Medium-sized gear shaping machine clamp pallet changer mechanism and operation method

A gear shaping machine and workbench technology, which is applied in the direction of gear cutting machines, gear teeth, mechanical equipment, etc., can solve the problem that medium-sized gear shapers cannot use double workbenches, and achieve the effects of improving convenience, high flexibility, and ensuring positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

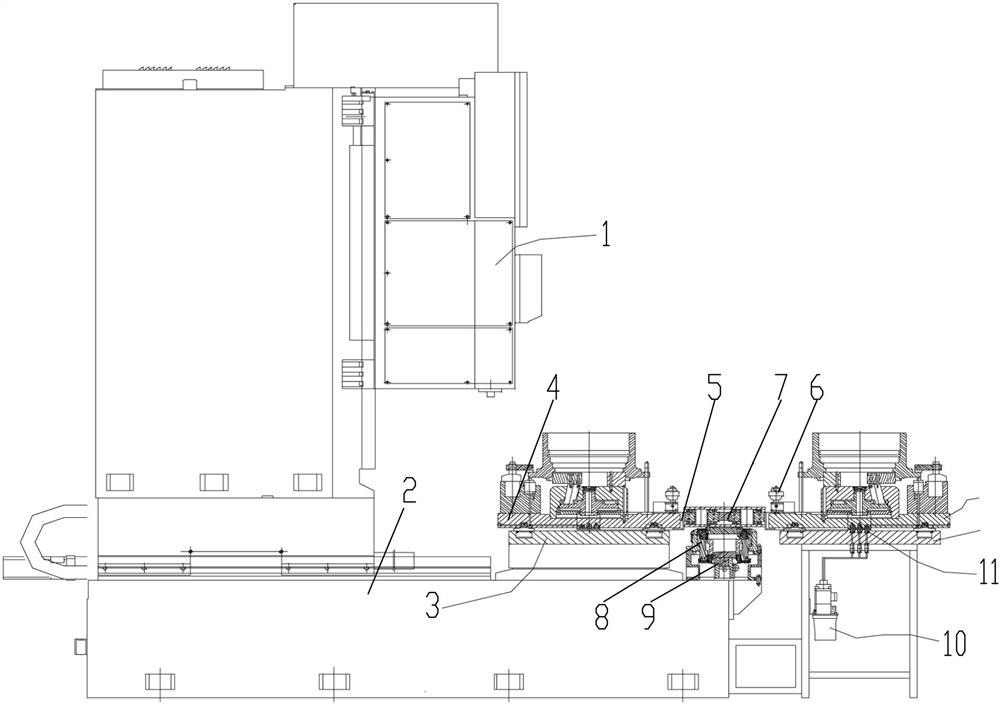

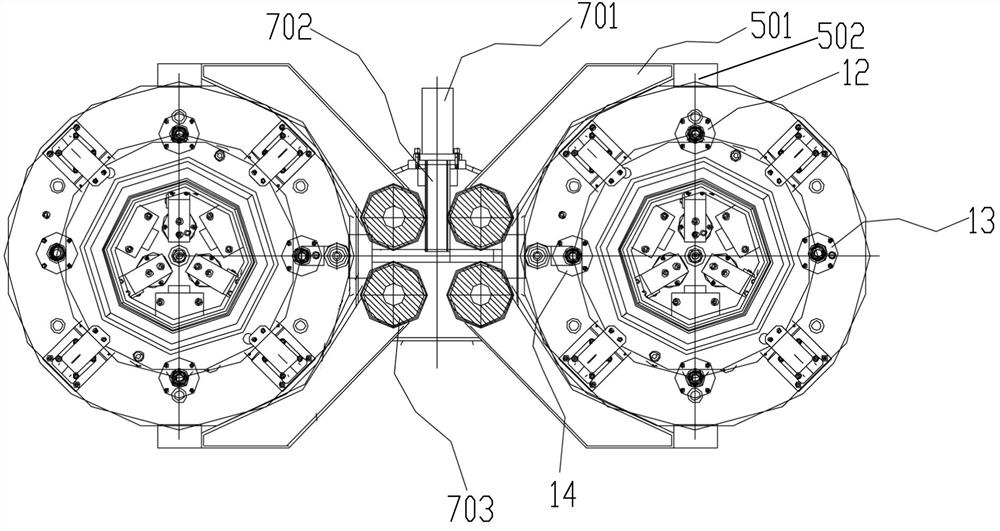

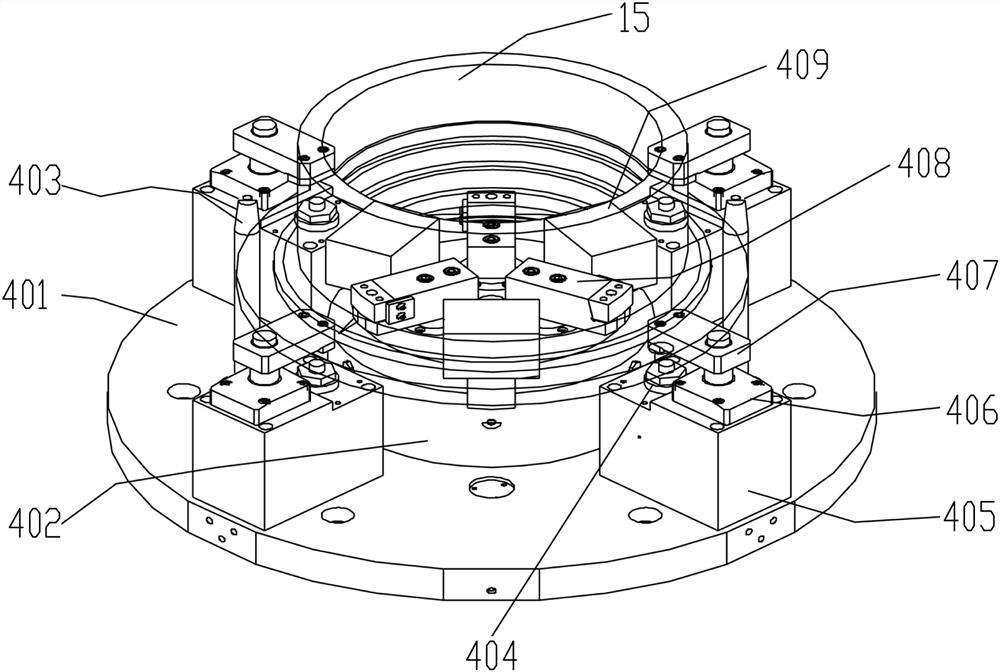

[0048] see Figure 1-5 , a medium-sized gear shaping machine clamp exchange table mechanism, which includes a gear shaping machine body 2, a gear shaping machine body 1 is arranged on the gear shaping machine body 2, and positioning The table top 3, the fixture body 4 for clamping the workpiece is installed on the positioning table 3 through the zero point locator, and the clamp body 4 is matched with the clamping claw structure 5 for clamping it. The clamping claw structure 5 is matched with the clamping power mechanism 7 for providing clamping force, and the clamping power mechanism 7 is fixedly installed on the top of the rotary mechanism 9 for driving the entire clamping claw structure 5 to rotate , the inside of the slewing mechanism 9 and the lifting mechanism 8 for driving its overall lifting, the lifting mechanism 8 is fixedly installed on the gear shaper machine body 2 and is located between two positioning tables 3 . This mechanism adopts a double-station structure, w...

Embodiment 2

[0059] The operation method of the clamp exchange table mechanism of the medium-sized gear shaping machine includes the following steps:

[0060] Step 1: Position and install the workpiece 15 on the fixture body 4;

[0061] Step 2: Start the clamping power mechanism 7, and drive the clamping claw structure 5 to clamp the two clamp bodies 4;

[0062] Step 3: start the lifting mechanism 8, and drive the entire clamping power mechanism 7, the fixture body 4 and the workpiece 15 to rise through the lifting mechanism 8;

[0063] Step 4: After the two groups of fixture bodies 4 are raised, start the rotary mechanism 9, drive the fixture body 4 to rotate 180° through the rotary mechanism 9, send the workpiece 15 to the gear shaping machine body 2, and after the lifting mechanism 8 is reset, The fixture body 4 and the positioning table 3 are positioned and fixed by the zero point locator;

[0064] Step 5: Start the gear shaping machine body 1 to perform gear shaping processing on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com