Method, apparatus and system for determining optimum operation recipe for optical film-thickness measuring device

A measuring device, optical technology, applied in the direction of measuring device, grinding device, work carrier, etc., can solve the problems of time-consuming, time-consuming, dependence, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

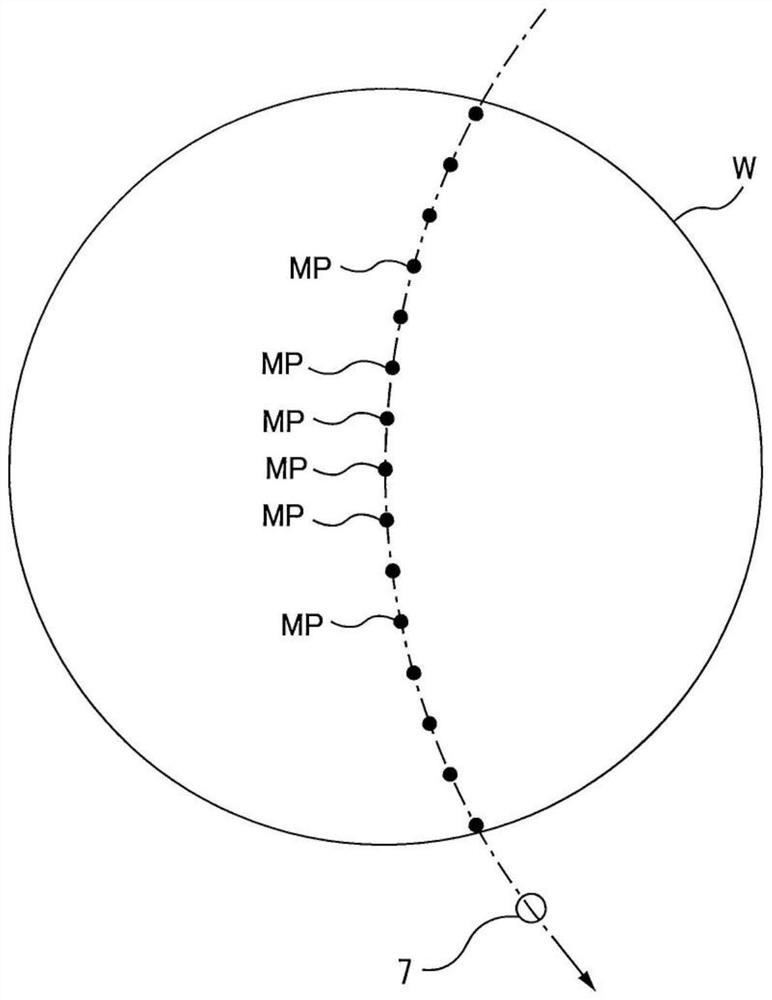

[0080] Hereinafter, embodiments of the present invention will be described with reference to the drawings. figure 1 It is a schematic diagram which shows one embodiment of a grinding|polishing apparatus. Such as figure 1 As shown, the polishing device has: a polishing table 3 supporting the polishing pad 2; a wafer W as an example of a substrate is pressed on the polishing head 1 of the polishing pad 2; a table motor 6 is made to rotate the polishing table 3; A slurry supply nozzle 5 for supplying slurry. The upper surface of the polishing pad 2 constitutes a polishing surface 2 a for polishing the wafer W. As shown in FIG.

[0081] The grinding head 1 is connected to the head shaft 10, and the grinding head 1 and the head shaft 10 rotate together in the direction indicated by the arrow. The polishing table 3 is connected to a table motor 6, and the table motor 6 is configured to rotate the polishing table 3 and the polishing pad 2 in the direction indicated by the arrow. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com