Method for short-process extraction of rubidium chloride from rubidium-containing high-salt brine

A rubidium chloride, short-process technology, applied in chemical instruments and methods, rubidium/cesium/francium compounds, polluted waterways/lakes/ponds/rivers treatment, etc. Small size, serious potassium co-extraction phenomenon, etc., to achieve the effect of reducing the cost of subsequent treatment, reducing the amount of production, and reducing the number of stages of extraction and washing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

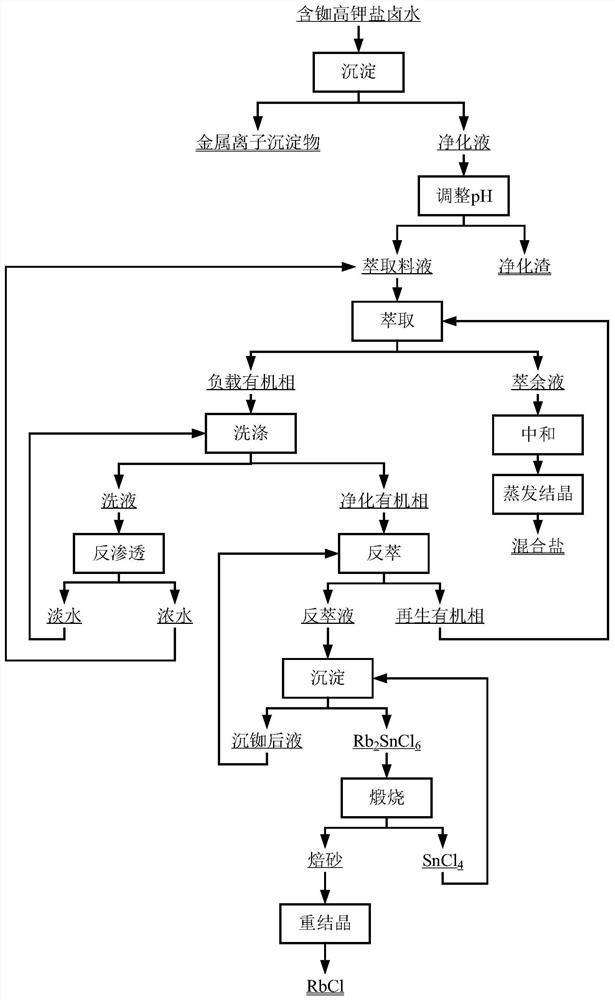

[0046] use figure 1 The process flow shown is to extract rubidium from a certain solid waste leach solution (ie high potassium salt brine containing rubidium), and its main metal components are shown in Table 1.

[0047] Table 1 Main metal components of solid waste leachate

[0048] Element Rb Cs K Na Cu Zn Content (g / L) 3.77 0.41 140.71 47.23 4.78 2.10

[0049] S1: Add NaOH to the solid waste leaching solution, adjust the pH value of the solution to 10, let it stand for 2 hours, precipitate metal ion precipitates, filter and remove the metal ion precipitates, and obtain a purified solution;

[0050] S2: adding NaOH to the purification solution obtained in step S1, adjusting the pH value of the solution to 13.5, and filtering after standing for 2 hours to obtain the extraction material liquid and the purification residue;

[0051] S3: performing extraction-washing-reverse osmosis-back-extraction treatment on the extraction liquid obtained ...

Embodiment 2

[0063] use figure 1 The process flow shown is to extract rubidium in the leaching solution of a certain rubidium-containing ore sinter (ie high-potassium salt brine containing rubidium), and its main metal components are shown in Table 4.

[0064] Table 4 Main metal components of rubidium-containing ore sinter leachate

[0065] Element Rb Cs K Na Cu Zn Pb Content (g / L) 1.74 0.005 88.21 13.26 1.34 8.72 1.11

[0066] S1: adding NaOH to the leaching solution of rubidium-containing ore sinter, adjusting the pH value of the solution to 10, standing for 2 hours, depositing metal ion precipitates, filtering and removing the metal ion precipitates, and obtaining a purified solution;

[0067] S2: adding NaOH to the purification solution obtained in step S1, adjusting the pH value of the solution to 13.5, and filtering after standing for 2 hours to obtain the extraction material liquid and the purification residue;

[0068] S3: performing extract...

Embodiment 3

[0080] use figure 1 The process flow shown is to extract rubidium in a simulated rubidium-containing salt lake water (ie, rubidium-containing high-potassium salt brine), and its main metal components are shown in Table 7.

[0081] Table 7 The main metal components of simulated rubidium-containing salt lake water

[0082] Element Rb Cs K Na Li Mg Content (g / L) 0.21 0.002 27.72 96.95 6.85 28.38

[0083] S1: adding NaOH to the leaching solution of rubidium-containing ore sinter, adjusting the pH value of the solution to 10, standing for 2 hours, depositing metal ion precipitates, filtering and removing the metal ion precipitates, and obtaining a purified solution;

[0084] S2: adding NaOH to the purification solution obtained in step S1, adjusting the pH value of the solution to 13.5, and filtering after standing for 2 hours to obtain the extraction material liquid and the purification residue;

[0085] S3: performing extraction-washing-rever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com