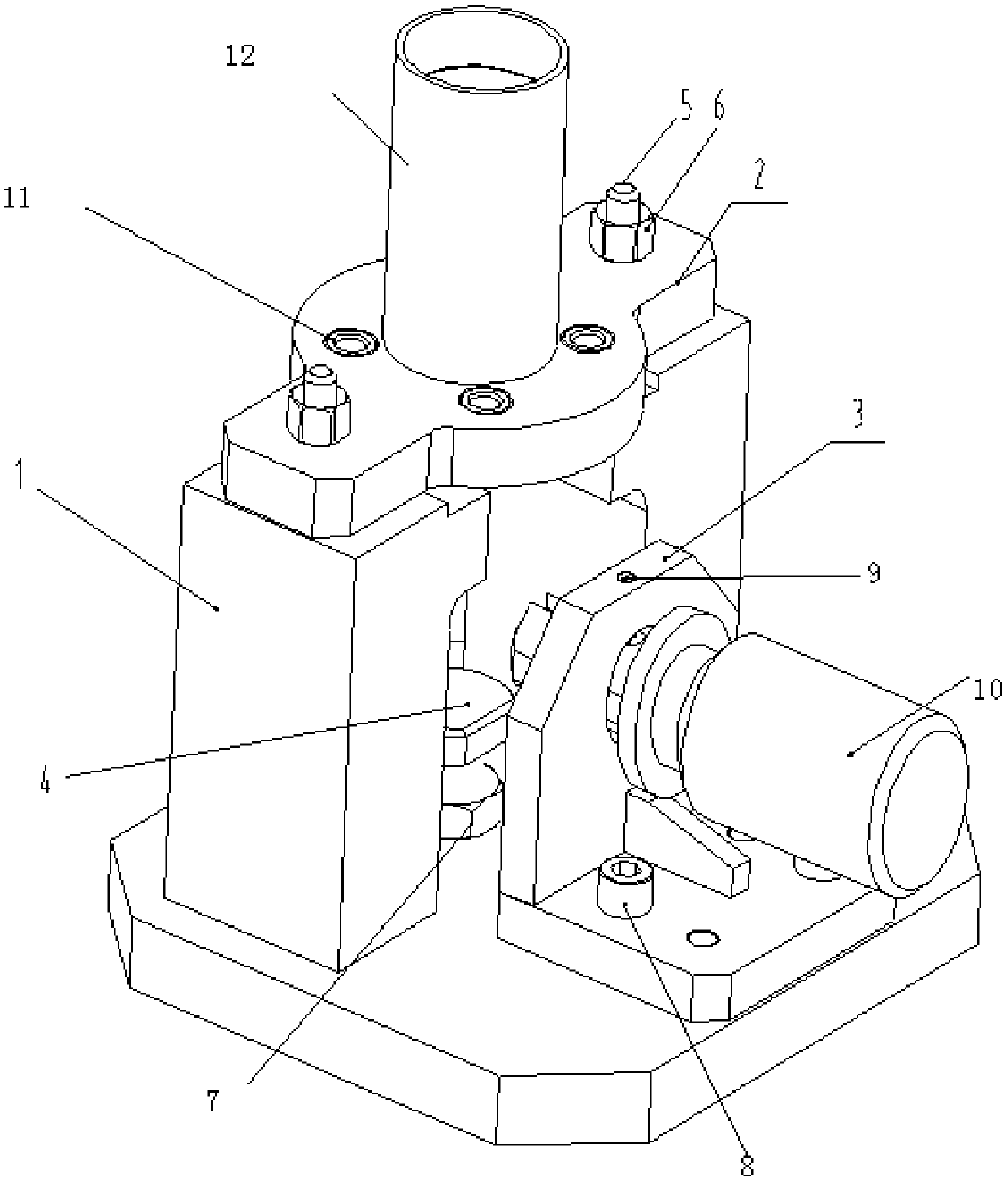

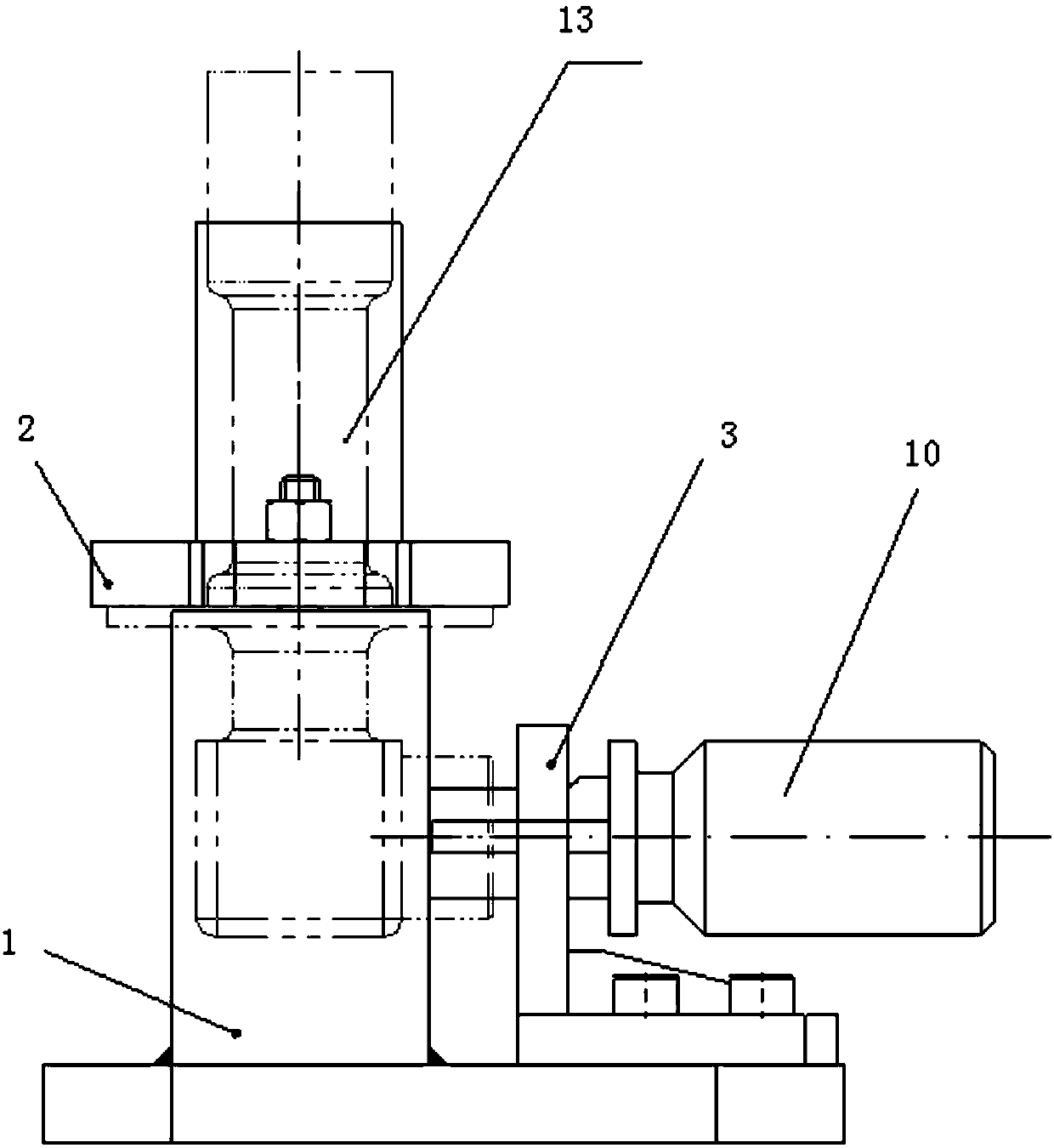

Flange plate drilling clamp of L-shaped tubular part

A drilling jig and tubular technology, applied in the field of flange drilling jigs, can solve problems such as tool tilt and slippage, parts scrapping, poor tool rigidity, etc., to achieve convenient clamping and disassembly, simple structure, and ensure positional accuracy and the effect of size requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] A flange drilling jig for L-shaped tubular parts, the jig has a pair of uprights 1 and supports 3 on the base, a supporting platform 4 on the base between the uprights 1, and opposite The steps, wherein the flange of the L-shaped tubular part is placed, and a drill template 2 is installed on the upper end surface, and the drill template 2 has a conduit 12 fitted with a gap fit with one end of the L-shaped tubular part; on the support 3, there is A guide pin 10 fitted with the other end of the L-shaped tubular part in clearance fit, the guide pin 10 has a planar part cut along the axial direction and an arc surface part not cut.

[0014] The drill template 2 has a drill bushing 11, and the drill template 2 is installed on the column 1 through stop screws 5 and nuts 6, and positioned by positioning pins. The lower end of the supporting platform 4 has studs, which are installed on the thin nuts 7 of the base. The support 3 is an L-shaped plate structure, and its lower end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com