Antibacterial dental cross-scale reinforced resin matrix composite material and its preparation method

A technology for reinforcing resin-based and composite materials, which is applied in dental preparations, dentistry, and dental prostheses. It can solve problems such as lack of antibacterial properties, achieve good biological safety, resist stress on piles, and reduce the probability of fracture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1 Preparation of cross-scale reinforcement

[0041] (1) Fiber decoating: Purify 2m PBO fibers with 200 mL of a mixed solution of ethanol and acetone (volume ratio 1:1) in a Soxhlet extractor for 24 hours to remove low-molecular polymers and pollutants on the PBO surface. Then rinse with 200mL deionized water 5 times for later use to obtain decoated PBO fibers (D-PBO). D-PBO was the control group.

[0042] (2) Oxidation treatment: Immerse the decoated PBO fiber in 60% sulfuric acid, oxidize its surface at room temperature for 4 hours, rinse it repeatedly with deionized water until neutral, and bake it at 100 ° C. Dry for later use to obtain oxidized PBO fibers (O-PBO).

[0043] (3) Carboxylation treatment: Add 12g of sodium hydroxide to 100mL of water to dissolve, then put O-PBO into it, after ultrasonic oscillation for 30min, weigh 10g of chloroacetic acid and add it to the above solution, and then dry it for later use after ultrasonication for 3h to obtain S...

Embodiment 2

[0048] Example 2 Construction of mechanical model of cross-scale reinforced monofilament and evaluation of interface binding performance

[0049] (1) The preparation of the cross-scale reinforcement is the same as in Example 1.

[0050] (2) Construction of monofilament mechanical model and measurement of interfacial bonding properties of monofilament-resin composites

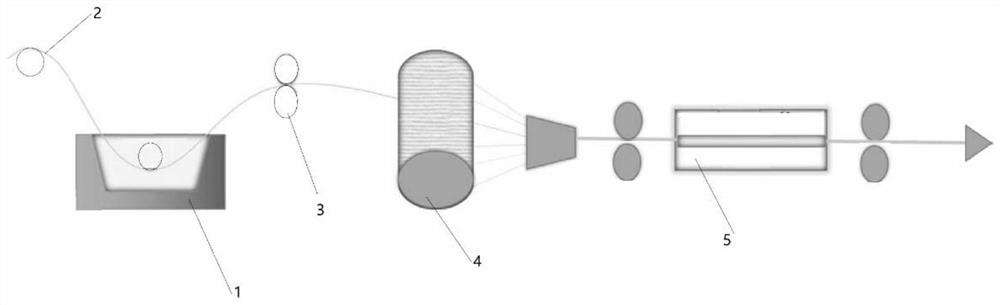

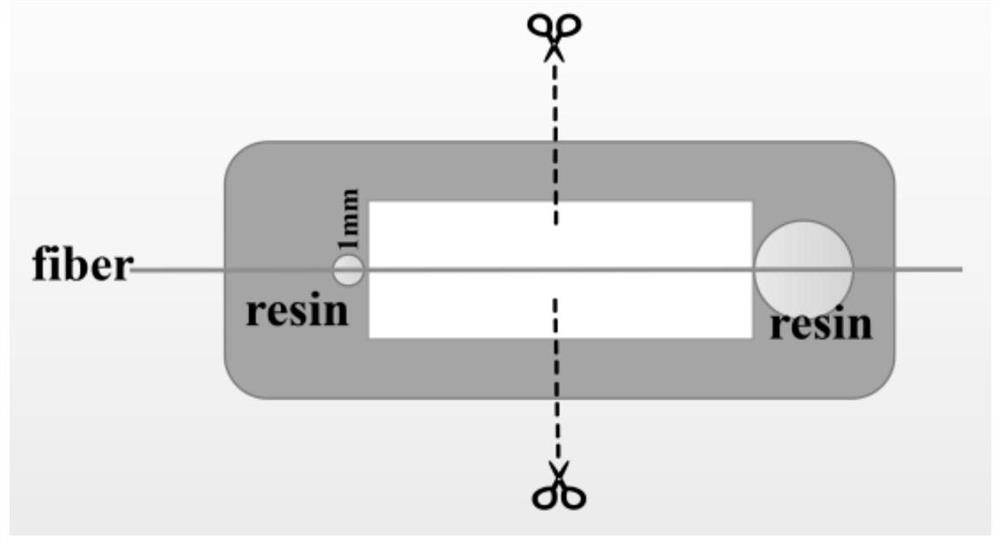

[0051] The fiber-resin bonding properties were analyzed by a single-filament pull-out test to determine the interfacial shear strength of the single-fiber-resin composites. During the test, the pull-out rate is 0.5 μm / s, measure and record the maximum debonding force, and end the test when the maximum debonding force appears. The schematic diagram of the specific sample preparation process is shown in figure 1 .

[0052] Each group of cross-scale reinforcement phases was divided into two groups, and two kinds of resin matrices were selected to prepare monofilament pull-out test samples, respectively: (1) pure...

Embodiment 3

[0064] Example 3: Preparation of Cross-Scale Reinforced Composite Materials

[0065] (1) Preparation of cross-scale reinforcement (same as Example 1)

[0066] (2) Molding and processing of composite materials

[0067] A) Preparation of resin matrix glue: a total of two resin matrix glues are prepared for use, including Bis-GMA pure resin matrix glue without adding zinc oxide nanoparticles and added with the selected mass ratio (1.0wt%) Bis-GMA resin matrix glue of zinc oxide nanoparticles. According to Bis-GMA:TEGDMA=1:1 ratio, prepare a total of 198g of resin glue, avoid light and stir evenly for 30min, add zinc oxide nanoparticles with a mass ratio of 0.0% and 1.0% respectively, and mix for 30min; finally add photoinitiator 0.2g of CQ and 0.8g of DMAEMA (, mixed for 30min and placed in a vacuum oven at room temperature for 2h of degassing. Stir well and keep away from light for later use.

[0068] B) Fiber prepreg preparation: figure 1 Schematic diagram of the composite ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com