Efficient evaporation and filtration process method for kitchen high-concentration wastewater

A process method and technology for concentrated wastewater, applied in filtration treatment, chemical instruments and methods, water/sewage treatment, etc., can solve problems such as inability to completely separate wastewater from oil, distillation equipment easily blocked by impurities, and wastewater corrosion, etc. Service life and distillation effect, convenient secondary recycling, water saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

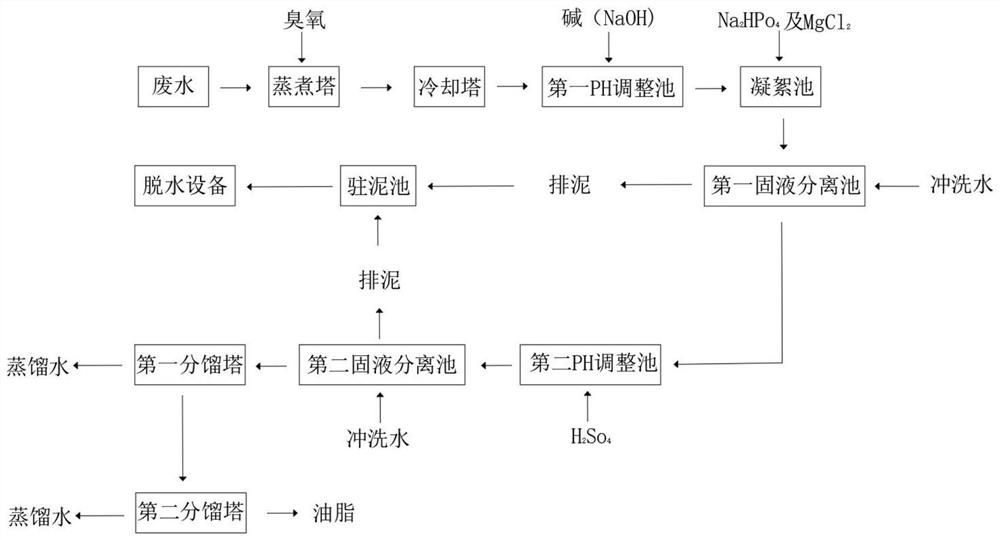

Image

Examples

Embodiment 1

[0028] A high-efficiency evaporation and filtration process method for high-concentration kitchen waste water, comprising the following steps:

[0029] a. Wastewater first enters the cooking tower for high-temperature cooking. During the cooking process, inject ozone into the wastewater in the cooking tower. The dosage of ozone is 1g / L, and the cooking time is 15 minutes. High-temperature sterilization and ozone Sterilization, the waste water after high-temperature cooking enters the cooling tower, and the waste water is cooled and cooled;

[0030] b. The wastewater cooled by the cooling tower is pumped into the first PH adjustment tank, and alkali NaOH is added and stirred and mixed. The reaction time of the wastewater in the first PH adjustment tank is 20 minutes, and the pH value of the wastewater is adjusted for the first time. Secondary adjustment, so that the form of ammonia nitrogen in the wastewater is converted from NH4+ to free ammonia (NH3);

[0031] c. The waste w...

Embodiment 2

[0039] A high-efficiency evaporation and filtration process method for high-concentration kitchen waste water, comprising the following steps:

[0040] a. Wastewater first enters the cooking tower for high-temperature cooking. During the cooking process, inject ozone into the wastewater in the cooking tower. The dosage of ozone is 1g / L, and the cooking time is 20 minutes. High-temperature sterilization and ozone Sterilization, the waste water after high-temperature cooking enters the cooling tower, and the waste water is cooled and cooled;

[0041] b. The wastewater cooled by the cooling tower is pumped into the first pH adjustment tank, and alkali NaOH is added and stirred and mixed. The reaction time of the wastewater in the first pH adjustment tank is 30 minutes, and the pH value of the wastewater is adjusted for the first time. Secondary adjustment, so that the form of ammonia nitrogen in the wastewater is converted from NH4+ to free ammonia (NH3);

[0042]c, the waste wa...

Embodiment 3

[0050] A high-efficiency evaporation and filtration process method for high-concentration kitchen waste water, comprising the following steps:

[0051] a. Wastewater first enters the cooking tower for high-temperature cooking. During the cooking process, inject ozone into the wastewater in the cooking tower. The dosage of ozone is 1g / L, and the cooking time is 25 minutes. High-temperature sterilization and ozone Sterilization, the waste water after high-temperature cooking enters the cooling tower, and the waste water is cooled and cooled;

[0052] b. The wastewater cooled by the cooling tower is pumped into the first PH adjustment tank, and alkali NaOH is added and stirred and mixed. The reaction time of the wastewater in the first PH adjustment tank is 40 minutes, and the pH value of the wastewater is adjusted for the first time. Secondary adjustment, so that the form of ammonia nitrogen in the wastewater is converted from NH4+ to free ammonia (NH3);

[0053] C, the waste w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com