Integrated chimney and cooling tower structure system of diagonal cable net and construction method thereof

A technology of cable-stayed cable towers and cable nets, which is applied in the structural system field of chimney-air-cooling towers in thermal power plants, can solve the problems of large amount of concrete air-cooling tower materials, a large number of aerial operations, and high safety risks, and shorten the construction time Period, save land, improve the effect of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

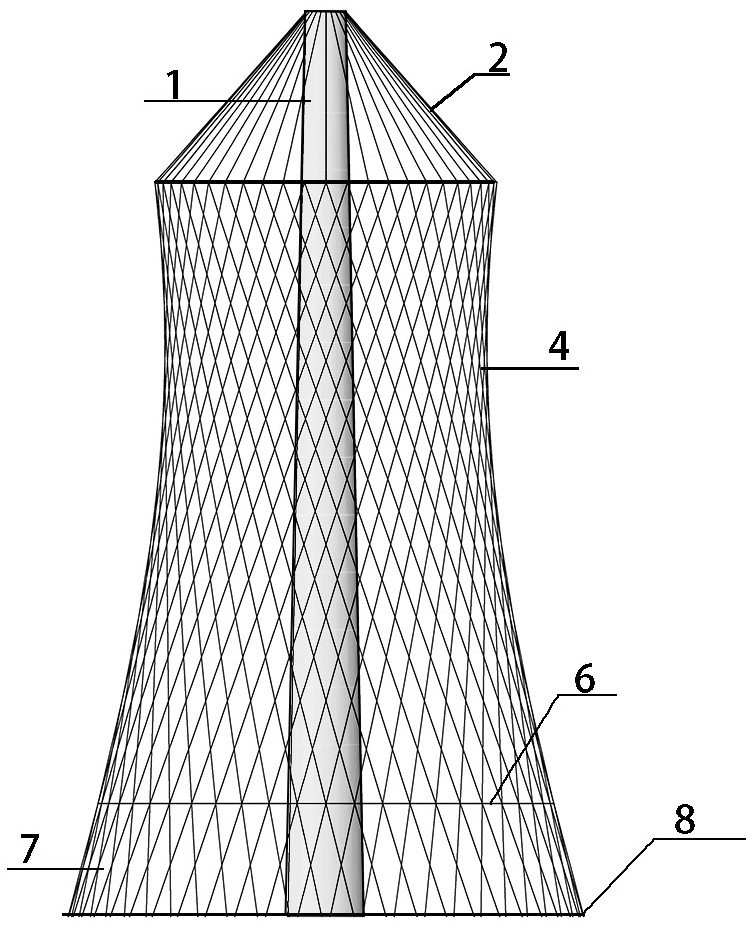

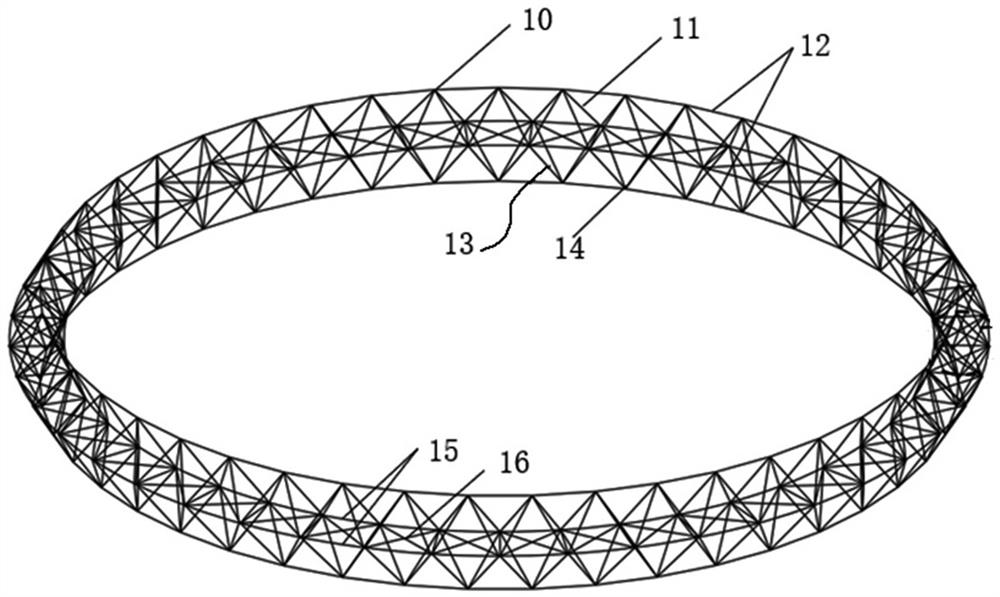

[0056] The diameter at zero meter at the bottom of the air-cooling tower (pillar center) is 138.5m, the outlet diameter of the air-cooling tower is 90m, the diameter of the air inlet of the air-cooling tower is 121.6m, the throat diameter of the pit cooling tower is 86m, and the height is 148.5m. The height of the pit cooling tower is 198m. The height of the air inlet of the tower is 30.5m; the diameter of the bottom of the chimney 1 is 20m, the diameter of the top is 10m, the wall thickness is 3m to 5m, and the height of the chimney 1 is 248m. The tension support is provided by the chimney 1, and the single-layer straight cable is used as the busbar to cross-tension obliquely between the upper and lower ring beams to form a single-layer hyperboloid, and the membrane material is laid on the inside or outside of the cable net. The specific construction method is as follows:

[0057] (1) First, the structural construction of the chimney 1 is carried out. The chimney 1 is a cast-...

Embodiment 2

[0065] The diameter at zero meter at the bottom of the air cooling tower is 138.5m, the diameter of the air cooling tower outlet is 90m, the diameter of the air inlet of the air cooling tower is 121.6m, the diameter of the throat of the pit cooling tower is 86m, the height is 148.5m, the height of the air cooling tower is 198m, and the height of the air inlet of the air cooling tower is 30.5m m; chimney 1 has a bottom diameter of 20m, a top diameter of 10m, a wall thickness of 3m to 5m, and a height of chimney 1 of 248m. The tension support is provided by the chimney 1, and two layers of straight cables are used as the generatrix to cross-tension obliquely between the upper and lower ring beams to form a double-layer hyperboloid, and the membrane is laid on the inside or outside of the cable net. The specific construction method is as follows:

[0066] (1) Firstly, the structural construction of the chimney 1 is carried out. The chimney 1 is a cast-in-place concrete structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com