A cotton thread detection device

A detection device, cotton thread technology, applied in the direction of measuring device, using stable tension/pressure test material strength, instruments, etc., can solve the problem that the detection efficiency cannot be improved, and achieve the effect of improving the detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0046] As an embodiment, the force measuring assembly further includes a plurality of struts 21 with one end fixed to the bottom of the inner hole 16, the struts 21 are arranged vertically, and the dynamometer 19 is located between the plurality of struts 21, so that in the When the bottom rod 17 is moved downward by the structural member 4 under the action of gravity, the support rod 21 will support the bottom rod 17 to avoid damage to the dynamometer 19 .

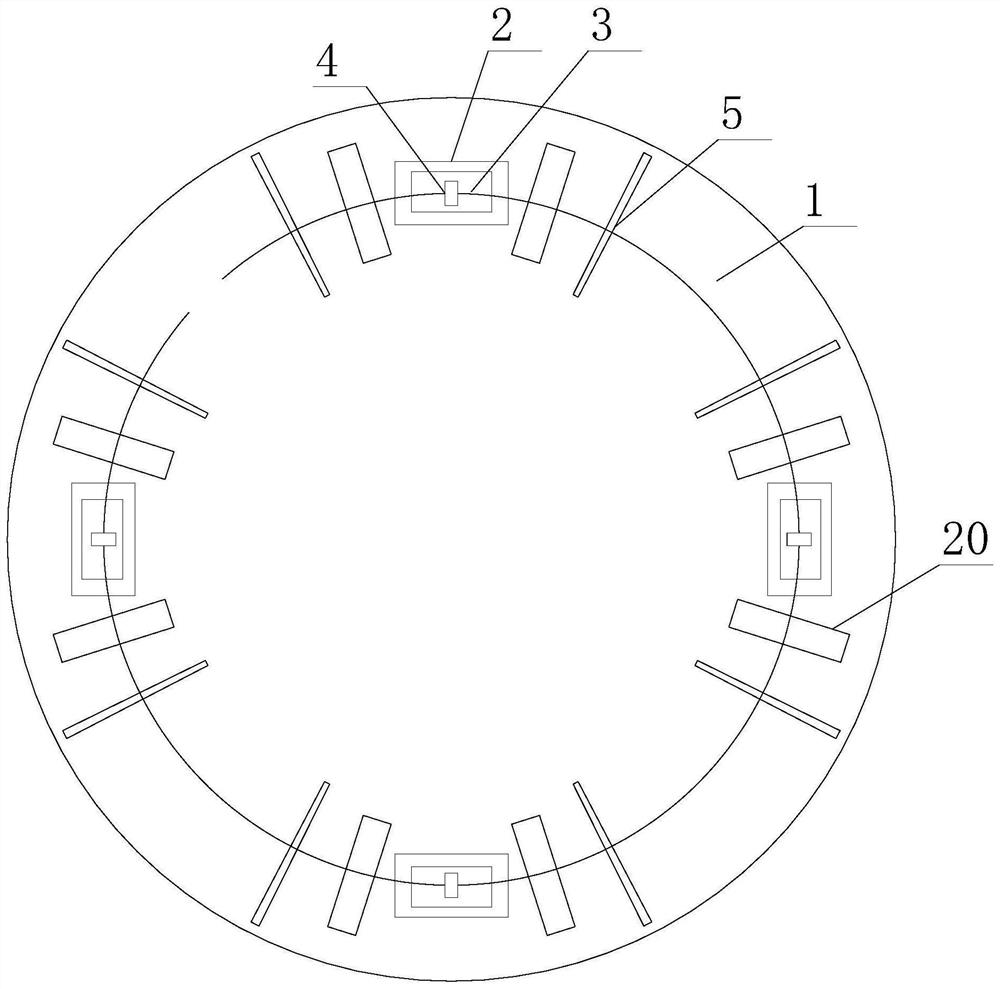

[0047] As an implementation, as figure 2 As shown, it includes a plurality of projection marks 20 arranged on the upper end surface of the pressure-bearing block 1 . The length and width of the projection marks 20 are respectively equal to the length and width of the fixing block 14 , and are located directly below the corresponding fixing block 14 . In this way, when a piece of cotton thread is placed on the upper end face of the pressure-bearing block 1, the cotton thread is passed through the projection mark 20, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com