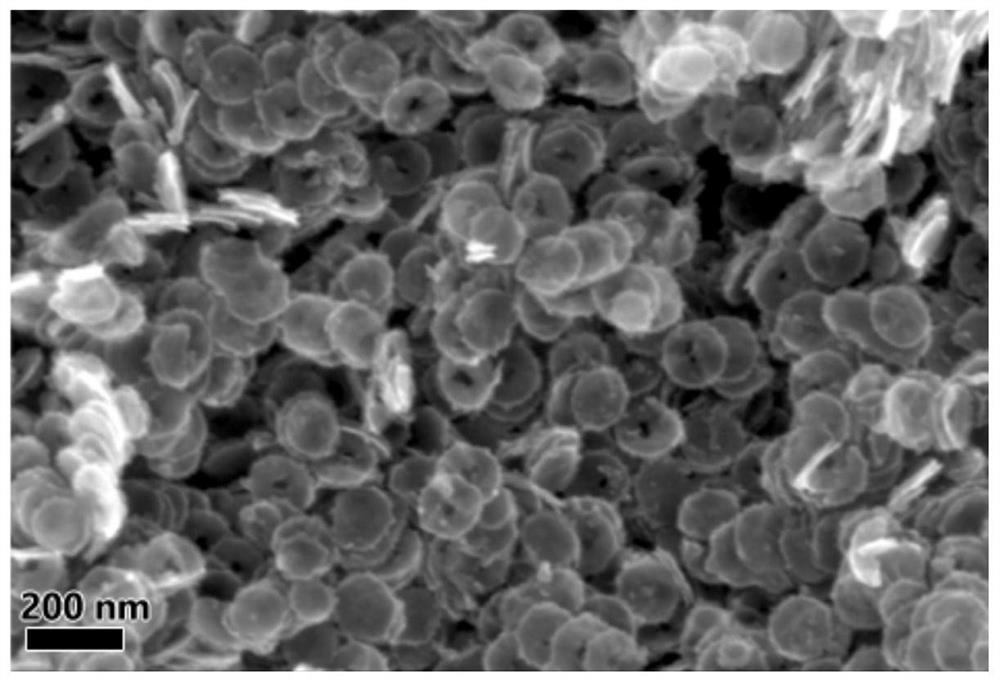

A kind of ultra-thin disc mesoporous carbon material and its preparation method and application

A mesoporous carbon, sheet-like technology, applied in the field of fuel cell electrocatalysis, can solve the problem of low economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

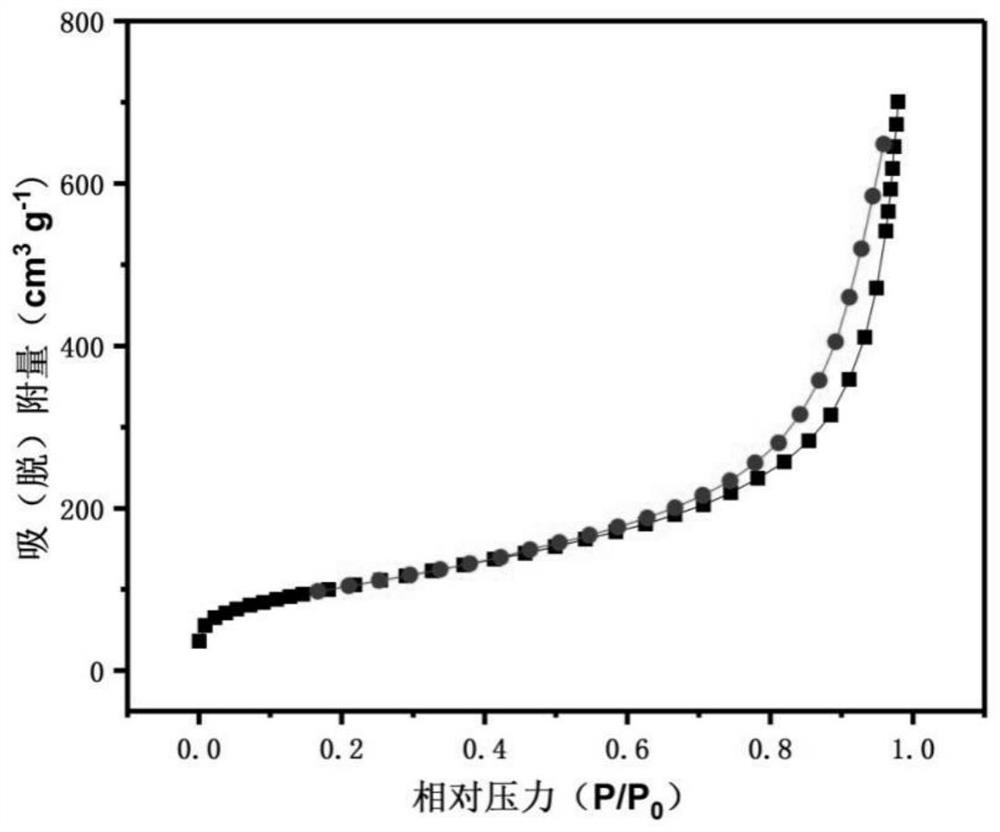

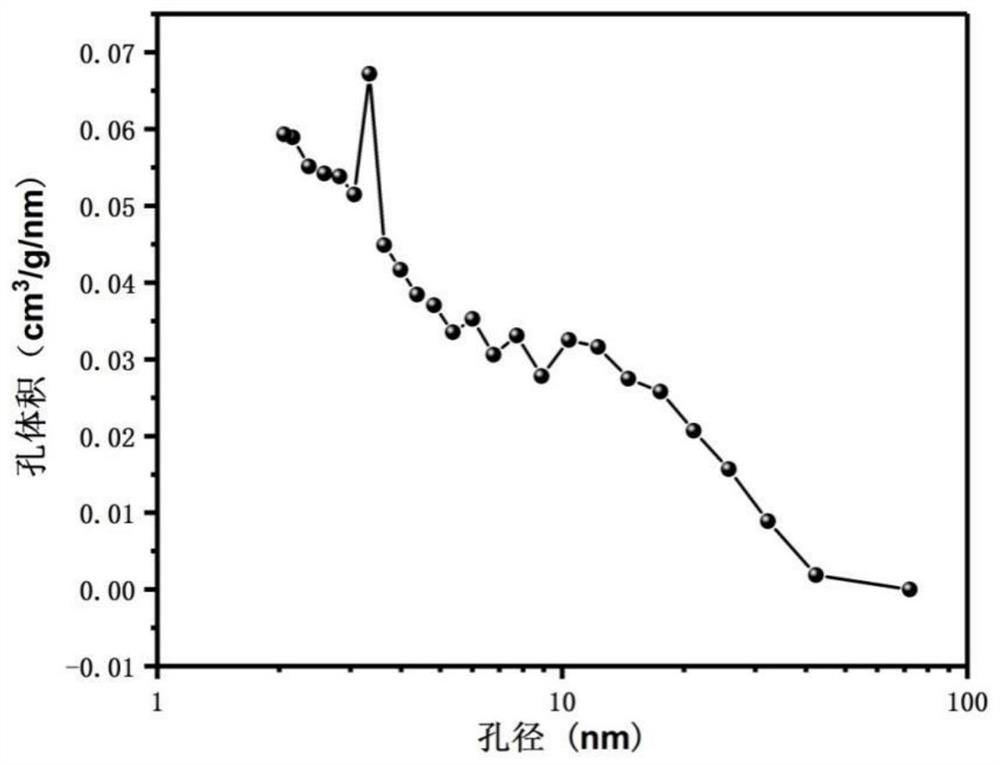

[0044] This embodiment provides a method for preparing an ultra-thin disc-shaped mesoporous carbon material, wherein the preparation method includes the following steps:

[0045] (1) Add 60 mL of absolute ethanol, 30 mL of deionized water and 10 mL of ammonia water into a 100 mL beaker, stir for 10 min, add 10 mL of TEOS, keep the temperature at 60 ° C, and continue the reaction for 3 h.

[0046] The product was centrifuged and washed three times with absolute ethanol, and then dried at 100°C to obtain spherical silica.

[0047] Spherical silica and waste tire pyrolysis oil are fully mixed at a mass ratio of 3:1; in the present embodiment, the waste tire pyrolysis oil is a heavy fraction of waste tire pyrolysis oil, and the weight fraction of waste tire pyrolysis oil Quality distillates are distillate oils with a temperature greater than 350°C.

[0048] (2) Put the mixture in a corundum porcelain boat, put it into a horizontal furnace and pass in argon gas, raise the temperatur...

Embodiment 2

[0056] This embodiment provides a method for preparing an ultra-thin disc-shaped mesoporous carbon material, wherein the preparation method includes the following steps:

[0057] (1) Add 60 mL of absolute ethanol, 30 mL of deionized water and 10 mL of ammonia water into a 100 mL beaker, stir for 10 min, add 10 mL of TEOS, keep the temperature at 60 ° C, and continue the reaction for 3 h.

[0058] The product was centrifuged and washed three times with absolute ethanol, and then dried at 100°C to obtain spherical silica.

[0059] Spherical silica and waste tire pyrolysis oil are fully mixed in a mass ratio of 2:1; in the present embodiment, the waste tire pyrolysis oil is a heavy fraction of waste tire pyrolysis oil, and the weight Quality distillates are distillate oils with a temperature greater than 350°C.

[0060] (2) Put the mixture in a corundum porcelain boat, then put it into a horizontal furnace and pass in argon gas, raise the temperature in the horizontal furnace to...

Embodiment 3

[0063] This embodiment provides a method for preparing an ultra-thin disc-shaped mesoporous carbon material, wherein the preparation method includes the following steps:

[0064] (1) Add 60 mL of absolute ethanol, 30 mL of deionized water and 10 mL of ammonia water into a 100 mL beaker, stir for 10 min, add 10 mL of TEOS, keep the temperature at 60 ° C, and continue the reaction for 3 h.

[0065] The product was centrifuged and washed three times with absolute ethanol, and then dried at 100°C to obtain spherical silica.

[0066] Spherical silica and waste tire pyrolysis oil are fully mixed in a mass ratio of 4:1; in the present embodiment, the waste tire pyrolysis oil is a heavy fraction of waste tire pyrolysis oil, and the weight Quality distillates are distillate oils with a temperature greater than 350°C.

[0067] (2) Put the mixture in a corundum porcelain boat, then put it into a horizontal furnace and pass in argon gas, raise the temperature in the horizontal furnace to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com