One-bath dyeing solution and dyeing method of nylon and wool mixed fiber

A technology of mixing fibers and nylon, which is applied in the field of textile dyeing and finishing, can solve the problems of difficulty in dyeing the same color and large difference in optimal process conditions, etc., to achieve the difficulty of solving the same color, slow down the dyeing rate, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

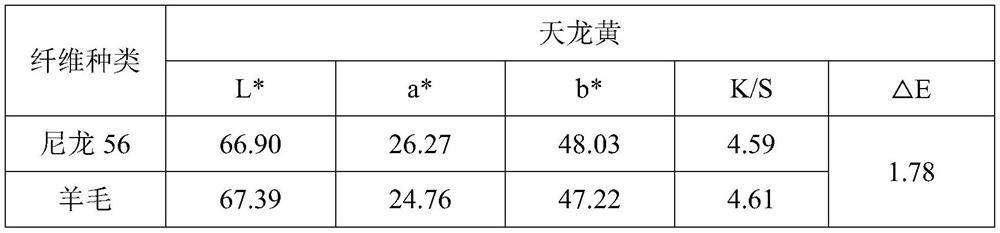

Embodiment 1

[0031] Step 1: Pretreatment: Put the mixed fiber of nylon 56 and wool to be dyed into 50°C water, pre-wet for 10 minutes, and then drain.

[0032] Step 2: Dyeing with acid dye: based on the total amount of the dye solution, the formula of the dye solution is: 1% owf of tianlong yellow dye, 0.1g / L of sodium lauryl sulfate, and polyethylene glycol of 0.005g / L 4000, JFC 0.1g / L, pH=3 acetic acid / sodium acetate buffer solution. Take the dye liquid into a beaker, then add acetic acid / sodium acetate buffer solution with pH=3, sodium lauryl sulfate solid and other medicines and stir evenly, and finally put the pretreated nylon 56 and wool mixed fiber into the prepared In the dyeing liquor, the mass ratio of mixed fiber and dyeing liquor is 1:50. The temperature was raised to 100° C. at 1° C. / min, and then kept for 60 minutes.

[0033] Step 3: Color fixation: take out the dyed mixed fiber, squeeze out the water with 0.05MPa, then wash with cold water, and use Selefa N-HFG 3% owf to f...

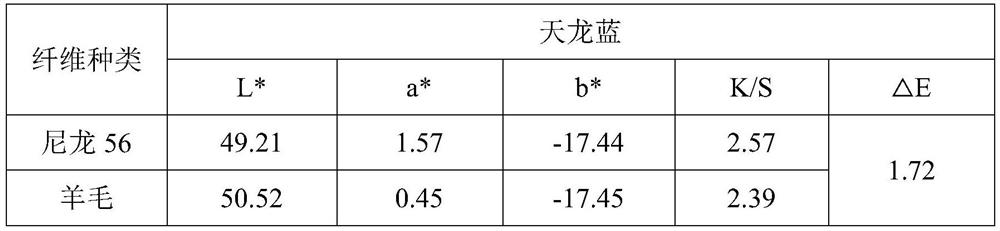

Embodiment 2

[0038] Step 1: Pretreatment: Put the mixed fiber of nylon 56 and wool to be dyed into 50°C water, pre-wet for 20 minutes, and then drain.

[0039]Step 2: acid dyeing: based on the total amount of the dyeing solution, the formula of the dyeing solution is: 2% owf of sky dragon blue dye, 0.5g / L of sodium lauryl sulfate, polyethylene glycol of 0.001g / L 2000, JFC 0.1g / L, pH=4 acetic acid / sodium acetate buffer solution. Take the dye liquid into a beaker, then add acetic acid / sodium acetate buffer solution with pH=4, solid sodium lauryl sulfate and other medicines and stir evenly, and finally put the pretreated nylon 56 and wool mixed fiber into the prepared In the dyeing liquor, the mass ratio of mixed fiber and dyeing liquor is 1:40. The temperature was raised to 80° C. at 1° C. / min and then kept for 60 minutes.

[0040] Step 3: Color fixation: take out the dyed mixed fiber, squeeze out the water with 0.1MPa, and then wash with cold water, and use Selefa N-HFG 2% owf to fix the ...

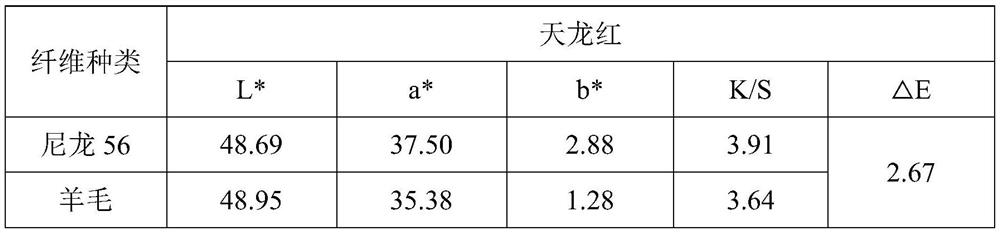

Embodiment 3

[0045] Step 1: Pretreatment: Put the mixed fiber of nylon 56 and wool to be dyed into water at 40°C, pre-wet for 10 minutes, and then drain.

[0046] Step 2: Dyeing with acid dye: Based on the total amount of the dye solution, the formula of the dye solution is: 1% owf of Tianlong red dye, 2 g / L of sodium dodecylbenzene sulfonate, 0.1 g / L of polyethylene glycol Alcohol 400, JFC 0.1g / L, pH=4 acetic acid / sodium acetate buffer solution. Take the dye liquid into a beaker, then add acetic acid / sodium acetate buffer solution with pH=4, sodium dodecylbenzenesulfonate solid and other medicines and stir evenly, and finally put the pretreated nylon 56 and wool mixed loose fiber Into the prepared dye liquor, the mass ratio of mixed fiber and dye liquor is 1:50. The temperature was raised to 100° C. at 1° C. / min, and then kept for 60 minutes. After dyeing, rinse with water, wash in warm water, wash in cold water, and tumble dry.

[0047] Step 3: Color fixation: take out the mixed fiber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com