A copper wire automatic processing equipment

A processing equipment and copper wire technology, which is applied in the field of copper wire automatic processing equipment, can solve problems such as copper wires that are easy to break, and achieve the effects of reducing breakage, saving resources, and improving the effect of easy breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

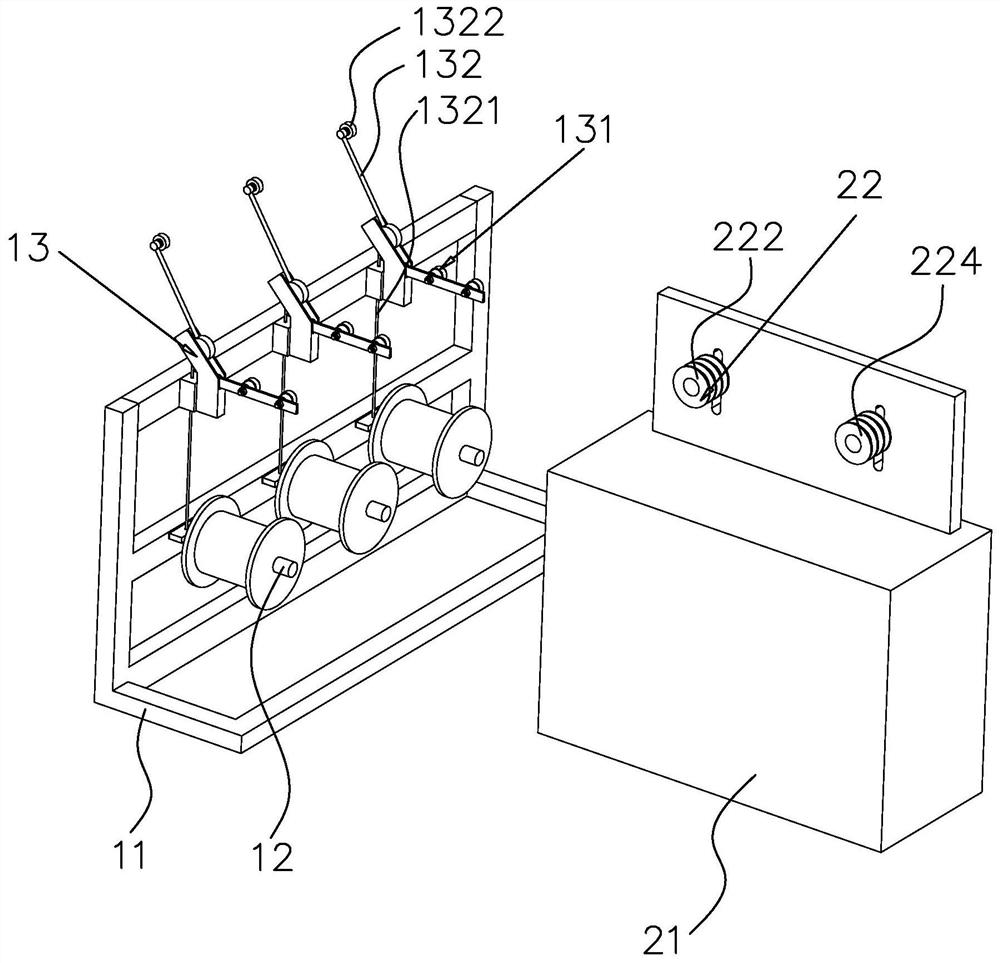

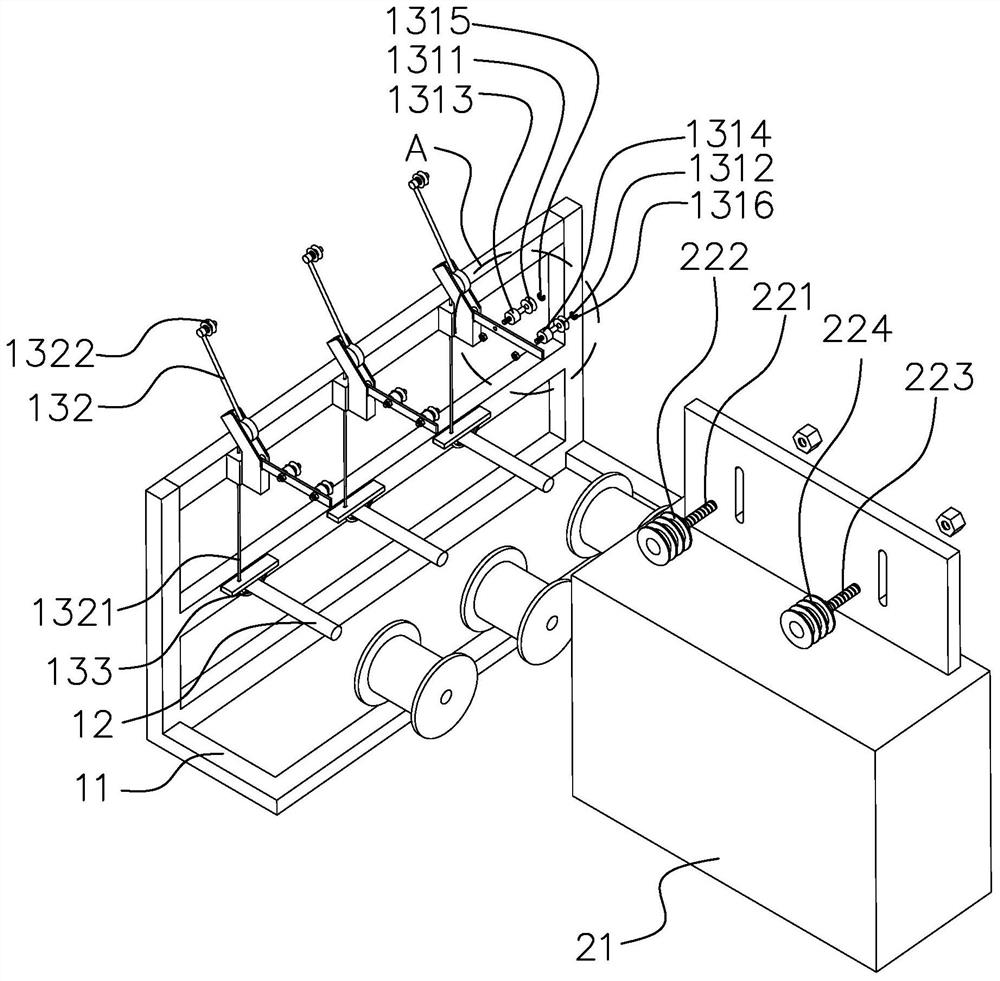

[0039] The following is attached Figure 1-8 The application is described in further detail.

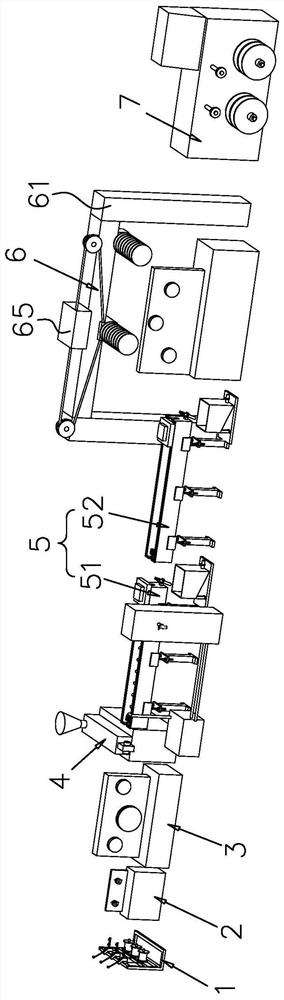

[0040] The embodiment of the present application discloses an automatic copper wire processing equipment. refer to figure 1 The copper wire automatic processing equipment includes a feeding device 1, a first stabilizing device 2 for stabilizing copper wire feeding, a preheating device 3, an extruding device 4, a cooling device 5, a second stabilizing device 6 and a winding device 7 . When the copper wire is processed, the copper wire is fed from the feeding device 1, and then enters the first stabilizing device 2. After the first stabilizing device 2 stabilizes the copper wire, the copper wire enters the preheating device 3 Preheating is carried out in order to facilitate subsequent processing, then the copper wire passes through the extrusion device 4, and the extrusion device 4 will extrude and inject the copper wire, and the extruded copper wire enters the cooling device 5 for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com