Treatment method and application of inorganic binder reclaimed sand

A technology of inorganic binder and treatment method, which is used in the cleaning/treatment machinery of casting materials, casting molding equipment, casting molds, etc. problems, to achieve the effect of improving bond strength and reducing process requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

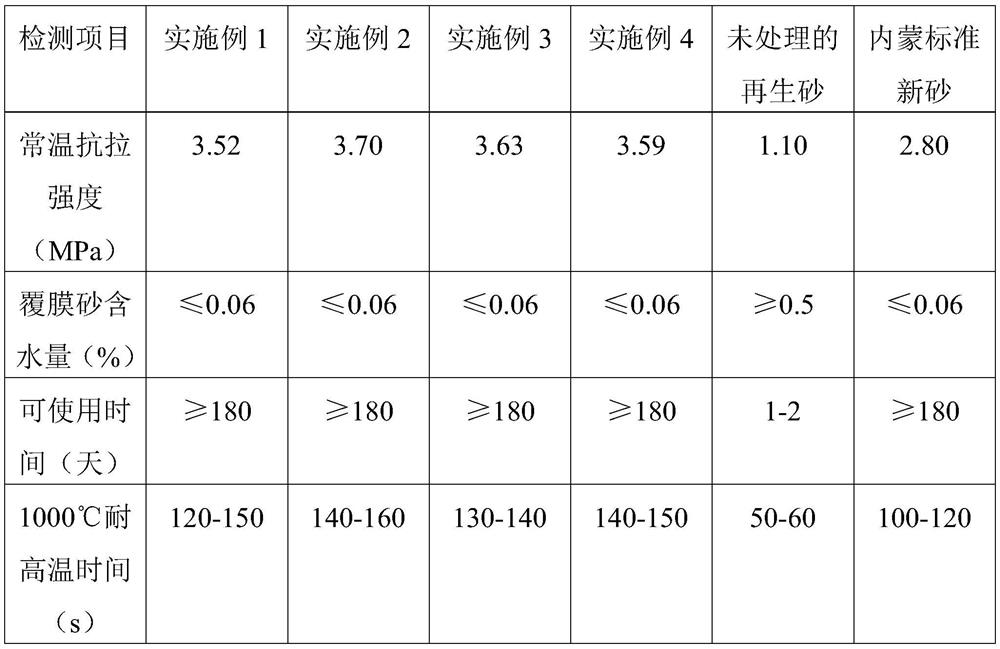

Embodiment 1

[0041] A method for treating reclaimed sand with inorganic binder in this embodiment, stirs regenerated sand with inorganic binder, sintering agent and water evenly, the quality of water is 1% of the mass of sintering agent, and the quality of sintering agent is 1% of the mass of inorganic binder 0.1% of the mass of regenerated sand, the sintering agent includes 70 parts of silicon dioxide powder, 10 parts of sodium oxide, 5 parts of potassium nitrate, and 1 part of carbon, and the reaction is carried out for 10 minutes at a standing temperature of 80 ° C. Under heat treatment, the treated inorganic binder regenerated sand is obtained.

Embodiment 2

[0043] A method for treating reclaimed sand with inorganic binder in this embodiment, stirs regenerated sand with inorganic binder, sintering agent and water evenly, the quality of water is 5.5% of the mass of sintering agent, and the quality of sintering agent is 5.5% of the mass of inorganic binder 2.5% of the mass of regenerated sand, the sintering agent includes 75 parts of silicon dioxide powder, 7.5 parts of sodium oxide, 7.5 parts of potassium sulfate, and 0.75 parts of carbon. The sintering agent is left to stand for 20 minutes, and the reaction temperature is 50°C. heat treatment to obtain the treated inorganic binder regenerated sand.

Embodiment 3

[0045] A method for treating regenerated sand with inorganic binder in this embodiment, stirs regenerated sand with inorganic binder, sintering agent and water evenly, the quality of water is 10% of the mass of sintering agent, and the quality of sintering agent is 10% of the mass of inorganic binder 5% of the mass of regenerated sand, the sintering agent includes 80 parts of silicon dioxide powder, 5 parts of sodium oxide, 10 parts of potassium nitrate, and 0.5 part of carbon. The sintering agent is allowed to stand for 30 minutes and the reaction temperature is 20°C. heat treatment to obtain the treated inorganic binder regenerated sand.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com