Sealing tool and system for sealing detection of sealed container

A closed container and seal detection technology, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, and by detecting the appearance of fluid at the leakage point, can solve the problem of misjudgment of closed containers as defective products and reduce the yield rate of sealing tools Eliminate the manufacturing cost of airtight containers and other issues, and achieve the effects of easy assembly, compact structure, safe and reliable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

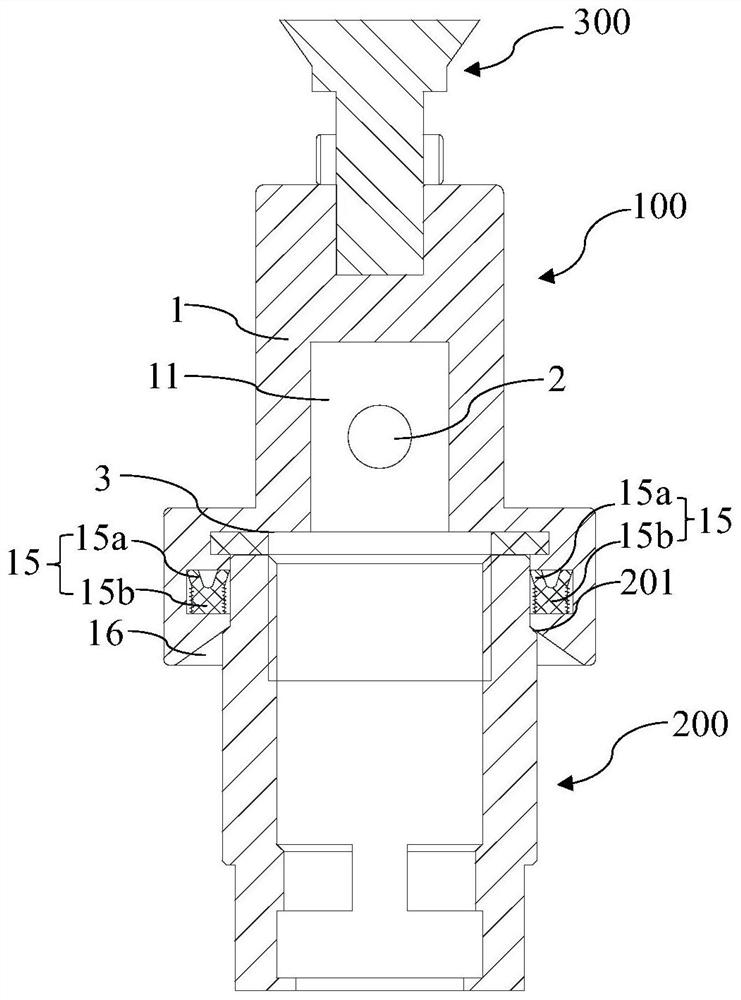

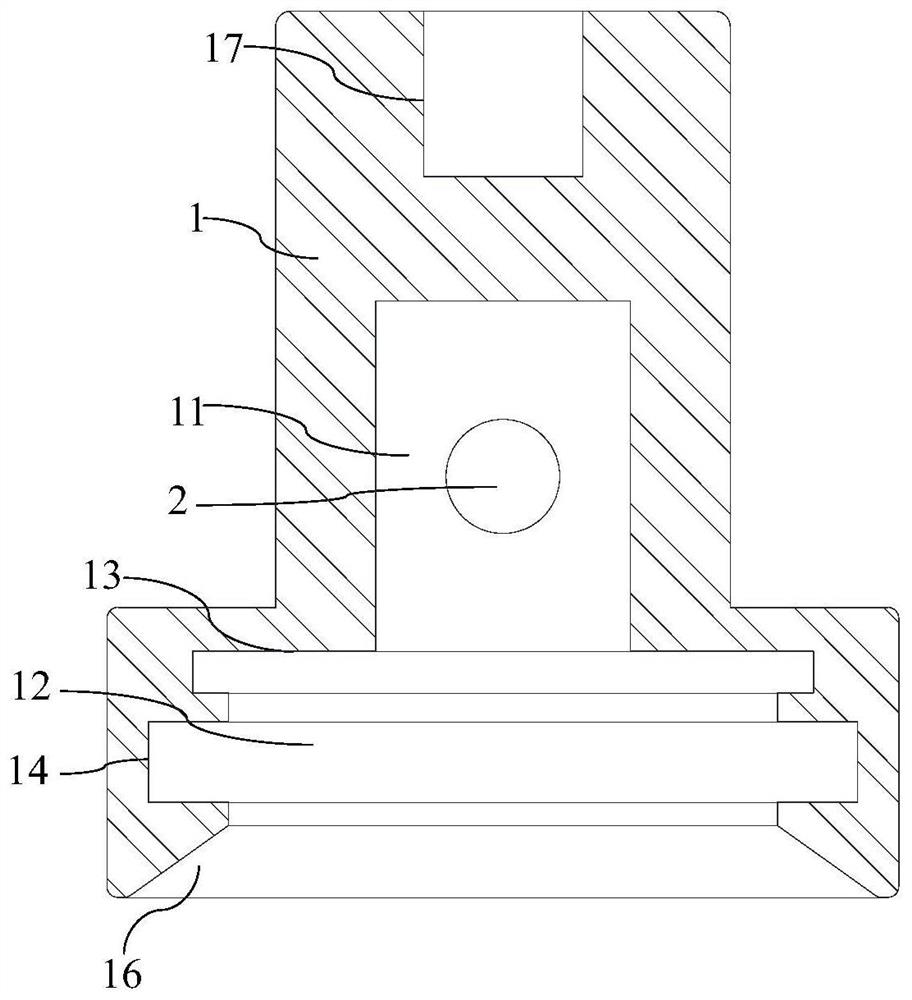

[0020]The present invention will be further described below in conjunction with the drawings.

[0021]figure 1 It is a cross-sectional view of the sealing tool of the embodiment of the present invention in use.figure 2forfigure 1 A cross-sectional view of the tool body of the sealing tool shown. Such asfigure 1 withfigure 2As shown, the sealing tool 100 can be driven by the driving device 300 to be installed on the joint 200 of the closed container, and assist the inflator to perform seal detection on the closed container immersed in liquid. Among them, the sealed container is preferably but not limited to a water tank. The sealing tool 100 mainly includes a tool body 1, an air injection port 2 and a sealing gasket 3. The tool body 1 is used to connect with the driving device 300 and includes a small diameter cavity 11 and a large diameter cavity 12, and an annular plane 13 formed between the small diameter cavity 11 and the large diameter cavity 12. The gas injection port 2 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com