Nano-copper toothbrush bristles and technical field of manufacturing method thereof

A manufacturing method and nano-copper technology, applied in the direction of bristles, brushes, household appliances, etc., can solve the problems of fracture and shedding, aggravate tooth decay and inflammation, gum damage, etc., to avoid fracture and shedding, lasting sterilization and antibacterial, The effect of improving cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

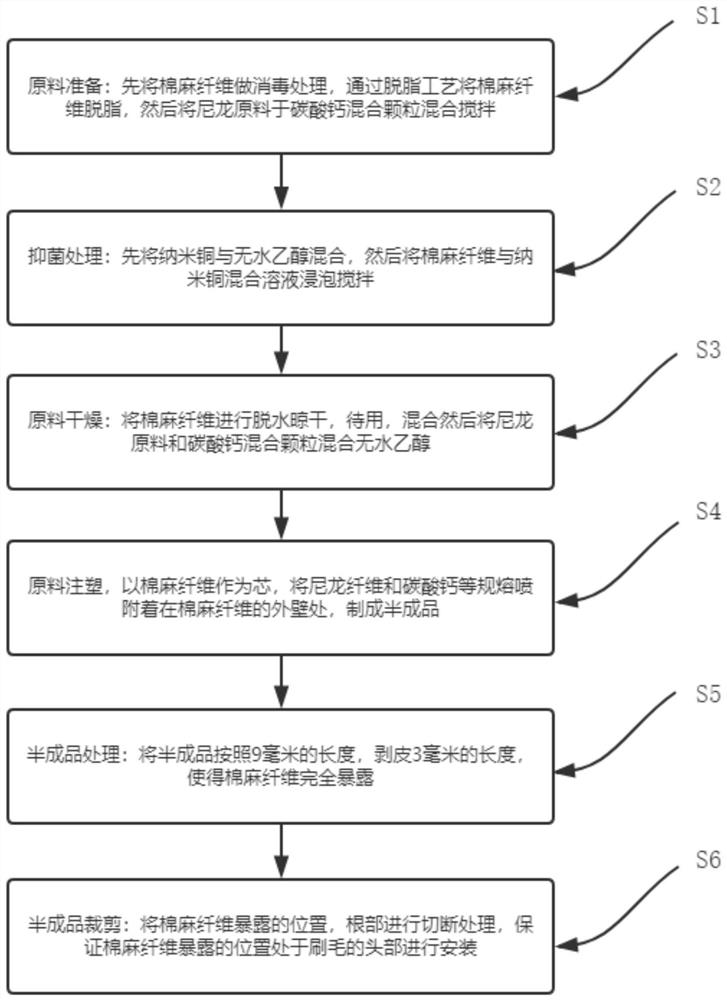

[0026] A nano-copper toothbrush bristle and a manufacturing method thereof, comprising nylon raw material, cotton fiber and calcium carbonate mixed particles, the calcium carbonate mixed particles are superfine light calcium carbonate, bamboo charcoal C active ion, holly AB element, 12 plant glycosides, One or more kinds of pearl calcium powder are mixed in any proportion, the mass ratio of the nylon raw material and calcium carbonate mixed particles is 3.56, and the steps are as follows.

[0027] Step 1. Preparation of raw materials: First, the cotton and linen fibers are sterilized, and the cotton and linen fibers are degreased through a degreasing process, and then the nylon raw materials are mixed with calcium carbonate mixed particles.

[0028] Step 2, antibacterial treatment: firstly mix the nano-copper with absolute ethanol, then soak and stir the mixed solution of cotton fiber and nano-copper.

[0029] Step 3, raw material drying: dehydrate the cotton fiber and dry it ...

Embodiment 2

[0043] A nano-copper toothbrush bristle and a manufacturing method thereof, comprising nylon raw material, cotton fiber and calcium carbonate mixed particles, the calcium carbonate mixed particles are superfine light calcium carbonate, bamboo charcoal C active ion, holly AB element, 12 plant glycosides, One or more kinds of pearl calcium powder are mixed in any proportion, the mass ratio of the nylon raw material and calcium carbonate mixed particles is 5.56, and the steps are as follows.

[0044] Step 1. Preparation of raw materials: First, the cotton and linen fibers are sterilized, and the cotton and linen fibers are degreased through a degreasing process, and then the nylon raw materials are mixed with calcium carbonate mixed particles.

[0045] Step 2, antibacterial treatment: firstly mix the nano-copper with absolute ethanol, then soak and stir the mixed solution of cotton fiber and nano-copper.

[0046] Step 3, raw material drying: dehydrate the cotton fiber and dry it ...

Embodiment 3

[0060] A nano-copper toothbrush bristle and a manufacturing method thereof, comprising nylon raw material, cotton fiber and calcium carbonate mixed particles, the calcium carbonate mixed particles are superfine light calcium carbonate, bamboo charcoal C active ion, holly AB element, 12 plant glycosides, One or more kinds of pearl calcium powder are mixed in any proportion, the mass ratio of the nylon raw material and calcium carbonate mixed particles is 4.56, and the steps are as follows.

[0061] Step 1. Preparation of raw materials: First, the cotton and linen fibers are sterilized, and the cotton and linen fibers are degreased through a degreasing process, and then the nylon raw materials are mixed with calcium carbonate mixed particles.

[0062] Step 2, antibacterial treatment: firstly mix the nano-copper with absolute ethanol, then soak and stir the mixed solution of cotton fiber and nano-copper.

[0063] Step 3, raw material drying: dehydrate the cotton fiber and dry it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com