Low-conductivity dielectric cooling liquid for ethylene glycol type phased array radar, and application of low-conductivity dielectric cooling liquid

A technology of phased array radar and low conductivity, which is applied in the direction of using re-radiation, radio wave measurement system, radio wave reflection/re-radiation, etc., which can solve the problem of high conductivity of coolant, short circuit and burning of electronic components of radar electronic equipment , equipment can not be used and other problems, to achieve excellent defoaming effect, good protection effect, prevent precipitation and scaling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

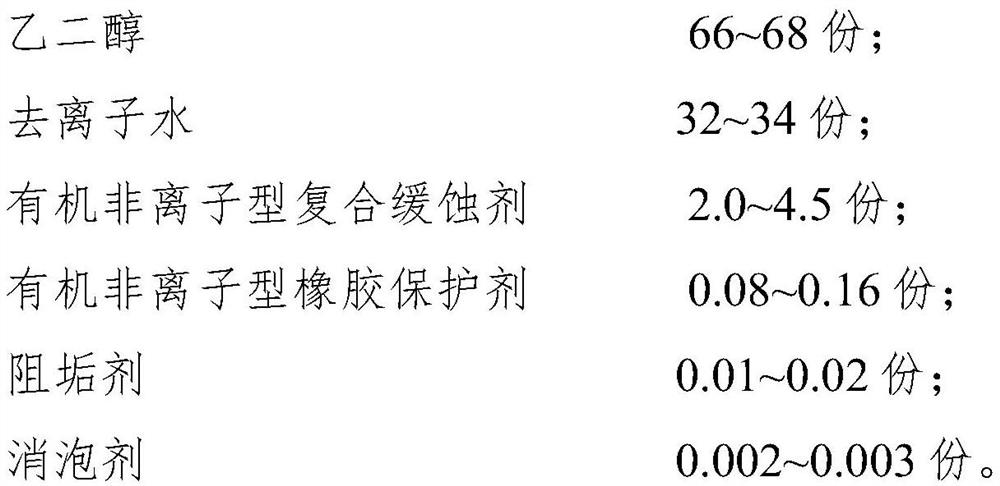

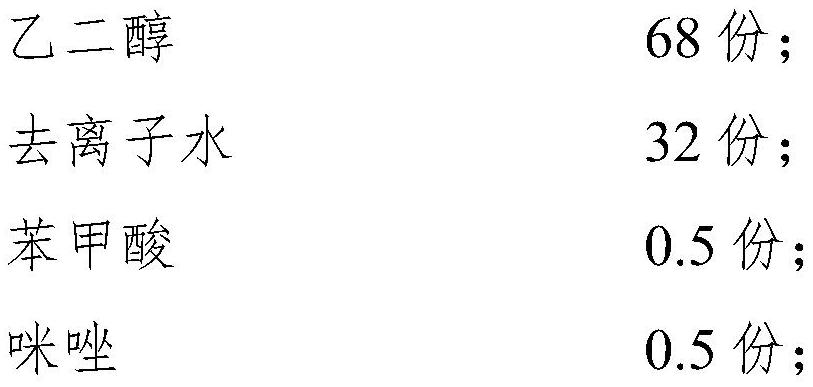

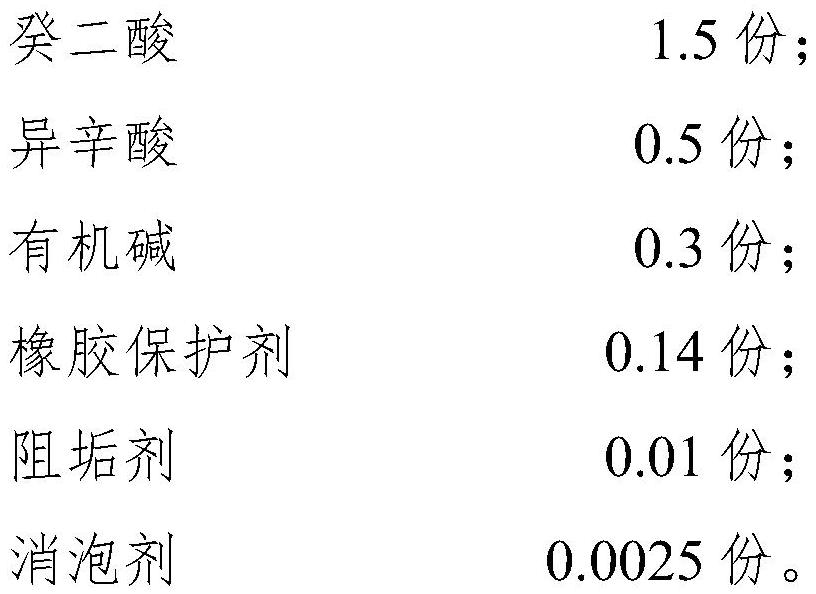

[0032] Coolant formula:

[0033] Ethylene glycol 68kg; deionized water 32kg; benzoic acid 0.5kg, imidazole 0.5kg, sebacic acid 1.5kg, isooctanoic acid 0.5kg, organic base 0.3kg; mercaptobenzotriazole 0.08kg, dextrin 0.06kg; Oxyethylene polyoxypropylene ether (molecular weight: 2000) 2.5g; polyacrylic acid 0.01kg.

[0034] Preparation method of coolant:

[0035] First, weigh 5kg of deionized water and raise the temperature to 80℃~90℃, add 0.06kg of dextrin, heat and stir until completely dissolved, then add 27kg of deionized water and 38kg of ethylene glycol, and then heat up to 40℃~50℃, then add Benzoic acid 0.5kg, imidazole 0.5kg, sebacic acid 1.5kg, isooctanoic acid 0.5kg, organic base 0.3kg, mercaptobenzotriazole 0.08kg, polyoxyethylene polyoxypropylene ether 2.5g, polyacrylic acid 0.01kg, and Maintain the temperature at 40°C-50°C, heat and stir until the above components are completely dissolved, finally add 30kg of ethylene glycol, stir at room temperature for 2-3 hours...

Embodiment 2

[0037] Coolant formula:

[0038] Ethylene glycol 66kg; deionized water 34kg; p-tert-butylbenzoic acid 0.5kg, organic base 0.4kg, sebacic acid 1.6kg, imidazole 0.2kg, cinnamic acid 0.1kg; pimelic acid 0.28kg; mercaptobenzotriazepam azole 0.08kg, dextrin 0.06kg; polyoxyethylene polyoxypropylene ether (molecular weight: 2000) 2.5g; polyacrylic acid 0.01kg.

[0039] Preparation method of coolant:

[0040] First, weigh 5kg of deionized water and raise the temperature to 80°C-90°C, add 0.06kg of dextrin, heat and stir until completely dissolved, then add 27kg of deionized water and 36kg of ethylene glycol, and then heat up to 40°C-50°C, then add 0.5kg p-tert-butylbenzoic acid, 0.2kg imidazole, 0.4kg organic base, 1.6kg sebacic acid, 0.1kg cinnamic acid, 0.28kg pimelic acid, 0.08kg mercaptobenzotriazole, polyoxyethylene polyoxypropylene Ether 2.5g, polyacrylic acid 0.01kg, and maintain the temperature at 40℃~50℃, heat and stir until the above components are completely dissolved, fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com