A low-resistance connection method for rare earth barium copper oxide superconducting tape

A technology of rare earth barium copper oxide and superconducting tape, which is applied in the direction of connection, connection contact material, line/collector parts, etc., can solve the problems of long welding time, complicated process, increased difficulty and cost, etc., and achieve the connection Low cost, simple operation, and the effect of improving welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

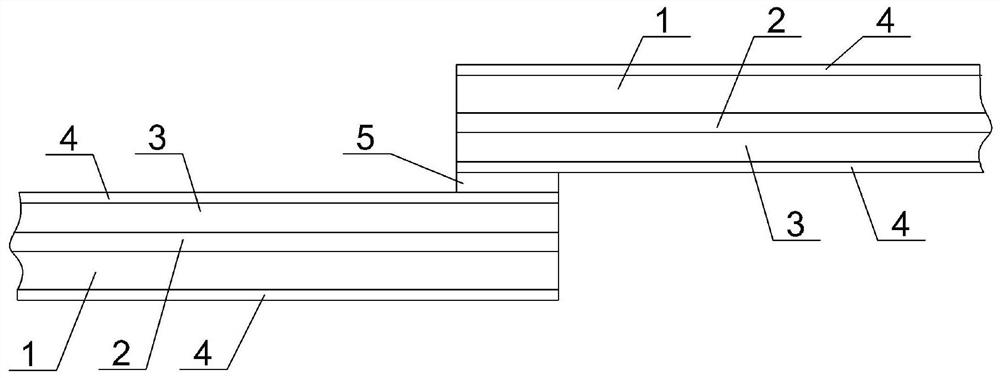

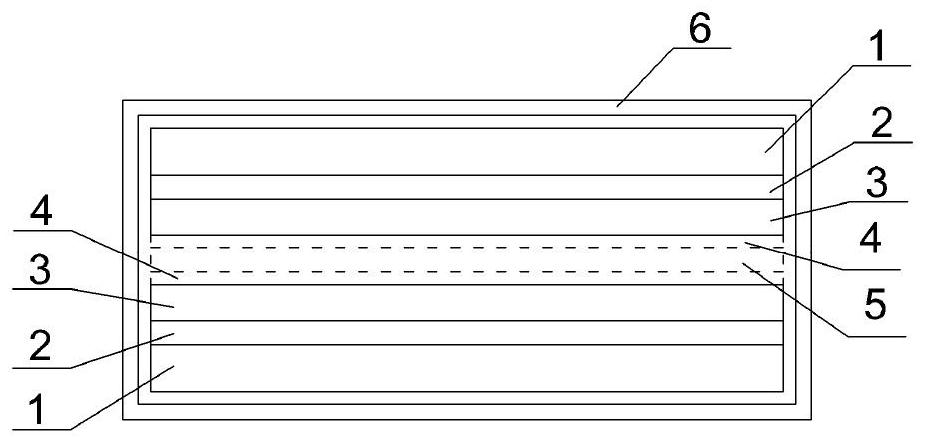

[0029] Figure 1-Figure 2 It is shown that a specific embodiment of the present invention is a low-resistance connection method for rare earth barium copper oxide superconducting strips, the steps of which are:

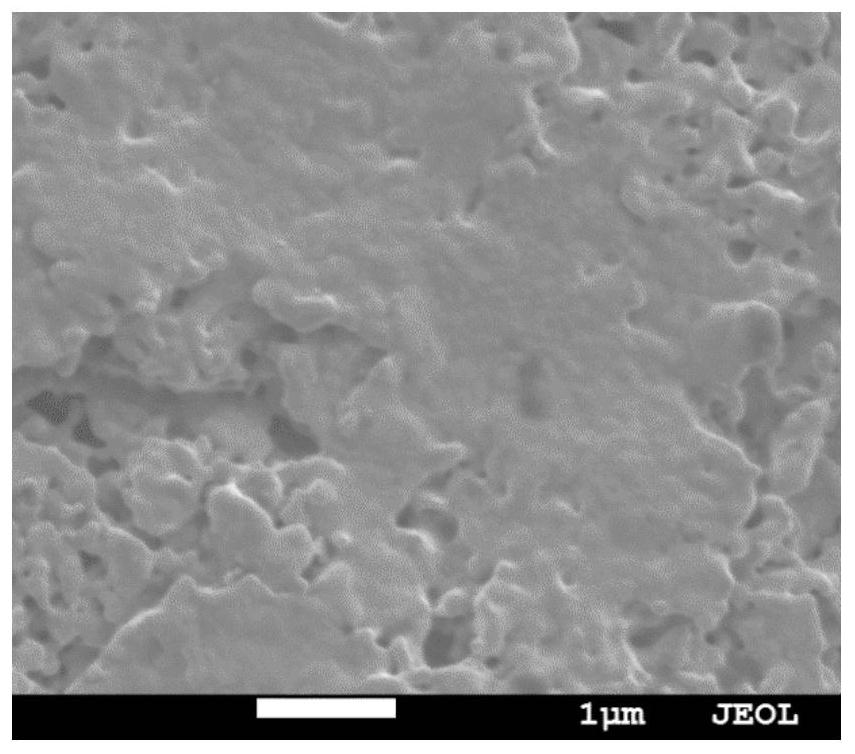

[0030] A. Pretreatment: Delineate the joint area at the ends of the two strips close to the superconducting layer, and apply nano-silver paste on the joint area through the screen printing plate of the screen printing machine; The joint area of the strip is laminated and overlapped to form a weakly connected pre-joint; the strip is a rare earth barium copper oxide superconducting strip with a metal protective layer and only a silver layer;

[0031] Wherein, the starting point of the joint area is the end of the strip, the length is 100 mm, and the width is the same as that of the strip, which is 4 mm.

[0032] Wherein, the specific way of coating nano-silver paste is:

[0033] A1. Wipe the joint area with silver washing water to remove oxides on the surface of the...

Embodiment 2

[0040] A low-resistance connection method for rare-earth barium-copper-oxygen superconducting strips, the steps of which are:

[0041] A. Pretreatment: Delineate the joint area at the ends of the two strips close to the superconducting layer, and apply nano-silver paste on the joint area through the screen printing plate of the screen printing machine; The joint area of the strip is laminated and overlapped to form a weakly connected pre-joint; the strip is a rare earth barium copper oxide superconducting strip with a metal protective layer and only a silver layer;

[0042] Wherein, the starting point of the joint area is the end of the strip, the length is 20 mm, and the width is the same as that of the strip, which is 4 mm.

[0043] Wherein, the specific way of coating nano-silver paste is:

[0044] A1. Wipe the joint area with silver washing water to remove oxides on the surface of the joint area; then use absolute ethanol to clean the remaining silver washing water and ot...

Embodiment 3

[0051] A low-resistance connection method for rare-earth barium-copper-oxygen superconducting strips, the steps of which are:

[0052] A. Pretreatment: Delineate the joint area at the ends of the two strips close to the superconducting layer, and apply nano-silver paste on the joint area through the screen printing plate of the screen printing machine; The joint area of the strip is laminated and overlapped to form a weakly connected pre-joint; the strip is a rare earth barium copper oxide superconducting strip with a metal protective layer and only a silver layer;

[0053] Wherein, the starting point of the joint area is the end of the strip, the length is 10 mm, and the width is the same as that of the strip, which is 4 mm.

[0054] Wherein, the specific way of coating nano-silver paste is:

[0055] A1. Wipe the joint area with silver washing water to remove oxides on the surface of the joint area; then use absolute ethanol to clean the remaining silver washing water and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com