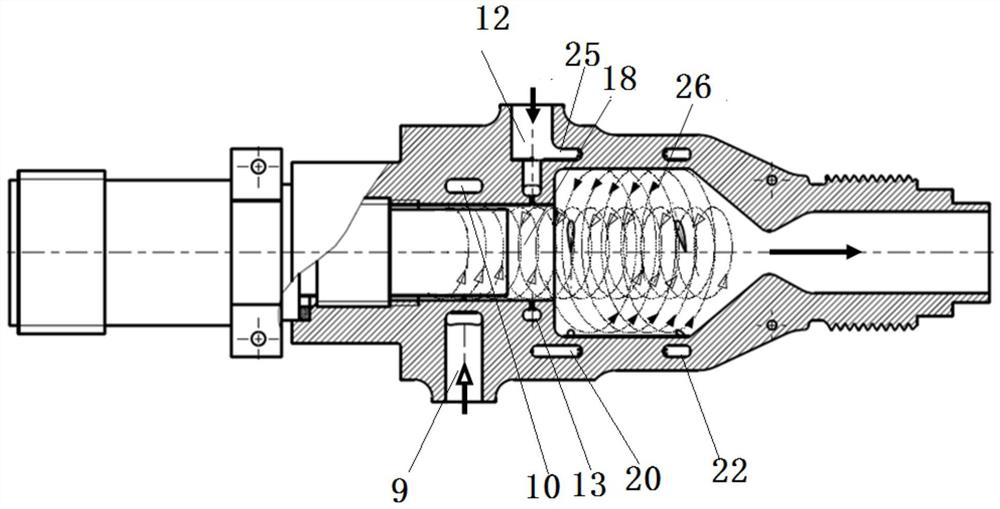

[0052] Such as figure 2 , 3 , 4, the head pipe section 4 includes a central hole 8, an oxidizer interface 9, an oxidant annular gas collection chamber 10, an oxidant nozzle 11, a fuel interface 12, an ignition fuel annular gas collection chamber 13, an ignition fuel nozzle 14 and a body pipe section 5. The chamber pressure measurement interface 15 connected to the front end;

[0053] The central hole 8 is opened axially alo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com