Ceramic coating for power plant boiler heating surface and preparation method thereof

A ceramic coating and ceramic whisker technology, which is applied to the ceramic coating on the heating surface of power plant boilers and its preparation field, can solve the problems of easy cracks on the coating surface and damage to the protective performance, and achieve a dense and smooth coating surface with low equipment requirements , the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037]

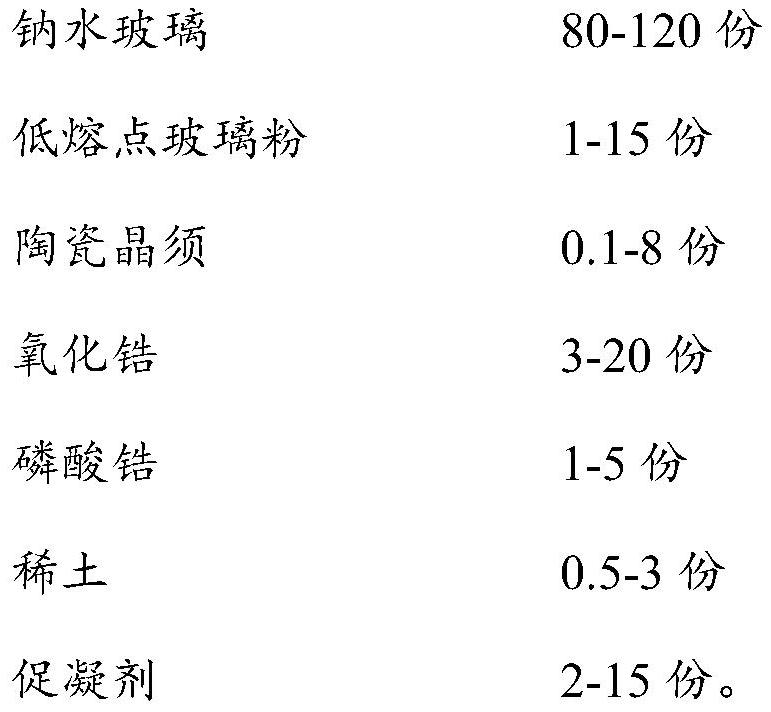

[0038] (1) Weigh low-melting point glass powder, ceramic whiskers, zirconia, zirconium phosphate and rare earth according to the formula, put them in a drying oven, bake at 200°C for 2 hours, and then mix to obtain a mixed powder.

[0039] (2) Add sodium water glass to the mixed powder and mix evenly to obtain ceramic coating.

[0040] The surface of the boiler tube wall is polished and cleaned, and then the prepared ceramic coating is evenly sprayed on the metal surface with an atomizing spray gun, the spraying pressure is 0.8MPa, and the coating thickness is 30-120μm. After the spraying is completed, the coating is naturally dried for 10 hours. After the furnace is turned on, it is solidified with the temperature of the furnace, and the coating does not appear cracks.

[0041] Then, when the boiler was used continuously for 180, 270, and 365 days, the appearance of the furnace tube was observed, as shown in figure 1 It can be seen that it is still as bright as n...

Embodiment 2

[0043]

[0044] (1) Weigh low-melting point glass powder, ceramic whiskers, zirconia, zirconium phosphate and rare earth according to the formula, put them in a drying oven, bake at 200°C for 2 hours, and then mix to obtain a mixed powder.

[0045] (2) Add sodium water glass to the mixed powder obtained in step (1), and mix evenly to obtain a ceramic coating.

[0046] The surface of the boiler tube wall is polished and cleaned, and then the prepared ceramic coating is evenly sprayed on the metal surface with an atomizing spray gun, the spraying pressure is 0.8MPa, and the coating thickness is 30-120μm. After the spraying is completed, the coating is naturally dried for 10 hours. After the furnace is turned on, it is solidified with the temperature of the furnace, and the coating does not appear cracks.

[0047] Then, when the boiler was used continuously for 180, 270, and 365 days, the appearance of the furnace tube was observed, and it was still as bright as new after one ...

Embodiment 3

[0049]

[0050]

[0051] (1) Weigh low-melting point glass powder, ceramic whiskers, zirconia, zirconium phosphate and rare earth according to the formula, put them in a drying oven, bake at 200°C for 2 hours, and then mix to obtain a mixed powder.

[0052] (2) Add sodium water glass to the mixed powder obtained in step (1), and mix evenly to obtain a ceramic coating.

[0053]The surface of the boiler tube wall is polished and cleaned, and then the prepared ceramic coating is evenly sprayed on the metal surface with an atomizing spray gun, the spraying pressure is 0.8MPa, and the coating thickness is 30-120μm. After the spraying is completed, the coating is naturally dried for 10 hours. After the furnace is turned on, it is solidified with the temperature of the furnace, and the coating does not appear cracks.

[0054] Then, when the boiler was used continuously for 180, 270, and 365 days, the appearance of the furnace tube was observed, and it was still as bright as new...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com