A liquid material supply system for suspension cold spraying process

A supply system and suspension technology, applied in the direction of liquid injection devices, injection devices, etc., can solve the problems of insufficient feeding pressure, differences in feeding methods, and the inability to prepare composite coatings or multi-gradient coatings by suspension spraying, so as to improve performance , the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

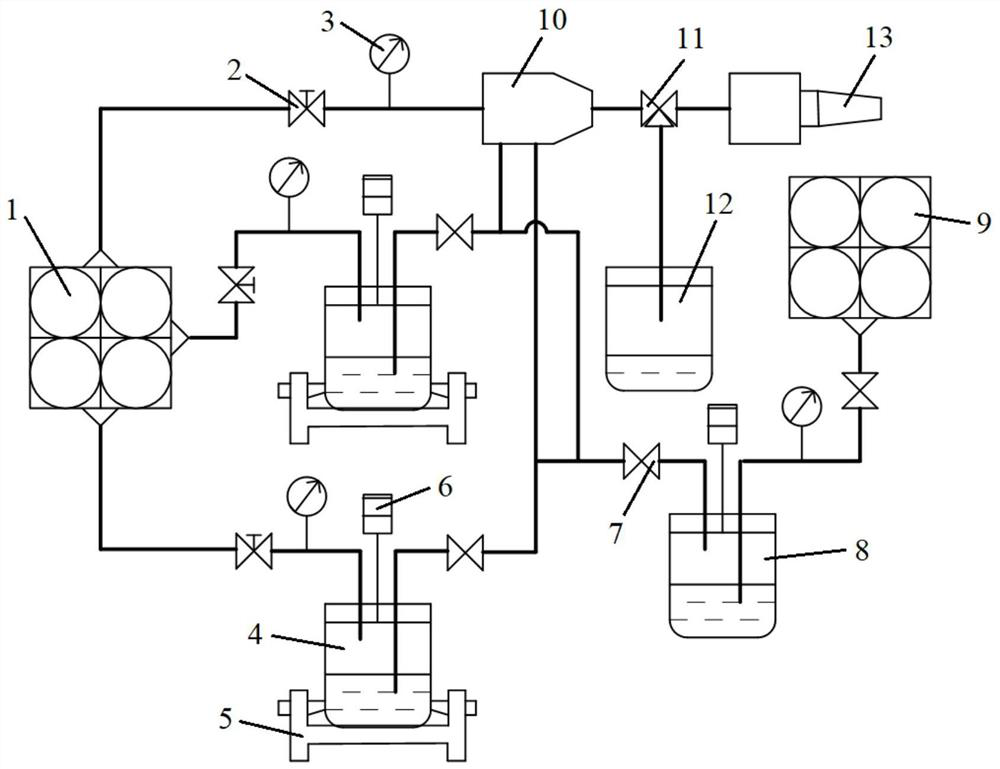

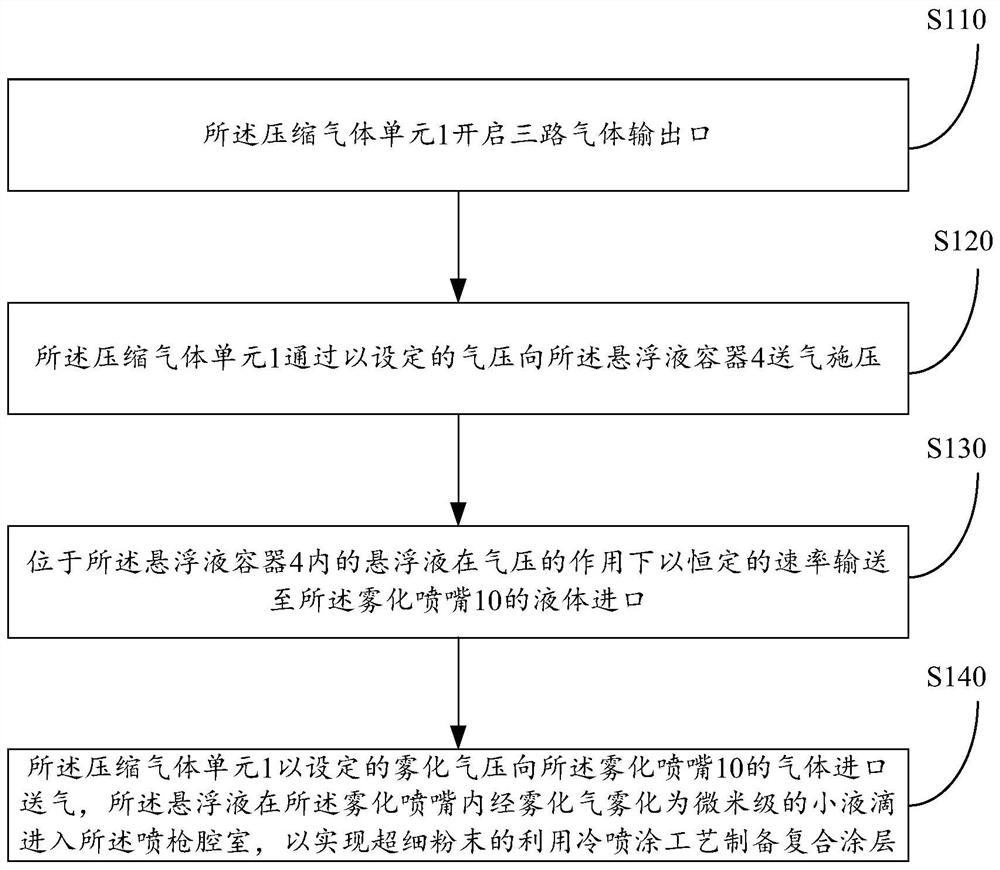

[0037] see figure 1 , is a structural schematic diagram of a liquid material supply system for a suspension cold spraying process provided by an embodiment of the present invention, including a compressed gas unit 1, at least two suspension containers 4, arranged under any one of the suspension containers 4 The oscillating device 5, the atomizing nozzle 10 and the spray gun 13; the compressed gas unit 1 includes at least three gas outlets. The connection relationship among the various components will be described in detail below.

[0038] The first gas output port of the compressed gas unit 1 is connected to the gas inlet of the atomizing nozzle 10 through a gas pipeline, and the remaining gas output ports of the compressed gas unit 1 are connected to any one of the suspension containers 4 respectively. Liquid import.

[0039] An oscillating device 5 is arranged below any one of the suspension containers 4. Since the suspension will produce particle precipitation over time, ...

Embodiment 2

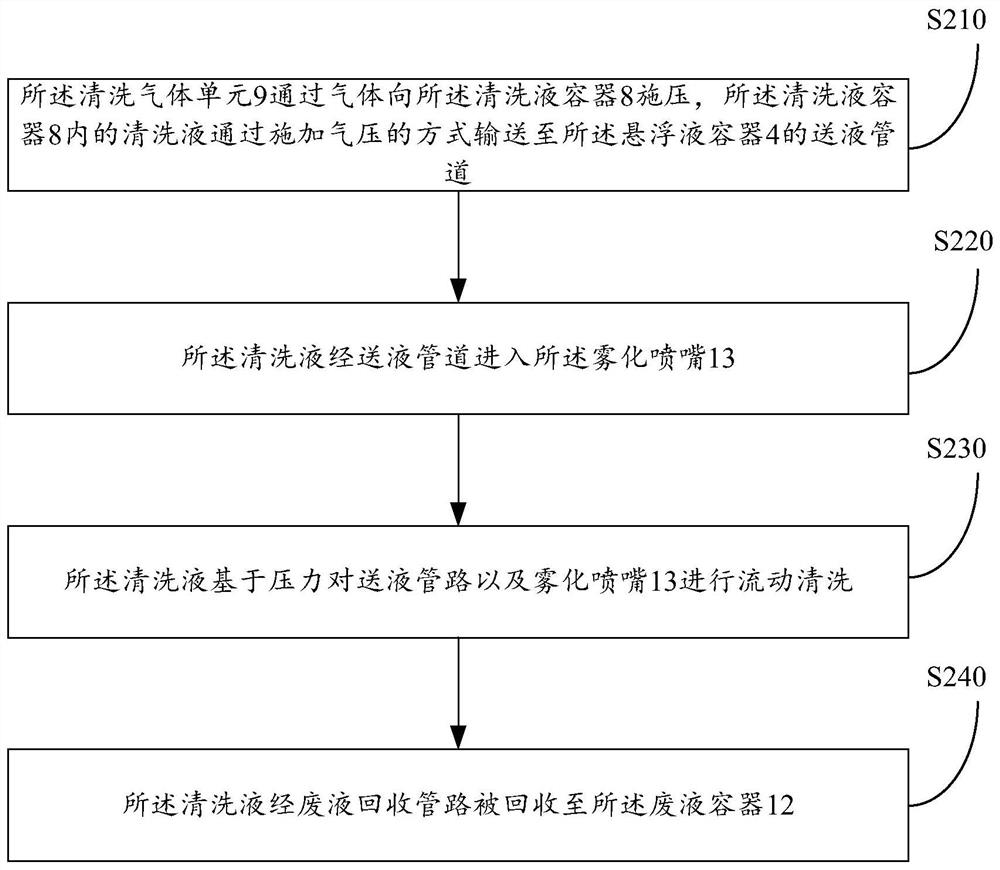

[0064] The liquid material supply system used in the suspension cold spraying process provided in this embodiment is similar to the structure of the above-mentioned embodiment 1, the difference lies in its working mode, which will be described in detail below.

[0065] see Figure 4 , the flow chart of the steps of the liquid material supply system for the suspension cold spraying process provided by Embodiment 2 of the present invention, its working steps are as follows:

[0066] Step S310: the compressed gas unit 1 opens three gas outlets;

[0067] Step S320: the compressed air unit 1 sends air to the two suspension containers 4 at different air pressures to apply pressure;

[0068] Step S330: different suspensions located in the two suspension containers 4 are delivered to the liquid inlet of the atomizing nozzle 10 at different rates under the action of air pressure;

[0069] Step S340: The compressed gas unit 1 sends air to the gas inlet of the atomizing nozzle 10 at th...

Embodiment 3

[0076] The liquid material supply system for the suspension cold spraying process provided in this embodiment is similar to the structure of the above-mentioned embodiment 1, wherein there are M suspension containers, M≥2, and the compressed gas unit includes N-way gas output ports , N≥3, N-M=1, the difference lies in its working mode, the working mode of M=2, N=3 will be described in detail below.

[0077] see Figure 5 , the flow chart of the steps of the liquid material supply system for the suspension cold spraying process provided by Embodiment 3 of the present invention, its working steps are as follows:

[0078] Step S410: the compressed air unit 1 starts two-way air supply;

[0079] Step S420: The compressed gas unit 1 sends air to one of the suspension containers 4 at a set air pressure to apply pressure, so that the suspension located in the suspension container 4 is transported to the suspension container 4 under the action of air pressure. The liquid inlet of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com