Multi-burner coal water slurry gasification furnace

A technology of coal water slurry and gasifier, applied in gasification process, details of gasification device, gasification of granular/powdered fuel, etc., can solve problems such as damage to refractory materials, reduce safety of gasifier, etc., and achieve extended service life, improving the ability to process coal-water slurry, and protecting the effect of the water wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

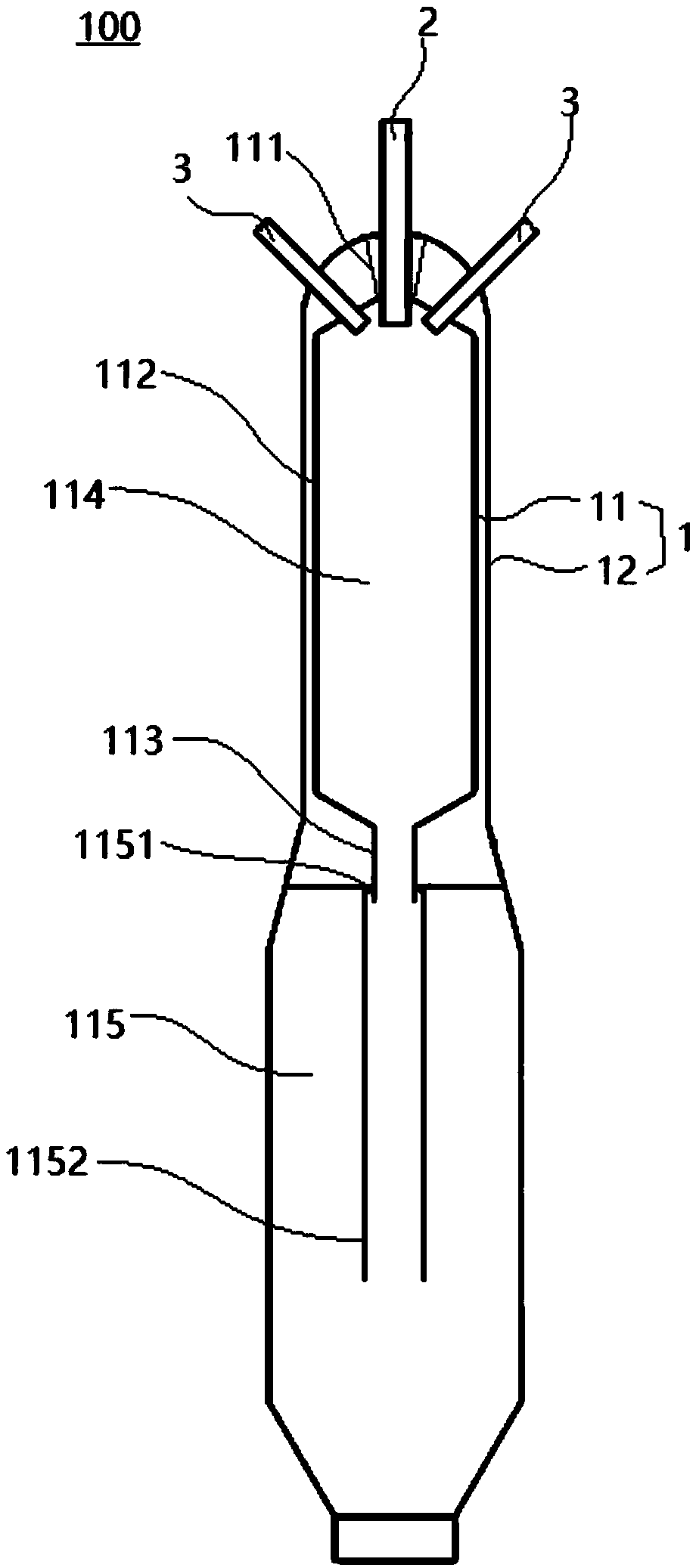

[0026] The following is based on figure 1 Describe the multi-burner coal-water slurry gasifier 100 according to the embodiment of the present invention, such as figure 1 As shown, a multi-burner coal-water slurry gasifier 100 according to an embodiment of the present invention includes a shell 1 , a central combined burner 2 and a plurality of process burners 3 .

[0027] The casing 1 has a water-cooled wall and defines a gasification chamber 114 and a quenching chamber 115. The gasification chamber 114 communicates with the quenching c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com