Construction robot of intelligent electric power engineering cable laying device

A technology of laying device and intelligent power, which is applied in the directions of cable installation device, cable installation, and cable laying equipment, can solve the problems of low power cable laying efficiency and low construction efficiency, so as to avoid low construction efficiency and improve construction efficiency. , the effect of improving the efficiency of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

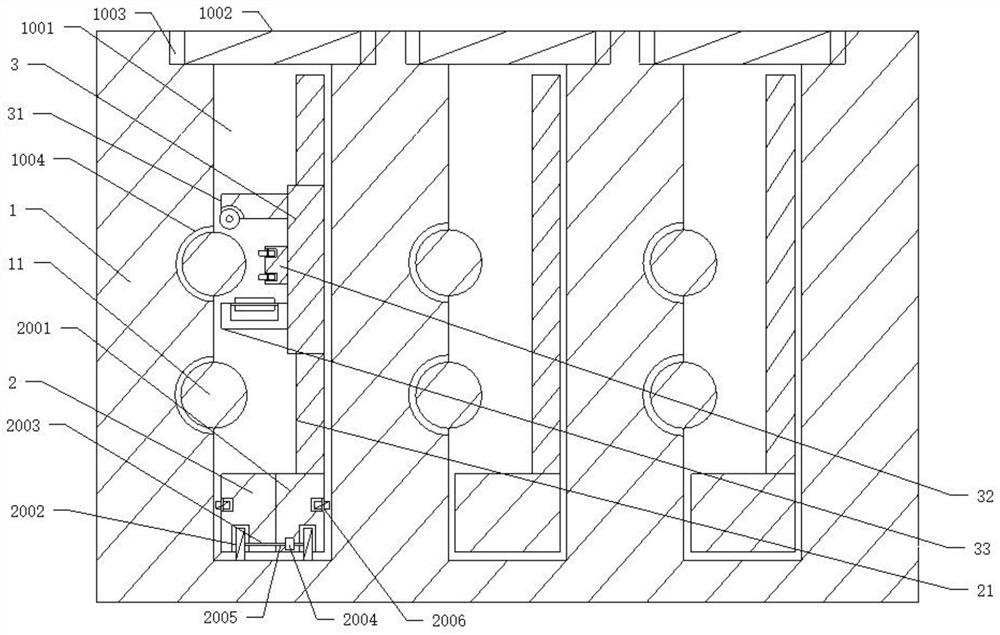

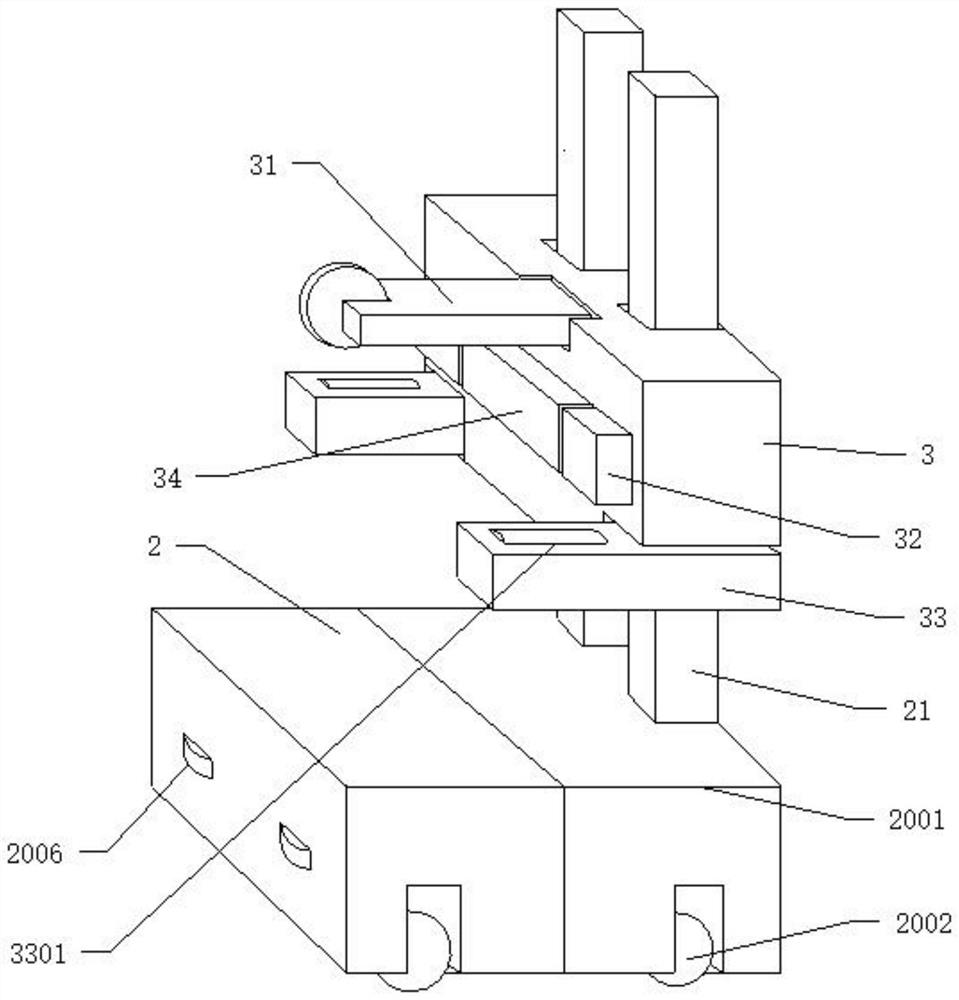

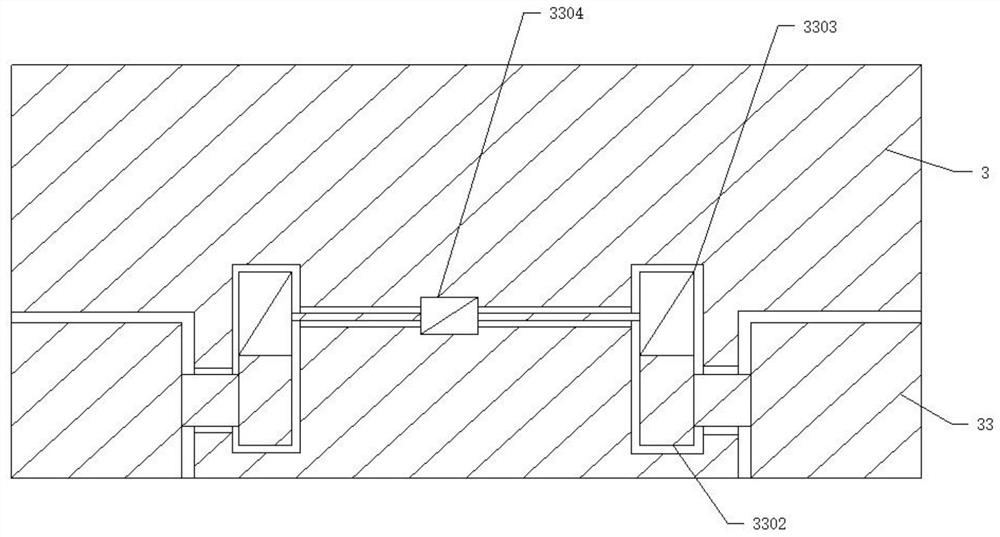

[0052] like Figure 1 to Figure 15 As shown, an intelligent power engineering cable laying device includes connecting pipes, inspection robots, and construction robots;

[0053] The connecting pipeline includes a pipeline module 1, a cable 11, and a sealing cover 1002;

[0054] The pipeline modules 1 are respectively provided with pipeline grooves 1001, and the pipeline grooves 1001 respectively include cable fixing grooves 1004 arranged side by side on the pipeline modules 1, and the cables 11 are fixedly arranged in the cable fixing grooves In 1004, the two sides of the cable fixing groove 1004 are respectively provided with locking grooves 1005, the fixing module 1 is provided with a sealing groove 1003 corresponding to the pipe groove 1001, and the sealing groove 1003 is provided with A sealing cover 1002 for sealing the pipe groove 1001.

[0055] The pipeline modules 1 are buried in the ground, and the pipeline modules 1 are connected side by side correspondingly. A plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com