Modified waste and old rubber, preparation method thereof and sound insulation mortar

A waste rubber and modification technology, applied in the field of building materials, can solve the problems of no sound insulation, easy to float, no mechanical properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

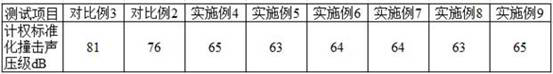

Examples

preparation example Construction

[0030]A method for preparing modified waste rubber includes the following steps:

[0031]Take waste rubber particles with a particle size of 50 mesh to 100 mesh, soak in alkaline solution, take it out and dry, and then freeze at -20℃~-15℃ to prepare rubber particle intermediate;

[0032]The rubber particle intermediate and cement are mixed, and then water is added and placed for 10 to 24 hours to cause the cement to undergo a pre-hydration reaction.

[0033]Understandably, the main components of the waste rubber are natural rubber and synthetic rubber. It can be waste tires or other waste rubber products.

[0034]The mechanism of the present invention to modify waste rubber is as follows:

[0035](1) The particle size of rubber is inversely proportional to its surface area, and rubber is a natural water-repellent material, and the surface is easy to adsorb gas, so as the particle size decreases, the more gaps there are between it and cement hydration products, the The greater the gas effect, the g...

Embodiment 1

[0065]This embodiment provides a modified waste rubber and a preparation method thereof, the steps are as follows:

[0066]Take waste rubber particles with a particle size of 50 mesh to 100 mesh, soak them in NaOH solution for 20 minutes, take them out, dry at 45°C for 20 minutes, return to room temperature, and then freeze at -20°C for 20 minutes to prepare rubber particle intermediates;

[0067]Mix the rubber particle intermediate and cement at a volume ratio of 1:1, stir evenly, then spray water on the surface of the mixture of the two, and leave it for 1 day to pre-hydrate the cement wrapped on the surface of the rubber particle intermediate. Then it was placed in an oven at 60° C. to dry for 4 hours to obtain modified waste rubber.

Embodiment 2

[0069]This embodiment provides a modified waste rubber and a preparation method thereof, the steps are as follows:

[0070]Take waste rubber particles with a particle size of 50 mesh to 100 mesh, soak them in NaOH solution for 25 minutes, take them out, dry at 50°C for 25 minutes, return to room temperature, and freeze at -18°C for 20 minutes to prepare rubber particle intermediates;

[0071]Mix the rubber particle intermediate and cement at a volume ratio of 1.1:1, stir evenly, then spray water to the surface of the mixture of the two, and leave it for 1 day to pre-hydrate the cement wrapped on the surface of the rubber particle intermediate. Then it was placed in an oven at 60° C. to dry for 4 hours to obtain modified waste rubber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com