Imaginary powder type umbrella face fabric coating and coating method thereof

A technology for fabrics and umbrellas, applied in coatings, textiles, papermaking, fiber processing, etc., can solve problems such as easy to produce dark lines, effect effects, and easy to produce creases, etc., to achieve bright colors and good UV protection effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment one, the coating of polyester plain spinning class umbrella cloth

[0018] After dissolving 22% (weight ratio, the same below) of the illusion powder with toluene, add 58% of PA glue (polyacrylate), and stir evenly; then add 2% of diisocyanate, 1% of chlorinated paraffin and toluene solvent in sequence, And make the total amount of solvent be controlled at 17%. Stir evenly to form spare glue X1; repeat the above steps to prepare spare glue X2.

[0019] Place the gray cloth coated with PA glue on the machine table, adjust the scraper to an appropriate height, and then apply the coating glue X1 on the gray cloth, control the temperature between 120-130°C, and apply the coating glue X2 after drying Coat the upper fabric, control the temperature at 135-145°C, and control the speed at 45-55m / min.

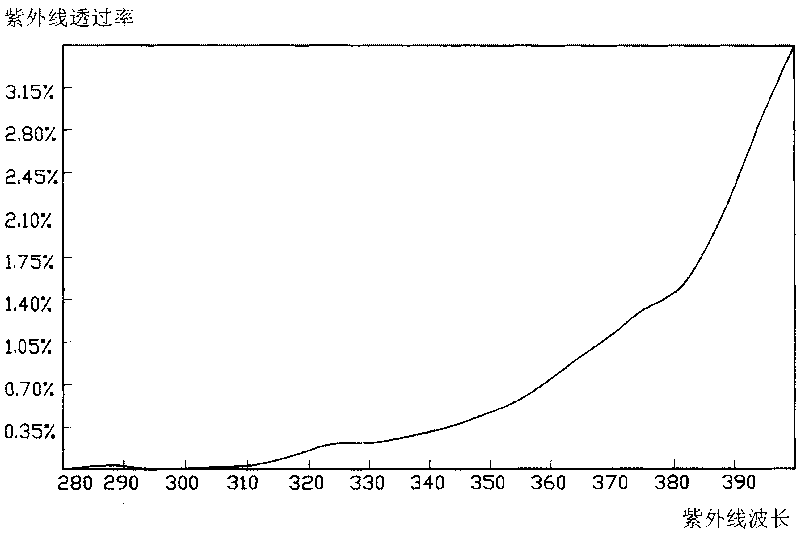

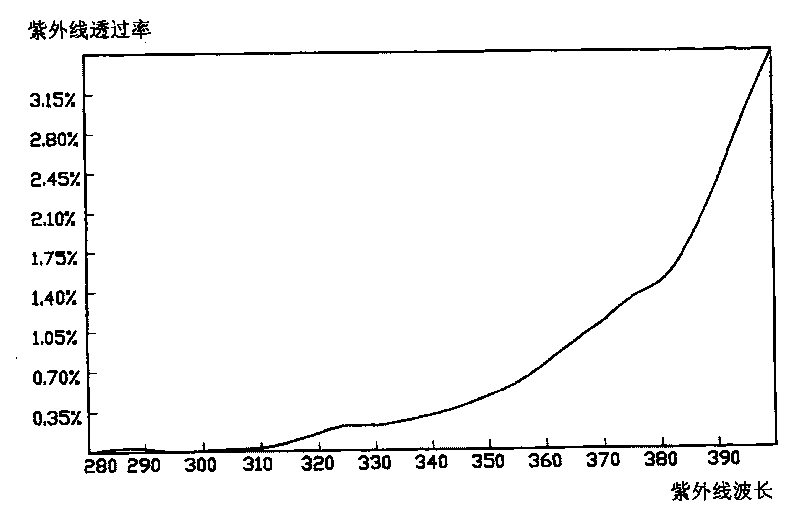

[0020] The coated fabric was tested with the HB902 anti-ultraviolet penetration and sun protection tester according to the national standard GB / T18830. The measured r...

Embodiment 2

[0023] Repeat embodiment one, and each component is prepared by following weight ratio:

[0024] Symphony powder 25%, PA glue 55%, diisocyanate 3%, chlorinated paraffin 1.2%, solvent 15.8%.

Embodiment 3

[0026] Repeat embodiment one, and each component is prepared by following weight ratio:

[0027] Symphony powder 20%, PA glue 60%, diisocyanate 1%, chlorinated paraffin 0.5%, solvent 18.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com