Device and method for culturing high-throughput organoids by using micro-array deep well

A culture device and microarray technology, applied in the field of in vitro culture and analysis of organoids, can solve the problems of relying on operating techniques, low efficiency of organoid formation, and uneven size of organoids cultured in vitro, so as to achieve good application prospects and improve the number of inconsistencies , The effect of improving the efficiency of organoid formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

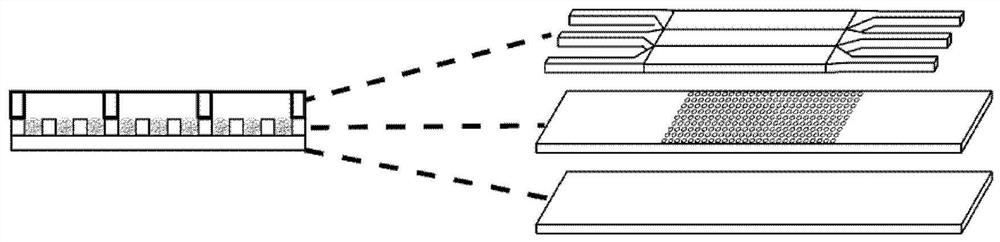

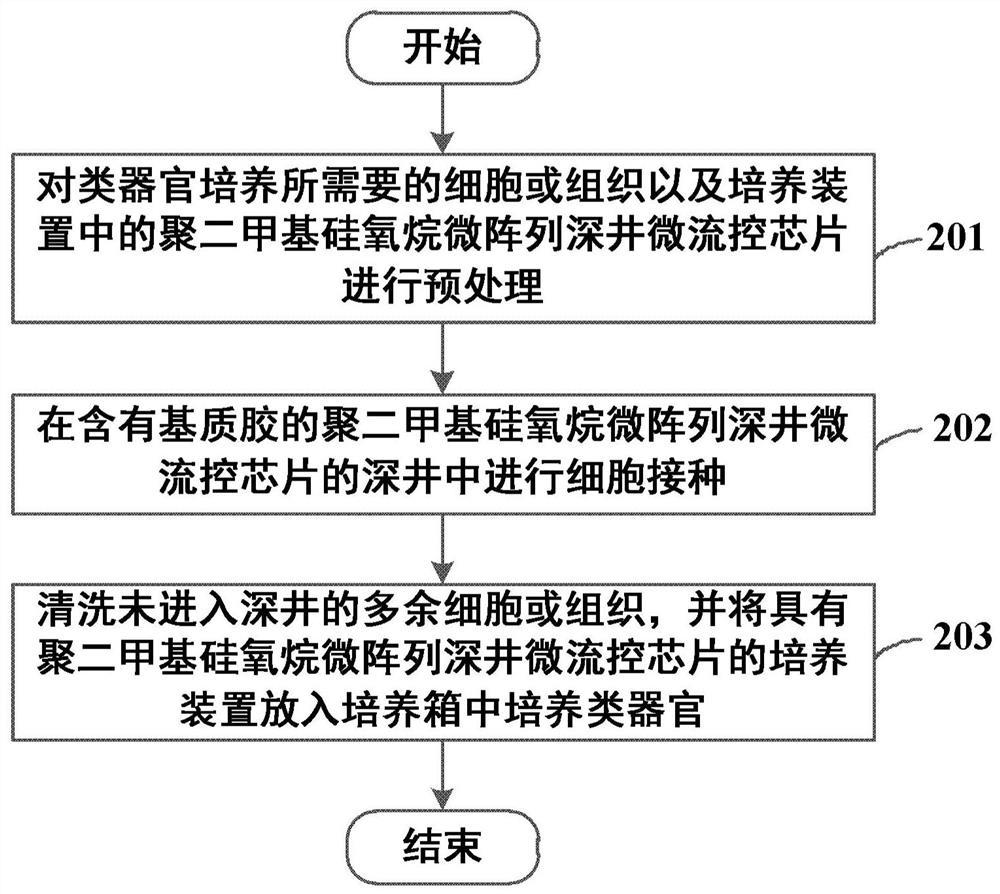

[0074] This embodiment provides a device and method for culturing high-throughput organoids using microarray deep wells, wherein the device is used for culturing primary mouse small intestine organoids, which specifically includes the following steps:

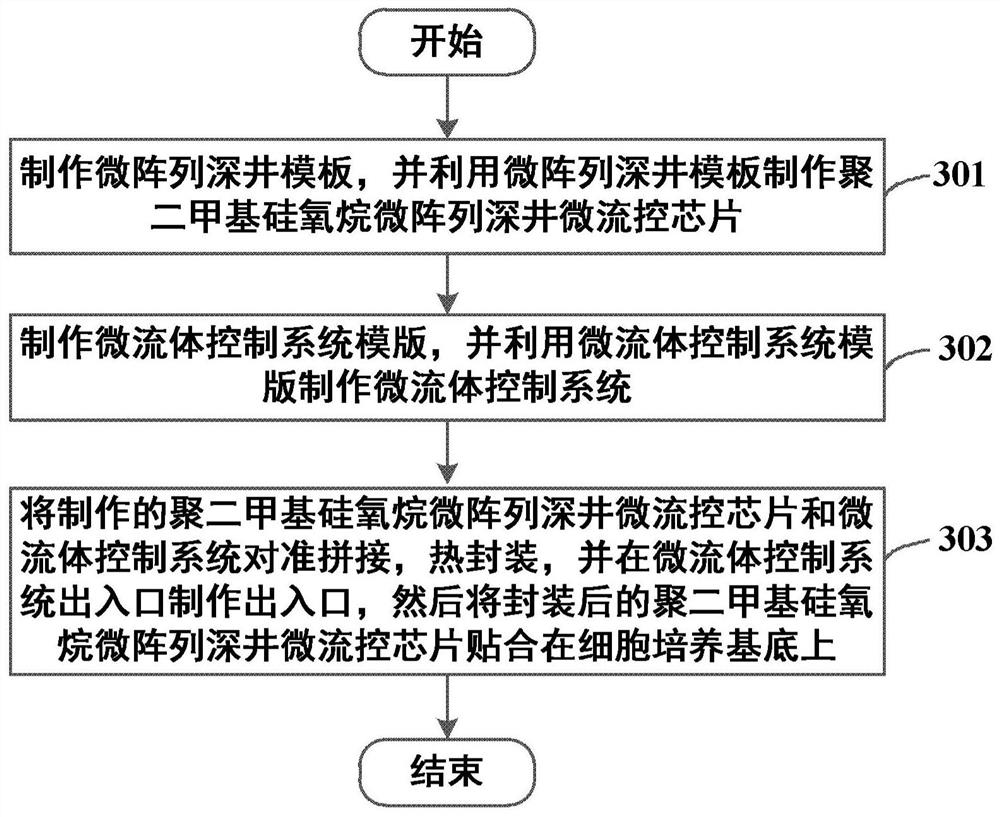

[0075] 1. Fabrication of polydimethylsiloxane microarray deep well microfluidic chip. First, using photolithography technology, a diameter of 200 μm, a height of 200 μm, and a distance between the centers of any two adjacent micropillars of 400 μm are produced. The ratio of polydimethylsiloxane A liquid and coagulant B liquid is 10:1, after fully mixing, degassing in vacuum, pouring on the obtained photolithographic micropillar mold, curing at 85°C for two hours The mold is separated from the polydimethylsiloxane.

[0076] 2. Pretreatment and assembly of polydimethylsiloxane microarray deep well microfluidic chip. Before the polydimethylsiloxane microarray deep-well microfluidic chip is inserted into the cells, the chip surfa...

Embodiment 2

[0081] This embodiment provides a high-throughput culture method for tumor organoids, comprising the following steps:

[0082] 1. Fabrication of polydimethylsiloxane microarray deep well microfluidic chip. First, using photolithography technology, a diameter of 200 μm, a height of 200 μm, and a distance between the centers of any two adjacent micropillars of 400 μm are fabricated. The ratio of polydimethylsiloxane A liquid and B liquid is 10:1, after fully mixing, degassing in vacuum, pouring on the obtained photolithography micro-column mold, curing at 85 °C for two hours, the mold and Dimethicone isolated. Among them, liquid A is polydimethylsiloxane PDMS liquid, and liquid B is a coagulant.

[0083] 2. Pretreatment and assembly of polydimethylsiloxane microarray deep well microfluidic chips. Before the polydimethylsiloxane microarray deep-well microfluidic chip is inserted into the cells, the chip surface and the bottom surface are dedusted, and the surface dust is remov...

Embodiment 3

[0088] Such as Figure 8 as shown, Figure 8 It is a schematic diagram of drug testing performed according to the microfluidic control system and polydimethylsiloxane microarray deep well microfluidic chip in Example 3 of the present disclosure. This embodiment provides a method for culturing tumor organoids for drug testing, comprising the following steps:

[0089] 1. Fabrication of polydimethylsiloxane microarray deep well microfluidic chip. Firstly, a polydimethylsiloxane microarray deep-well chip template with a diameter of 200 μm, a height of 200 μm, and a center-to-center distance of 400 μm between any two adjacent microcolumns was fabricated using photolithography technology. The ratio of polydimethylsiloxane A liquid and B liquid is 10:1, after fully mixing, degassing in vacuum, pouring on the obtained photolithography micro-column mold, curing at 85 °C for two hours, the mold and Dimethicone isolated. Among them, liquid A is polydimethylsiloxane PDMS liquid, and l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com