Rolling method for steel for non-quenched-and-tempered connecting rod of engine and manufacturing method of forge pieces

A non-quenching and tempering, engine technology, used in metal rolling, manufacturing tools, metal rolling, etc., can solve the qualified rate of ultrasonic flaw detection, the difficulty of further improvement of low-magnification microstructure, affecting the breaking performance of connecting rods, and the easy segregation of elements. and other problems, to achieve the effect of excellent microstructure, expansion performance and fatigue life of connecting rod, and uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

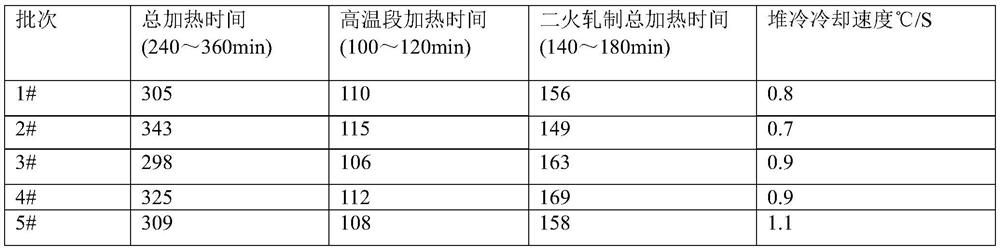

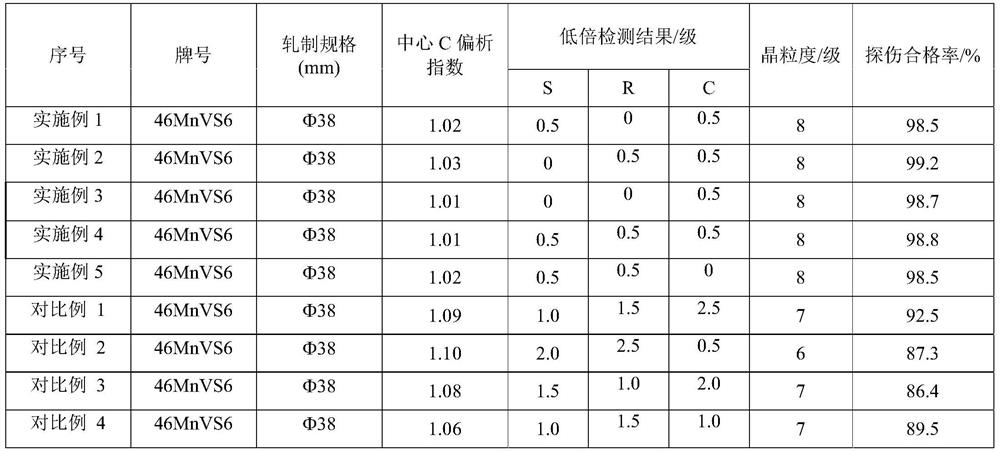

[0030] 46MnVS6 round steel (Φ38.0mm) for engine non-quenched and tempered connecting rod (wt.%: C0.44~0.47%, Si0.52~0.62%, Mn 1.20~1.28%, S 0.045~0.060%, V 0.14 ~0.16%, Nb 0.022~0.038%, Cr 0.18~0.26%, Ni 0.11~0.15%, N 0.012~0.021%) production as an example:

[0031] Steel rolling and forging process: Heating furnace heating - billet rolling - intermediate billet finishing - intermediate billet heating - second fire rolling - cooling - non-destructive testing - blanking - induction heating - forging - controlled cooling.

[0032] 1. Billet heating;

[0033]The continuous casting billet with a section of 280*320mm is heated in an air gas double regenerative heating furnace. The heating temperature is controlled as follows: the furnace temperature of the second heating stage is 1180-1230°C; the furnace temperature of the first heating stage is 950-1050°C; the soaking section is 1190 ~1220°C, control the heating temperature in the preheating section ≤ 850°C (preferably 780~840°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com