Printing method replacing PP anti-scratch matt film coated on surface with connecting line printing aqueous lacquer

A printing method and connection technology, which is applied in printing, copying/marking methods, coatings, etc., can solve problems such as environmental protection, and achieve strong adhesion, excellent performance in alcohol solvent resistance, and good adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] An embodiment of the present invention provides a printing method for in-line printing with water and oil instead of a PP anti-scratch matte film on the surface, comprising the following steps:

[0027] S100: Prepare a folding-resistant primer that meets printing requirements;

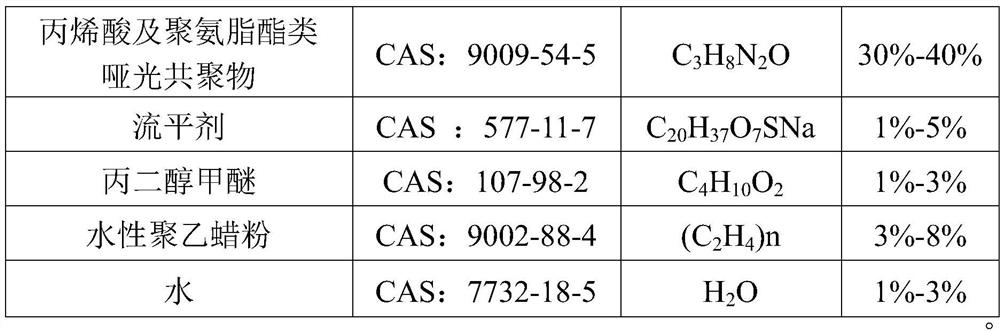

[0028] S200: Prepare wear-resistant surface oil that meets printing requirements;

[0029] S300: In-line printing oiling on a printing machine equipped with two oiling seats, so that the folding-resistant base oil and wear-resistant top oil are superimposed and covered on the surface of colored paper ink.

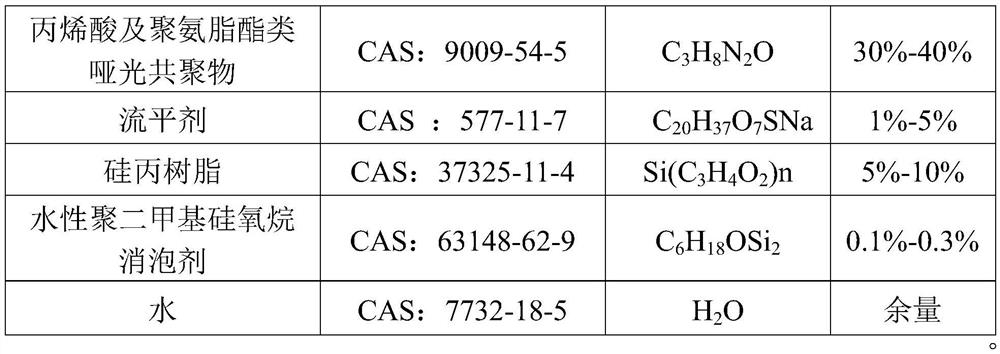

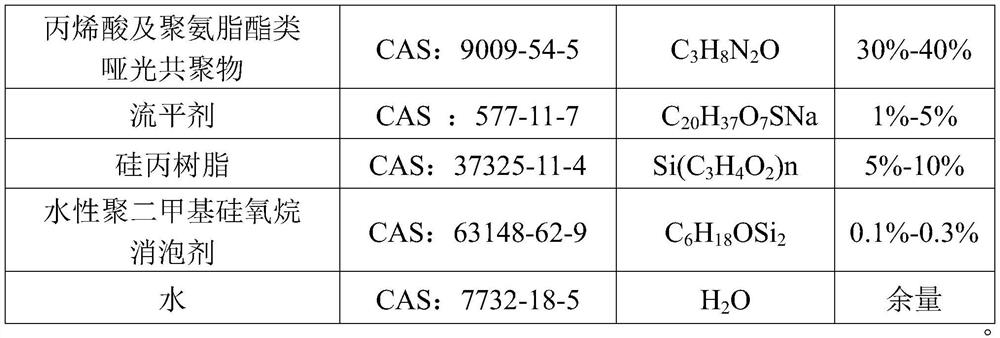

[0030] In this embodiment, in the step S100, the anti-folding base oil is composed of the following raw materials in terms of weight percentage: 30%-40% of acrylic acid and polyurethane ester matte copolymer, 1% of leveling agent -5%, silicone acrylic resin 5%-10%, water-based polydimethylsiloxane defoamer 0.1%-0.3%, and the balance is water.

[0031] Wherein, the content of the acrylic aci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com