Automobile headlamp

A technology for automobile headlights and high beams, which is applied to headlights, motor vehicles, road vehicles, etc., can solve problems such as affecting the heat dissipation effect of the light source, reducing the photoelectric efficiency of the light source, and failing to achieve ultra-high beam lighting requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

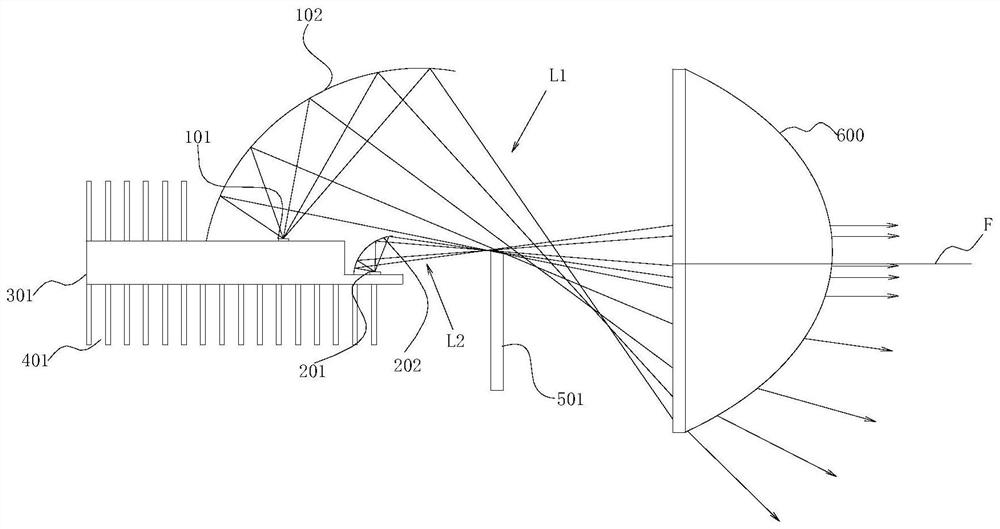

[0039] Such as figure 1 As shown, Embodiment 1 provides an automobile headlamp, including a heat dissipation substrate 301 , a low beam incident optical system, a high beam incident optical system, a light output device 600 , a far and low beam conversion device 501 , and a heat dissipation fin 401 .

[0040] In order to facilitate the understanding of the automobile headlamp provided in Embodiment 1, its application process will be described below first. When the automobile headlamp is in use, the low-beam incident optical system and the high-beam incident optical system are always on. Both the low beam L1 generated by the low beam incident optical system and the high beam L2 produced by the high beam incident optical system are emitted by the light output device 600 . The far and near light switching in Embodiment 1 is realized by the far and near light conversion device 501 . When low beam lighting is required, the low beam incident optical system generates low beam L1 an...

Embodiment 2

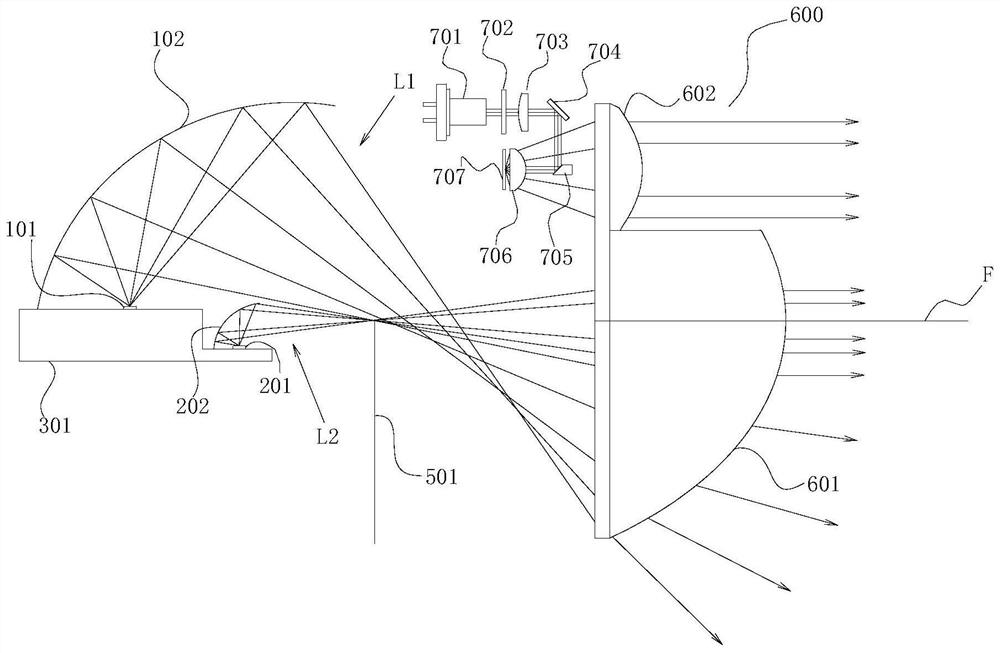

[0050] Such as figure 2 As shown, the present embodiment 2 provides an automobile headlight, which is improved on the scheme of embodiment 1. The automobile headlamp includes a heat dissipation substrate 301 , a low beam incident optical system, a high beam incident optical system, a light output device 600 , and a high and low beam conversion device 501 . In order to achieve ultra-long-distance lighting effects, an auxiliary high-beam incident optical system is added in Embodiment 2 of the present application.

[0051] Wherein, the light output device 600 includes a first light output lens 601 and a second light output lens 602, and the first light output lens 601 is located below the second light output lens 602; the first light area and the second light area It is located on the first light output lens 601, and the area occupied by the first light area and the second light area is formed after the first light output lens 601 removes part of its upper end structure; the th...

Embodiment 3

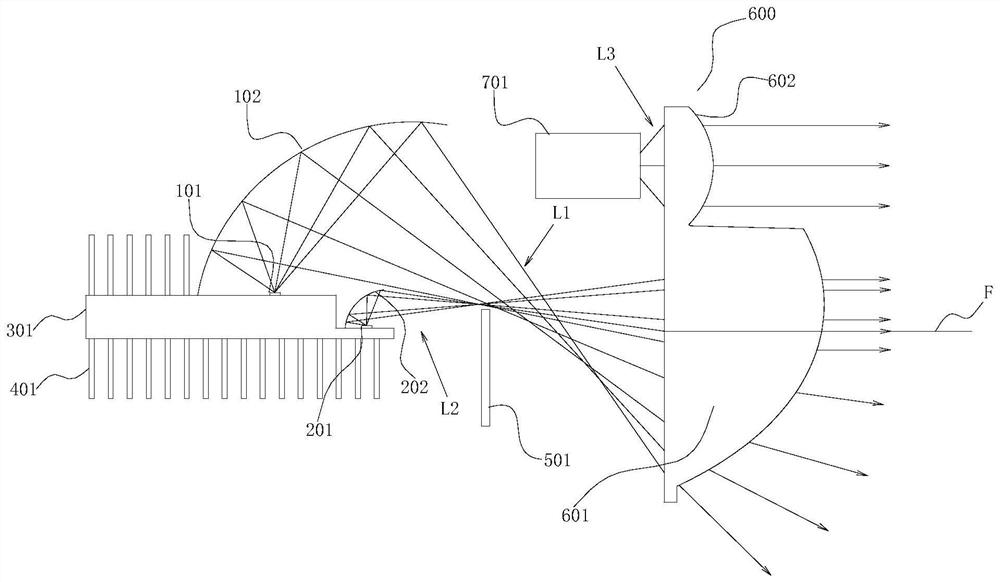

[0057] Such as image 3 As shown, Embodiment 3 provides an automobile headlight, which is improved on the solution of Embodiment 1, and its general configuration is basically the same as that of Embodiment 2. The automobile headlamp includes a heat dissipation substrate 301, a low beam incident optical system, a high beam incident optical system, a light output device 600, a far and low beam conversion device 501, a cooling fin 401, and an auxiliary high beam incident optical system. Different from Embodiment 2, the auxiliary high beam light source in Embodiment 3 is an LED light source.

[0058] Specifically, the auxiliary high beam incident optical system is used to generate the auxiliary high beam L3, the auxiliary high beam incident optical system includes an auxiliary high beam light source 701, and the auxiliary high beam L3 emitted by the LED light source is incident on the second output light lens 602 . The second light output lens 602 is used to collect the auxiliar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com