Combined gasification furnace burner

A gasifier and combined technology, which is applied in the field of combined gasifier burners, can solve the problem of the gasifier heating up, the pressure increasing speed is slow, the inability to accurately judge the gasifier temperature, and the small amount of coal input in the gasifier, etc. problems, to achieve the effect of increasing the amount of coal input, reducing the impact, and reducing the economic loss of the enterprise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following is attached Figure 1-Figure 7 For a further detailed introduction to the present invention, it should be noted that the orientation words such as up, down, left, and right involved in this application are consistent with the up, down, left, and right orientations of each figure in the accompanying drawings, and all the orientation words are only for clearly expressing the structure of the application , but not limited to restrictions on the specific location of the actual product.

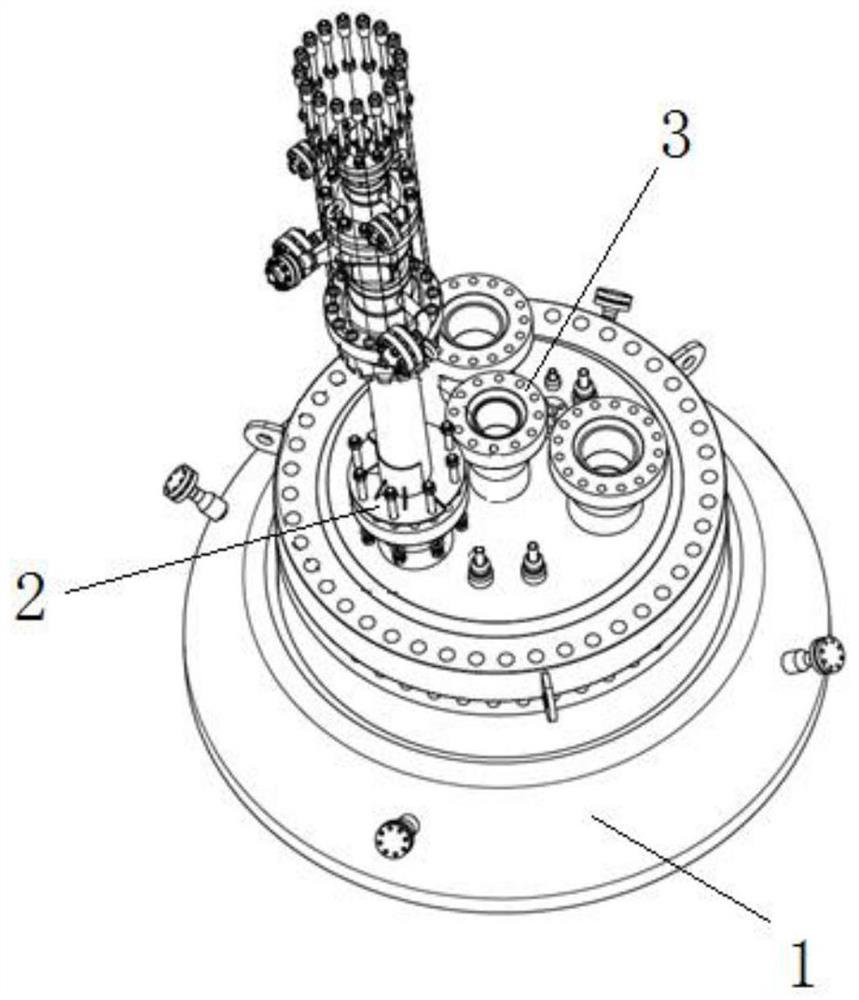

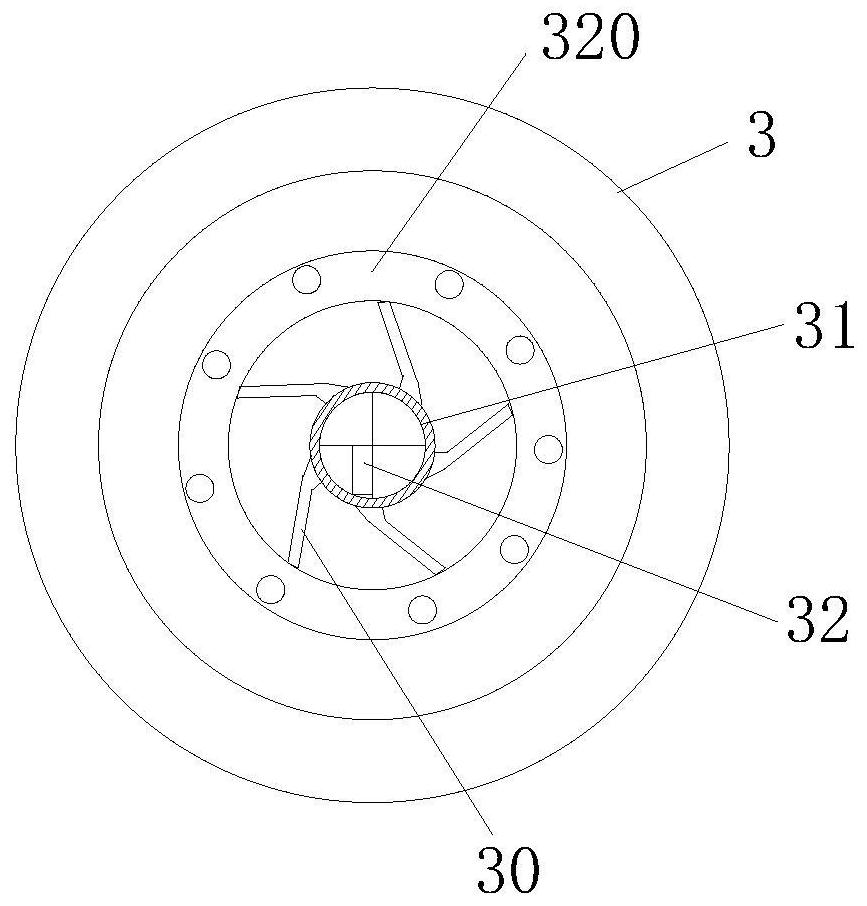

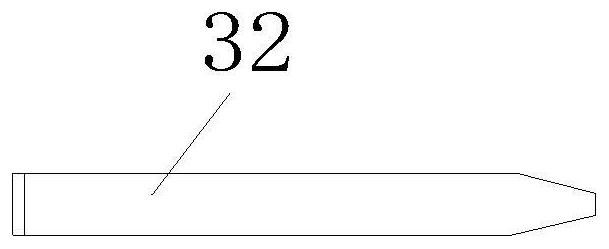

[0034] A combined gasifier burner, such as figure 1 As shown, including the burner base 1, the burner base 1 is provided with an ignition start-up burner 3, and the outside of the ignition start-up burner 3 is provided with at least three pulverized coal burners 2, and each pulverized coal burner 2 is evenly distributed on the same On the virtual circle, the center of the virtual circle is located on the geometric center of the ignition burner 3 . The burner base 1 is connec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com