Device and method for preparing thermal fuel gas for glass kiln by anthracite pressurized moving bed

A technology of glass kiln and fuel gas, applied in the field of coal-to-gas, which can solve the problems of high pollution, low energy utilization rate, and small gas generation, and achieve the effects of high energy utilization rate, reduced difficulty in wastewater treatment, and reduced design scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

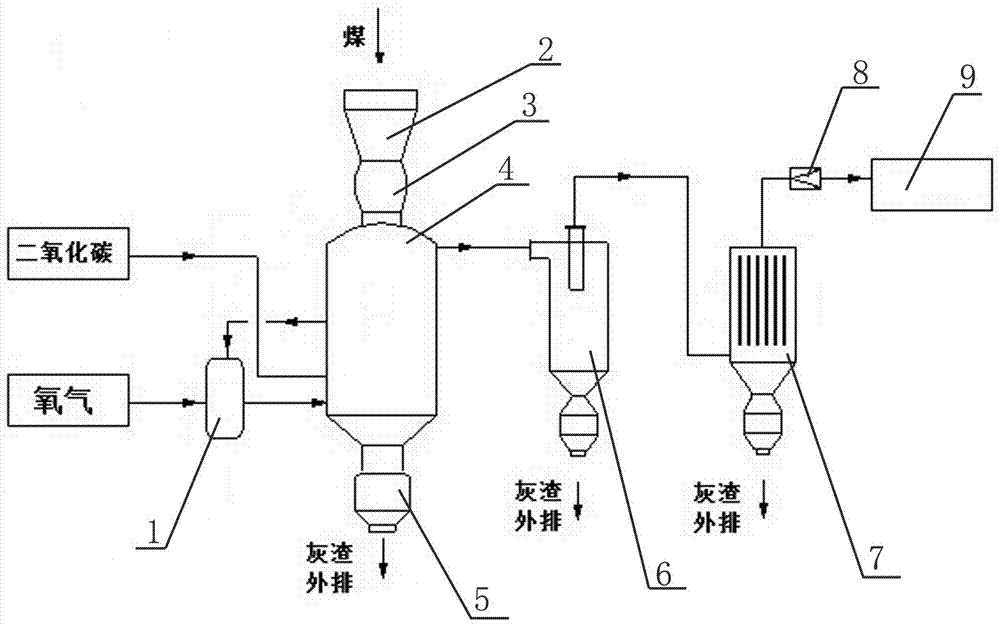

[0034] A method for preparing hot fuel gas for a glass kiln with an anthracite pressurized moving bed, comprising the following steps:

[0035] a. Add anthracite from the raw coal bunker to the gasifier;

[0036] b. Pure oxygen and recovered CO from oxygen-making equipment in the future 2 The gas is mixed in the mixer to form a gasification agent, and the gasification agent is transported to the gasification furnace body by the mixer;

[0037] c. The gasification furnace body is divided into drying layer, dry distillation layer, reduction layer, oxidation layer and ash layer from top to bottom. The gasification agent passing into the gasification furnace body first exchanges heat with the ash layer, and then enters the oxide layer with oxygen and A violent combustion reaction occurs when the hot coal seam contacts, and CO is generated 2 ; The gas after the oxidation reaction enters the reducing layer upwards, and in the reducing layer CO 2 It reacts with coal to generate CO...

Embodiment 2

[0044] The particle size is 6~50 mm, the as received basis ash content is 13~15%, the as received basis fixed carbon content is 70~75%, the as received basis volatile matter content is 6~8%, the as received basis total sulfur content is less than 0.5%, Softening temperature (T 2 ) greater than 1500 ℃, crushing strength greater than 96%, and thermal stability greater than 95% are added to the gasifier through coal bunkers and coal locks.

[0045] Gasification agent oxygen 2165 Nm 3 / h (99.6%, 0.6 MPa) and CO 2 2165 Nm 3 / h (0.6 MPa), after mixing, enter the gasifier for redox reaction. Into the coil CO 2 The temperature is 10°C, and the outlet coil temperature is about 350°C.

[0046] The heat production fuel gas volume of a single furnace is 10324 Nm 3 / h, pressure 0.5 MPa, temperature about 500 ℃, after dust removal by cyclone dust collector and dry dust collector (dust content is less than 10 mg / Nm³, pressure 0.45 MPa, temperature 450 ℃), after the pressure is adjuste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Softening temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com