Oiling device for leather processing

A leather and oil tank technology, applied in the field of oiling devices for leather processing, can solve the problems of low oiling efficiency and uneven oiling, achieve the effects of thorough oiling, save time, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

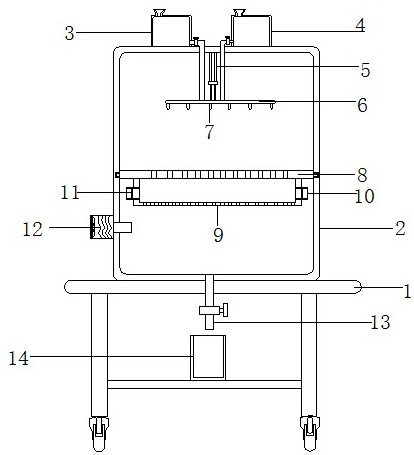

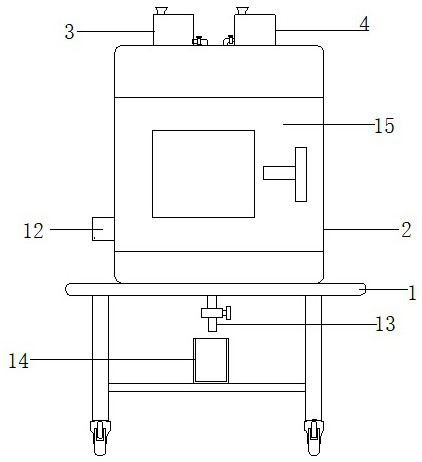

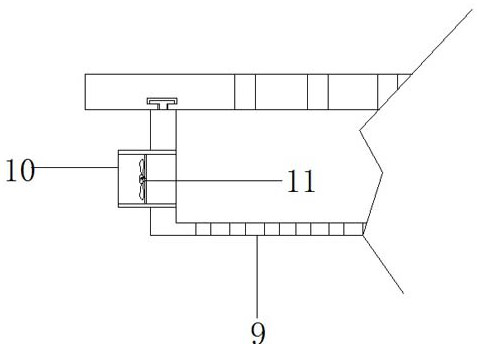

[0019] Embodiment 1, with reference to Figure 1-3 , an oiling device for leather processing, comprising a bottom plate 1, a box body 2 is welded on the top outer wall of the bottom plate 1, an oil tank 3 and a cleaning box 4 are welded on the top outer wall of the box body 2, and a leather protection box is contained in the oil tank 3 Oil, and cleaning agent is contained in the cleaning box 4, the oil in the oil tank 3 is sprayed through the atomizing nozzle 7, and the leather is sprayed. Compared with the traditional device, the oiling is more thorough, and it saves time and improves work efficiency. The cleaning agent in the cleaning box 4 is ejected through the atomizing nozzle 7 after the oiling is completed, and the inside of the box body 2 is flushed to keep the inside of the box body 2 clean. The inner wall of the top of the box body 2 is welded with a push rod motor 5, and The bottom of the push rod motor 5 is welded with a storage pipe 6, and the outer wall of the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com