Environment-friendly garbage can production process

A production process and technology of trash cans, which are applied in the coating process of metal materials, devices for coating liquid on the surface, special surfaces, etc., can solve the problem of shortening the service life of environmental protection trash cans, affecting the aesthetics of environmental protection trash cans, and color trash cans The surface is easy to fade and other problems, to achieve the effect of good surface finish, smooth surface, easy to clean, and not easy to fade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

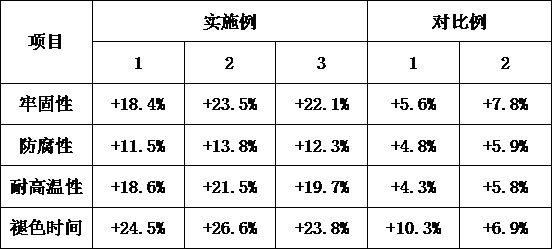

Examples

Embodiment 1

[0024] A kind of production technology of environment-friendly dustbin that the present invention proposes, comprises the following steps:

[0025] S1. Production of the basic frame: using galvanized steel sheets as raw materials, using laser cutting technology, bending and stamping one-time molding to obtain the basic frame of the environmental protection trash can;

[0026] S2, surface treatment of the basic frame: the basic frame of the environmental protection garbage bin obtained in step S1 is surface treated, and the specific steps are as follows:

[0027] A. Degreasing: Use a cotton cloth soaked in ethanol to clean the floating dust on the surface of the basic frame, spray the compound degreasing agent on the surface of the basic frame by spraying, send it into a heating room with a temperature of 52°C, and keep it for 5 minutes. Remove it from the heating chamber and rinse it with clean water. The compound degreasing agent is compounded by absolute ethanol, dioctyl sod...

Embodiment 2

[0035] A kind of production technology of environment-friendly dustbin that the present invention proposes, comprises the following steps:

[0036] S1. Production of the basic frame: using galvanized steel sheets as raw materials, using laser cutting technology, bending and stamping one-time molding to obtain the basic frame of the environmental protection trash can;

[0037] S2, surface treatment of the basic frame: the basic frame of the environmental protection garbage bin obtained in step S1 is surface treated, and the specific steps are as follows:

[0038] A. Degreasing: Use cotton cloth soaked in ethanol to clean the floating dust on the surface of the basic frame, spray the compound degreasing agent on the surface of the basic frame by spraying, send it into a heating room with a temperature of 50°C, and keep it for 8 minutes. Remove it from the heating chamber and rinse it with clean water. The compound degreasing agent is compounded by absolute ethanol, dioctyl sodiu...

Embodiment 3

[0046] A kind of production technology of environment-friendly dustbin that the present invention proposes, comprises the following steps:

[0047] S1. Production of the basic frame: using galvanized steel sheets as raw materials, using laser cutting technology, bending and stamping one-time molding to obtain the basic frame of the environmental protection trash can;

[0048] S2, surface treatment of the basic frame: the basic frame of the environmental protection garbage bin obtained in step S1 is surface treated, and the specific steps are as follows:

[0049] A. Degreasing: Use a cotton cloth soaked in ethanol to clean the floating dust on the surface of the basic frame, spray the compound degreasing agent on the surface of the basic frame by spraying, send it into a heating room with a temperature of 46°C, and keep it for 10 minutes. Remove it from the heating chamber and rinse it with clean water. The compound degreasing agent is compounded by absolute ethanol, dioctyl so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com