Silver-copper bimetallic thin film for light anode and laser-induced membrane-changing method

A laser-induced film replacement and bimetal technology, applied in the field of solar cells, can solve the problems of long preparation time and high cost, and achieve the effect of alleviating energy pressure, reducing over-reliance, and promoting green and low-cost development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

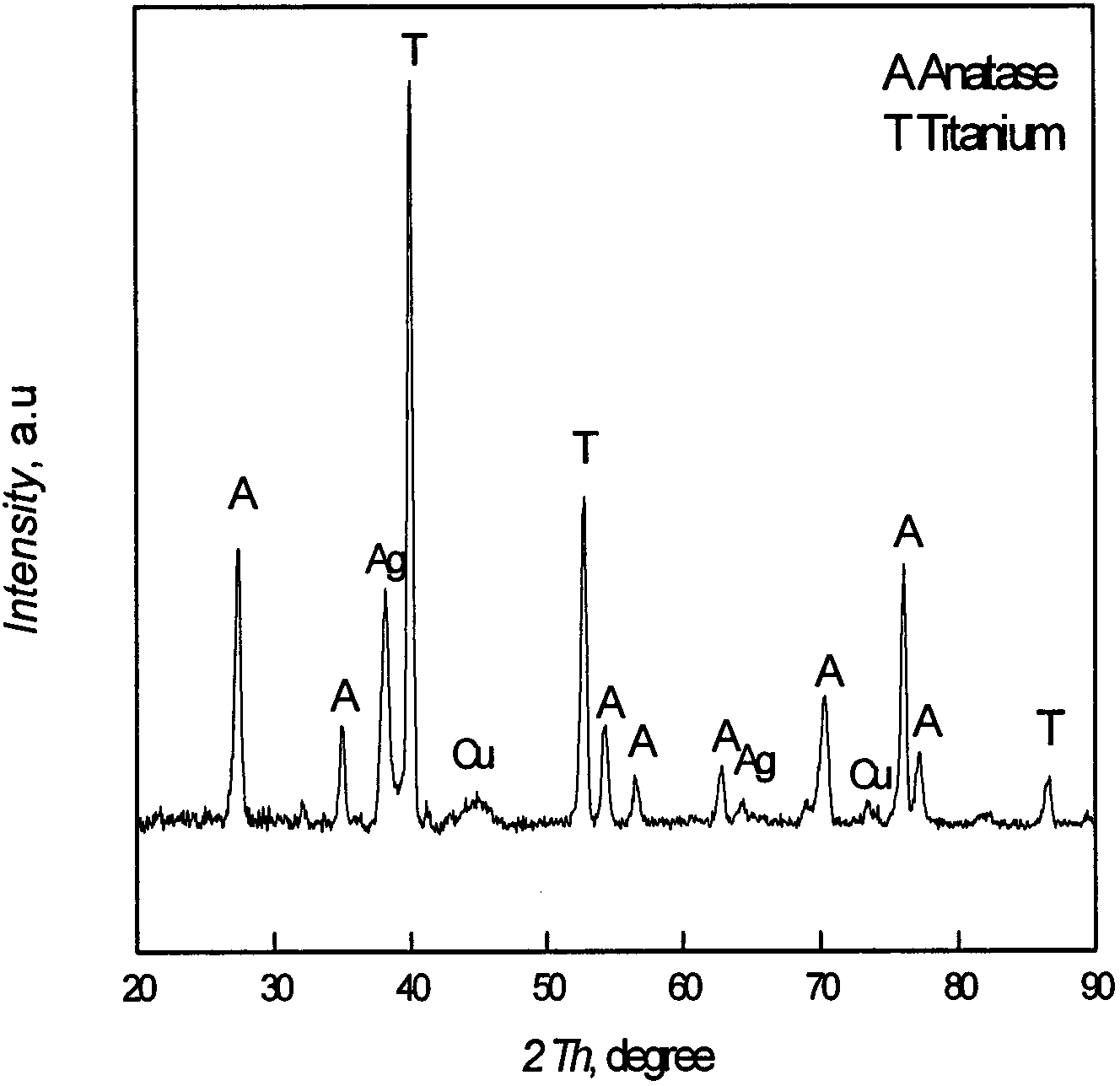

[0038] This embodiment is a silver-copper bimetallic thin film modified TiO 2 Photoanode, the size of the modified photoanode is 1cm×1cm.

[0039] The molar ratio of silver to copper in the silver-copper bimetallic thin film of the photoanode proposed in this embodiment is 1:1.

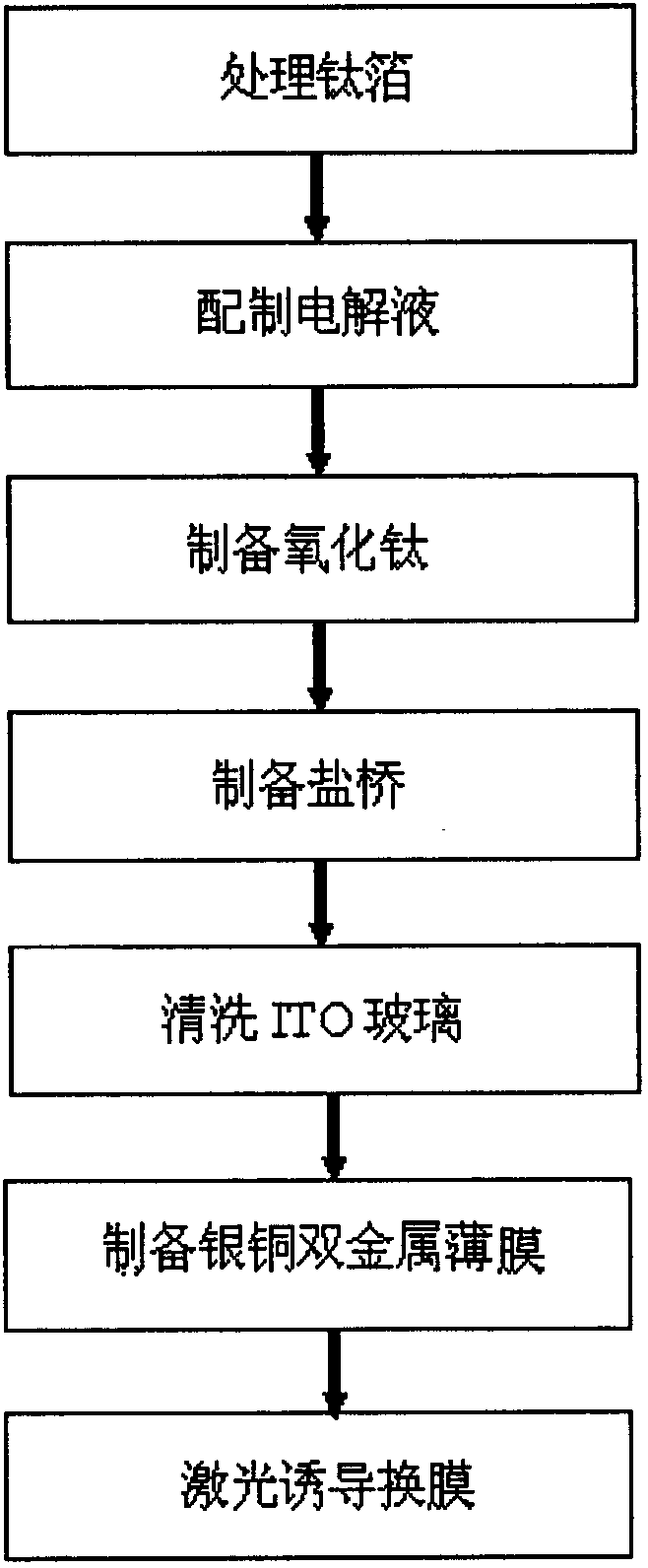

[0040] This embodiment also proposes a method for laser-induced film replacement of photoanode films, which uses the above-mentioned silver and copper bimetallic films to modify TiO by laser-induced film replacement. 2 Photoanode, the specific process is as follows:

[0041] Step 1, processing the titanium foil: Cut the titanium foil into strips of 1 cm×5 cm, polish, and ultrasonically clean with acetone, absolute ethanol and deionized water for 5 minutes each; the ultrasonic power is 200W.

[0042] Step 2, prepare electrolyte: said electrolyte includes polishing electrolyte, electrodeposition electrolyte and test electrolyte. The polishing electrolyte is composed of 5% hydrofluoric acid, 45% nitri...

Embodiment 2

[0049] This embodiment is a silver-copper bimetallic thin film modified TiO 2 Photoanode, the size of the modified photoanode is 1cm×1cm.

[0050] The molar ratio of silver to copper in the silver-copper bimetallic thin film of the photoanode proposed in this embodiment is 7:3.

[0051] This embodiment also proposes a method for laser-induced film replacement of photoanode films, which uses the above-mentioned silver and copper bimetallic films to modify TiO by laser-induced film replacement. 2 Photoanode, the specific process is as follows:

[0052] Step 1, processing the titanium foil: Cut the titanium foil into strips of 1 cm×5 cm, polish, and ultrasonically clean with acetone, absolute ethanol and deionized water for 5 minutes each; the ultrasonic power is 200W.

[0053] Step 2, prepare electrolyte: said electrolyte includes polishing electrolyte, electrodeposition electrolyte and test electrolyte. The polishing electrolyte is composed of 5% hydrofluoric acid, 45% nitri...

Embodiment 3

[0060] This embodiment is a silver-copper bimetallic thin film modified TiO 2 Photoanode, the size of the modified photoanode is 1cm×1cm.

[0061] The molar ratio of silver to copper in the silver-copper bimetallic thin film of the photoanode proposed in this embodiment is 2:8.

[0062] This embodiment also proposes a method for laser-induced film replacement of photoanode films, which uses the above-mentioned silver and copper bimetallic films to modify TiO by laser-induced film replacement. 2 Photoanode, the specific process is as follows:

[0063] Step 1, processing the titanium foil: Cut the titanium foil into strips of 1 cm×5 cm, polish, and ultrasonically clean with acetone, absolute ethanol and deionized water for 5 minutes each; the ultrasonic power is 200W.

[0064]Step 2, prepare electrolyte: said electrolyte includes polishing electrolyte, electrodeposition electrolyte and test electrolyte. The polishing electrolyte is composed of 5% hydrofluoric acid, 45% nitric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com