Manufacturing and using methods of inwards-concave flat-inserting type drill rod joint

A drill pipe joint and drill pipe technology, which is applied to drill pipes, drill pipes, drilling equipment, etc., can solve the problems of requiring a lot of raw materials, complex manufacturing processes, and large lathe processing capacity, so as to reduce manufacturing costs, simplify manufacturing processes, The effect of shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

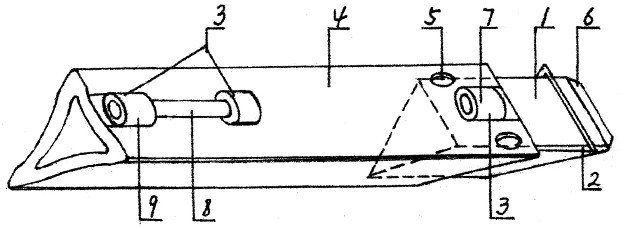

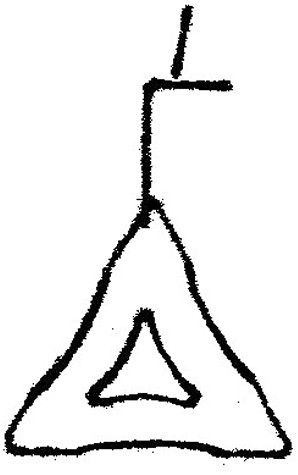

[0023] Such as figure 1 , 2, and 3, a method for manufacturing and using an inwardly recessed flat plug-in drill pipe joint, the structure is composed of a plug-in section 1 of the rod body 4 of the drill pipe, a sealing washer 2, and a fastening device for connecting the drill pipe 3 consists of three parts; therefore, the manufacturing method is as follows: the plug-in section 1 is made by cutting and cutting a section of the profile material of the above-mentioned triangular arc-convex drill pipe, and the specification cross-section of the profile used in the plug-in section 1 is less than A thickness level of the specification section of the profile used to make the drill pipe body (that is, the outer section of the plug-in section is equal to the inner section of the drill-pipe profile), such a design matching just enables the plug-in section 1 to be inserted into the body 4 of the drill pipe for one Cut (generally the length of insertion is 10-30 cm); that is, the tota...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com